A double-channel converging side-axis powder feeding nozzle

A convergent, dual-flow technology, applied in metal material coating process, coating and other directions to achieve the effect of improving powder utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

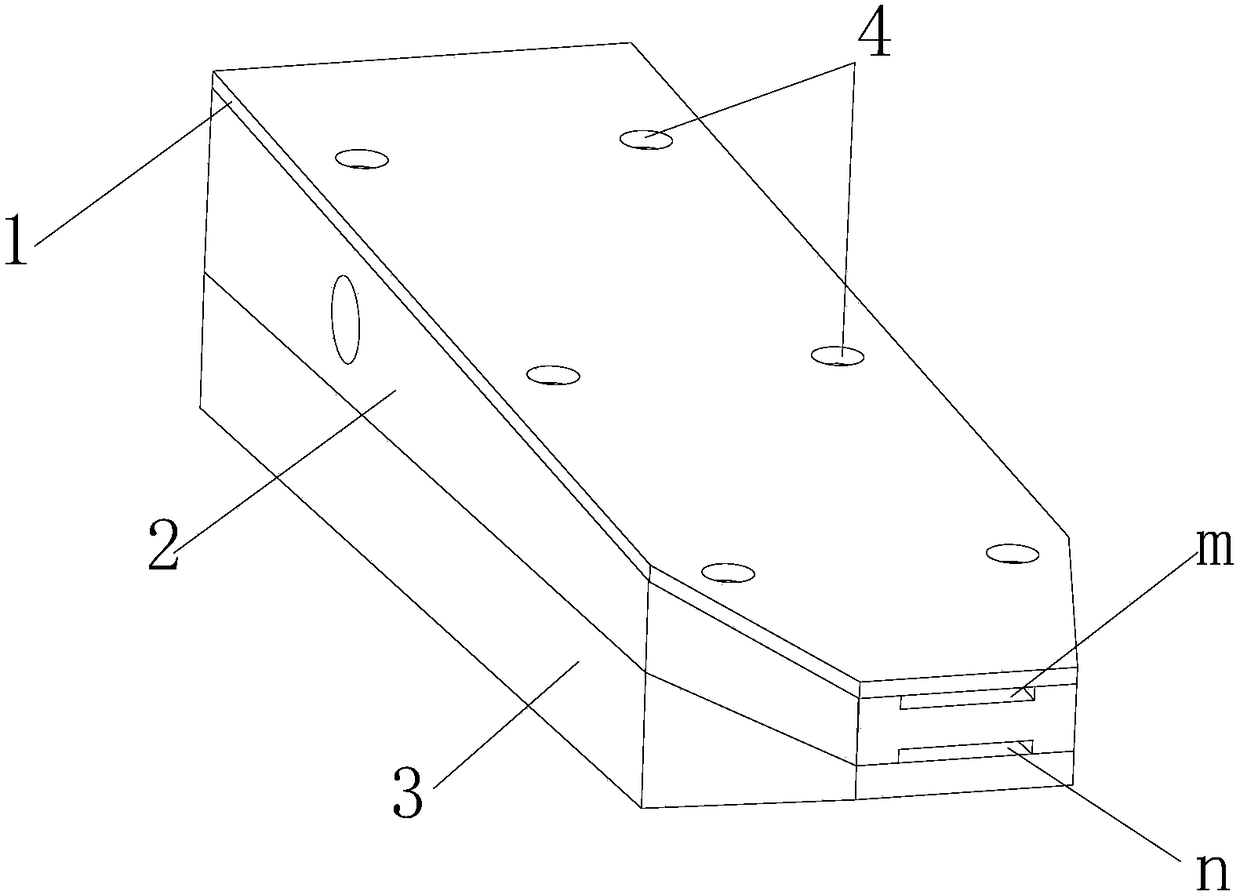

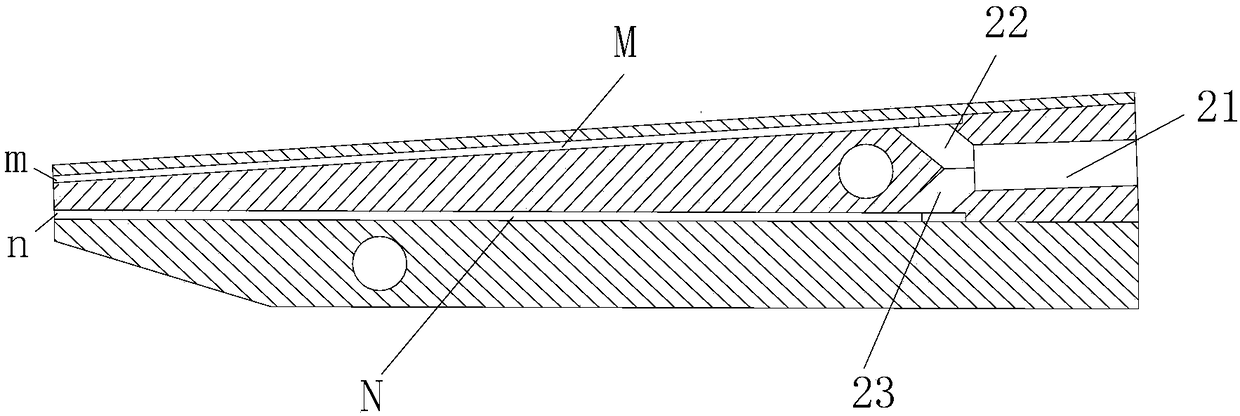

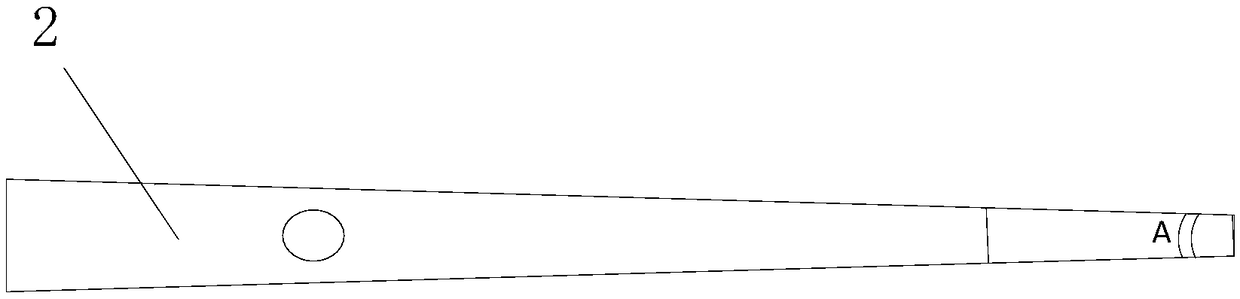

[0026] As shown in the figure, a side-axis powder feeding nozzle with a double-channel converging type includes a top plate 1, a wedge-shaped plate 2 and a bottom plate 3 that are stacked horizontally from top to bottom and fixed to each other;

[0027] The large end of the wedge-shaped plate 2 is provided with a total flow channel 21, and the inlet end of the total flow channel 21 is exposed on the side of the wedge-shaped plate 2 to form a total inlet; between the top plate 1 and the wedge-shaped plate 2, there is a The upper channel M of the upper channel M, the lower channel N extending along the bottom surface of the wedge plate 2 is provided between the base plate 3 and the wedge plate 2, the proximal end of the upper channel M communicates with the outlet end of the main channel 21 through the first branch channel 22, and the downstream The proximal end of the channel N communicates with the outlet end of the main channel 21 through the second branch channel 23, the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com