A kind of high temperature resistant epoxy resin composite phase change material and preparation method thereof

A composite phase change material and epoxy resin technology, which is applied in the field of composite materials, can solve problems such as device wear, epoxy resin is easy to bond, and road performance is low, achieving stable performance, lower quality requirements, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

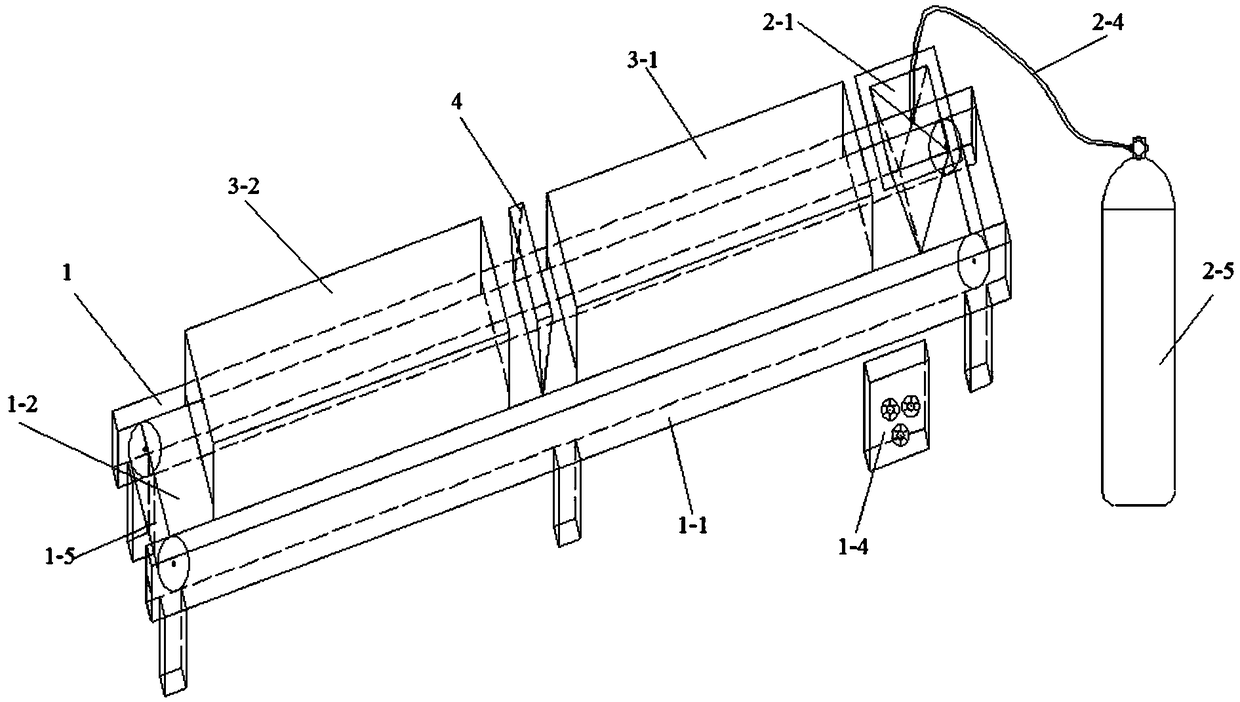

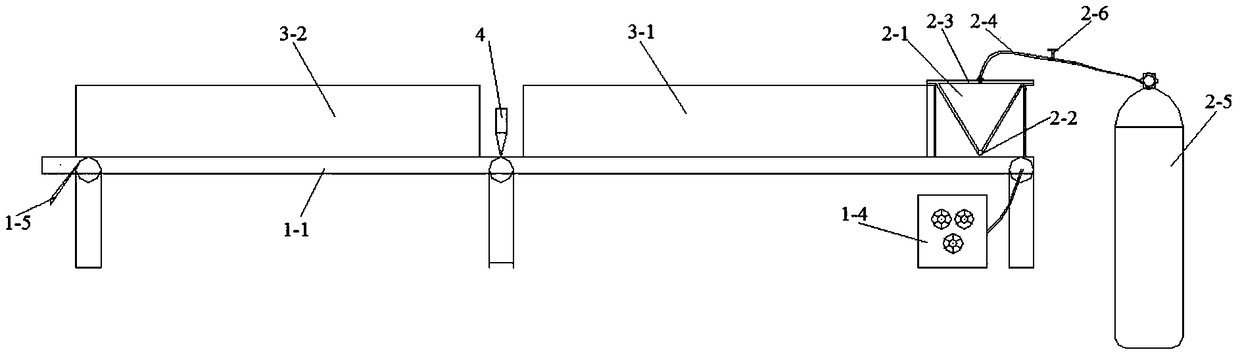

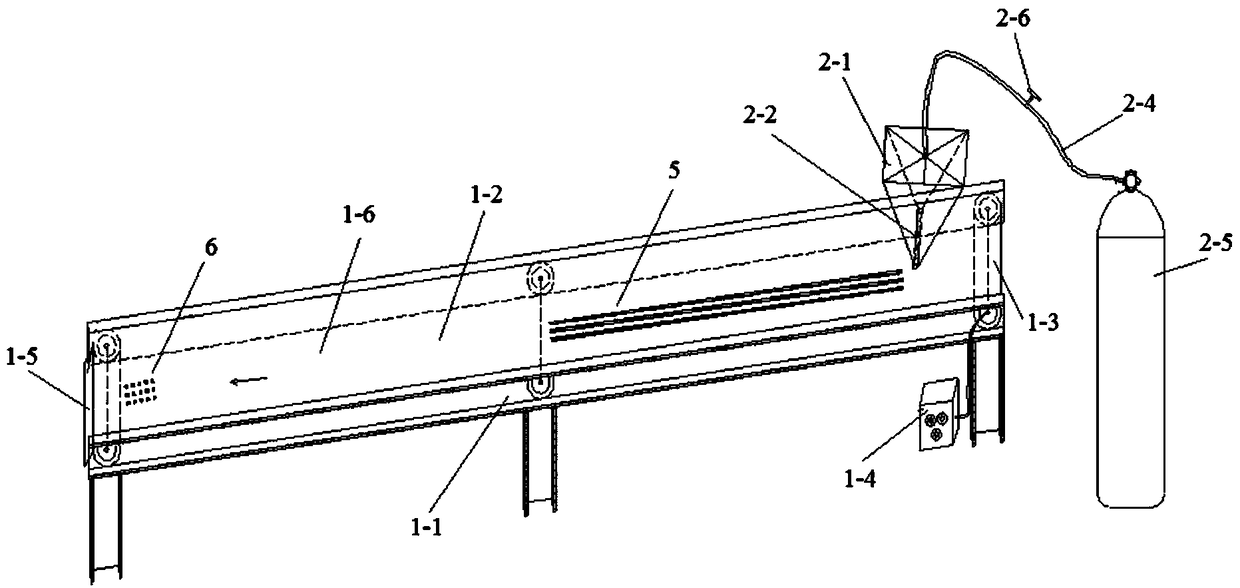

[0073] Comply with the above technical solutions, such as Figure 1 to Figure 6 As shown, the present embodiment provides a kind of granulation device, including a transmission unit 1, the transmission unit 1 includes a support frame 1-1, and a conveyor belt 1-2 is installed on the support frame 1-1, and the conveyor belt 1 The driving shaft 1-3 of -2 is connected with the speed control box 1-4; it also includes a feeding unit 2, a heating unit 3 and a cutting unit 4; the heating unit 3 and the cutting unit are installed on the support frame 1-1 Unit 4, the heating unit 3 includes a front heating unit 3-1 and a rear heating unit 3-2, and the cutting unit 4 is located between the front heating unit 3-1 and the rear heating unit 3-2;

[0074] The feeding unit 2 includes a wedge-shaped hopper 2-1. The wedge-shaped hopper 2-1 is installed on the front support frame 1-1 of the conveyor belt 1-2. The lower part of the wedge-shaped hopper 2-1 is provided with a discharge hole 2-2. Th...

Embodiment 2

[0090] The present embodiment provides a kind of phase-change microcapsules, in parts by weight, made of the following raw materials: 43 parts of phase-change materials, 21.5 parts of white carbon black particles, 3 parts of ethyl cellulose, 0.5 parts of plasticizer, 32 parts of solvent-based additives.

