Driving wheel with shock absorption function

A driving wheel and function technology, applied in the field of wheels, can solve the problems of low safety factor and complex shock absorption design, and achieve the effect of simple structure and shock absorption function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

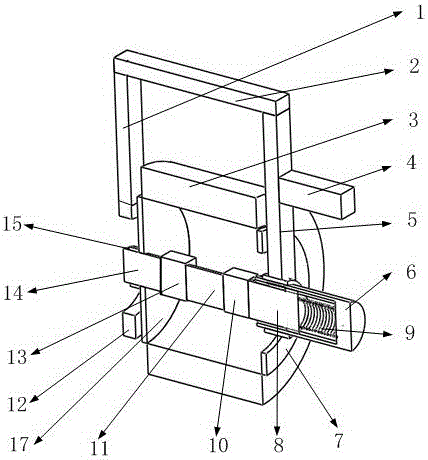

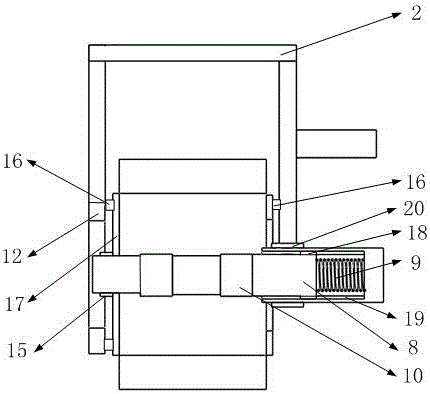

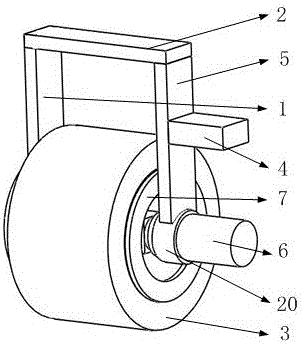

[0018] Such as figure 1 , 2 As shown, it includes a second side brace 1, a cross brace 2, a wheel 3, a mounting frame 4, a first side brace 5, a transmission shaft 6, a ring plate 7, a first rotating shaft 8, a return spring 9, and a first universal joint 10. Second rotating shaft 11, side retaining ring 12, second universal joint 13, wheel rotating shaft 14, ferrule 15, ball bearing 16, wheel support 17, key 18, keyway 19, ring sleeve 20, wherein as figure 1 , 3 As shown, one end of the first side brace 5 is installed on the transmission shaft 6 through the ring sleeve 20, the cross brace 2 is installed on the upper end of the first side brace 5, the second side brace 1 is installed on the lower side of one end of the cross brace 2, and the first side Support 5, horizontal support 2, and second side support 1 form a door shape; as figure 1 , 2 As shown, the side retaining ring 12 is installed at the lower end of the second side support 1; as figure 1 , 2 , 7, wheel supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com