Device and method for installing servo mechanism in compact space of rocket cabin section

A technology of servo mechanism and installation device, which is applied to ground devices, aircraft parts, transportation and packaging, etc., can solve the problems that the installation requirements of the launch vehicle servo mechanism cannot be met, the manual handling process is complicated, and the engine pipeline structure is complicated. The effect of stable and reliable hoisting process, reliable control of hoisting speed, and standardized installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

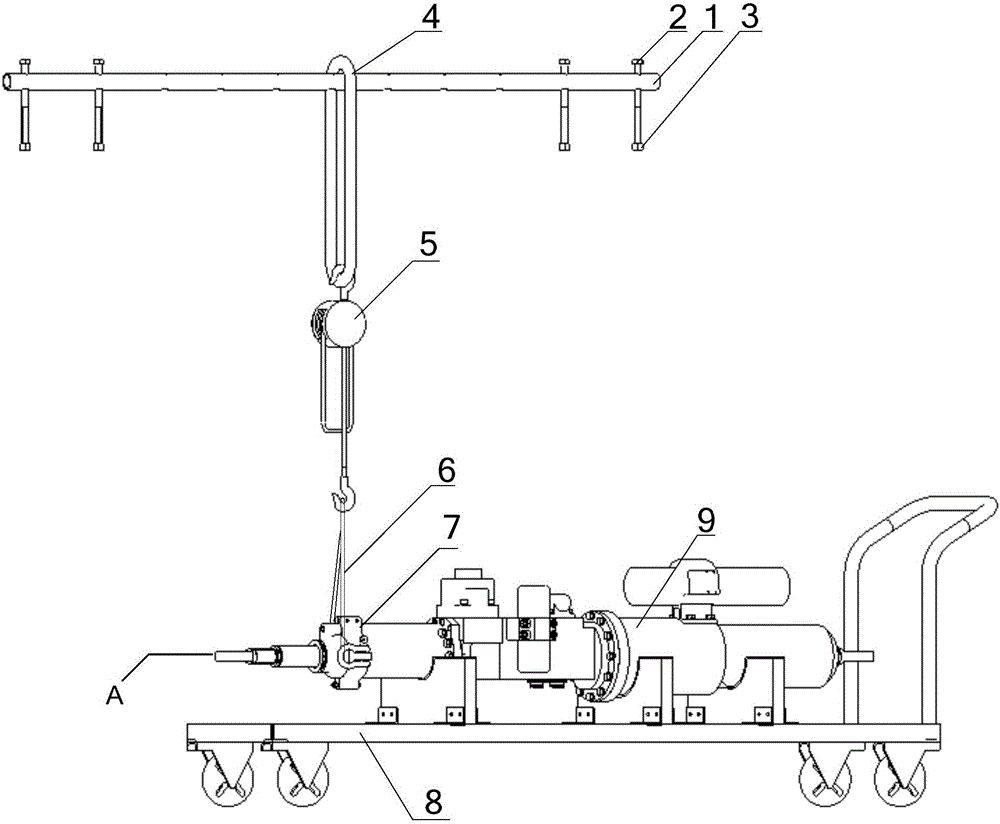

[0058] The lengths of the first sling 4 and the second sling 6 are 0.5 m and 0.8 m, respectively.

[0059] The first sling 4 is fixed at the position 2 / 5 of the left end of the hanging beam 1, that is, the distance from the fixed position of the first sling 4 to the left end of the hanging beam is 2 / 5 of the length of the hanging beam 1.

[0060] The suspension beam 1 is a cylindrical steel pipe with several through holes distributed, the length of the suspension beam 1 is 1.75 m, and the spacing of the through holes on the suspension beam 1 is 0.2 m. Two studs 2 at each end of the hanging beam 1.

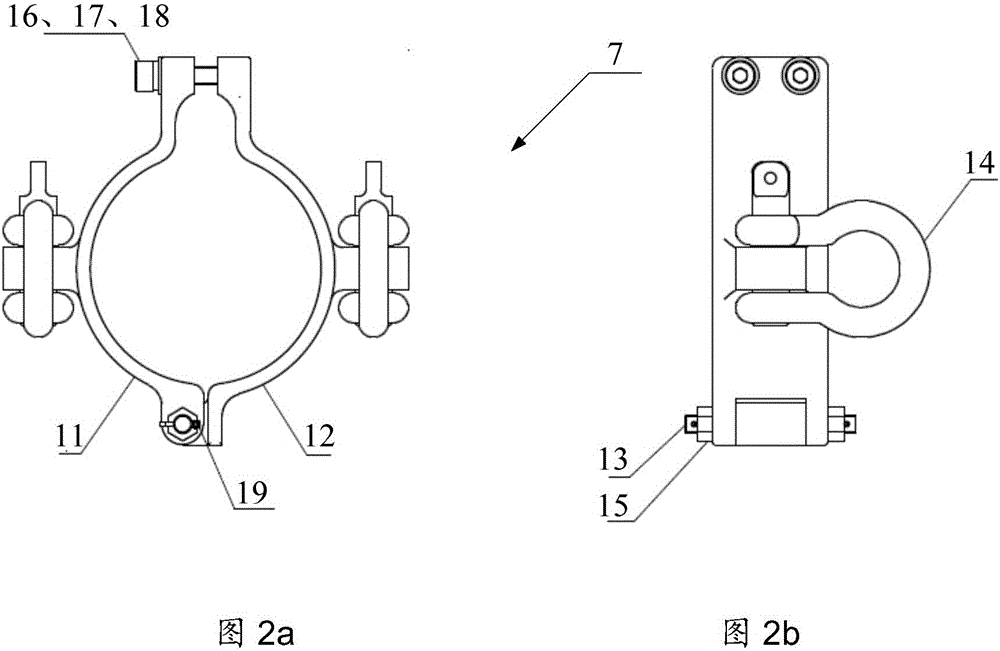

[0061] The height of the boss at one end of the second clamp 12 and the depth of the groove at one end of the first clamp 11 are 18 mm, and the left-right gap after assembly is 0.2-0.5 mm.

[0062] The material of the hanging beam 1 and the clamp assembly 7 is stainless steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com