[0091] in:

[0092] The phase change material is paraffin, which can also be replaced by C12-C20 normal alkanes;

[0093] The plasticizer is a phthalate plasticizer, and a sebacate plasticizer, a citrate plasticizer, a propylene glycol sebacate polyester plasticizer or a phthalate polyester plasticizer can also be used. Replacement of similar plasticizers;

[0094] The solvent-based additive is toluene, which can also be replaced by methanol, absolute ethanol, cyclohexane or acetone.

[0095] The preparation method of phase change microcapsules is as follows:

[0096] Step 1.1, adding a plasticizer to the solvent-based additive according to the ratio of raw materials, sti...

Embodiment 3

[0103] This example provides a high temperature resistant epoxy resin composite phase change material, which is made of the following raw materials in parts by weight: 45 parts of phase change microcapsules, 45 parts of epoxy resin, and 10 parts of curing agent.

[0104] in:

[0105] Phase-change microcapsules adopt the phase-change microcapsules in Example 2.

[0106] The epoxy resin is a bisphenol A type epoxy resin.

[0107] The curing agent is ethylenediamine.

[0108] The preparation method of the high temperature resistant epoxy resin composite phase change material of this embodiment adopts the granulation device described in Example 1, and the preparation method specifically includes the following steps:

[0109] Step 1: Add diluent and curing agent weighed according to the ratio of raw materials to the epoxy resin in turn, stir for 3 minutes at 450 rpm, then slowly add phase-change microcapsules, stir for 3 minutes at 100 rpm, and disperse evenly. Obtain raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com