Multi-functional wagon with function of automatic loading and unloading steel rails and using method of multi-functional wagon

A railway freight car, automatic loading and unloading technology, applied in railway car body parts, transportation passenger cars, transportation and packaging, etc., can solve the problems of rising basic costs, low single-vehicle transportation volume, messy loading, etc., to reduce the investment amount and construction personnel. Quantity and effect of reducing purchase amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

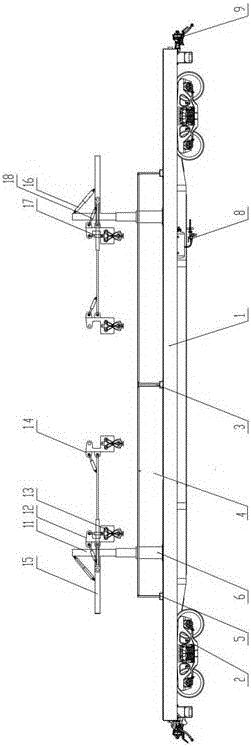

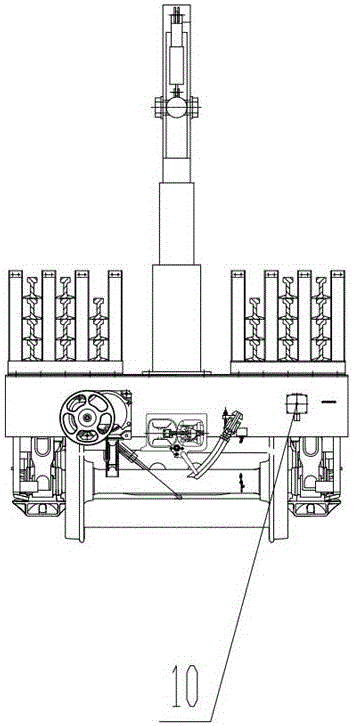

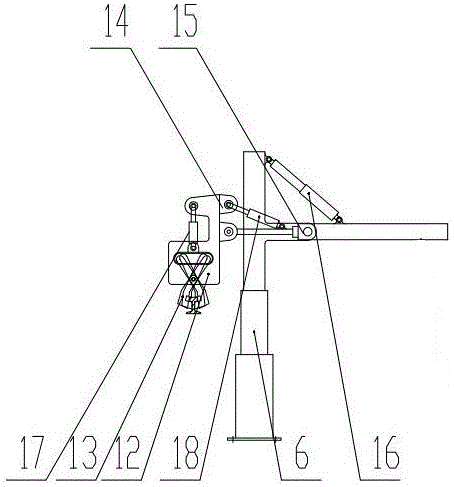

[0020] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be described in further detail: as figure 1 , figure 2 and image 3 Shown is a multifunctional railway freight car with the function of automatically loading and unloading rails. The freight car includes an underframe 1, a bogie 2, a rail fixing mechanism, and a rail loading and unloading mechanism. The two bogies 2 are respectively arranged on the underframe 1 The upper surface of the underframe 1 is provided with a steel floor, the rail fixing mechanism and the rail loading and unloading mechanism are both arranged on the steel floor, and the rail loading and unloading mechanism is an oil cylinder driven mechanism.

[0021] The rail fixing mechanism comprises a spacer post 3, a connecting rod 4 and a base 5, and three rows of spacer posts 3 are evenly spaced along the length direction of the undercarriage 1 on the underframe 1, and the quantity of each row of spacer po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com