Patents

Literature

30results about How to "Solve the problem of divergence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Position estimation method based on integrated navigation of multiple sensors

ActiveCN105021198AHigh positioning accuracyCost-effectiveNavigational calculation instrumentsSimulationComputational physics

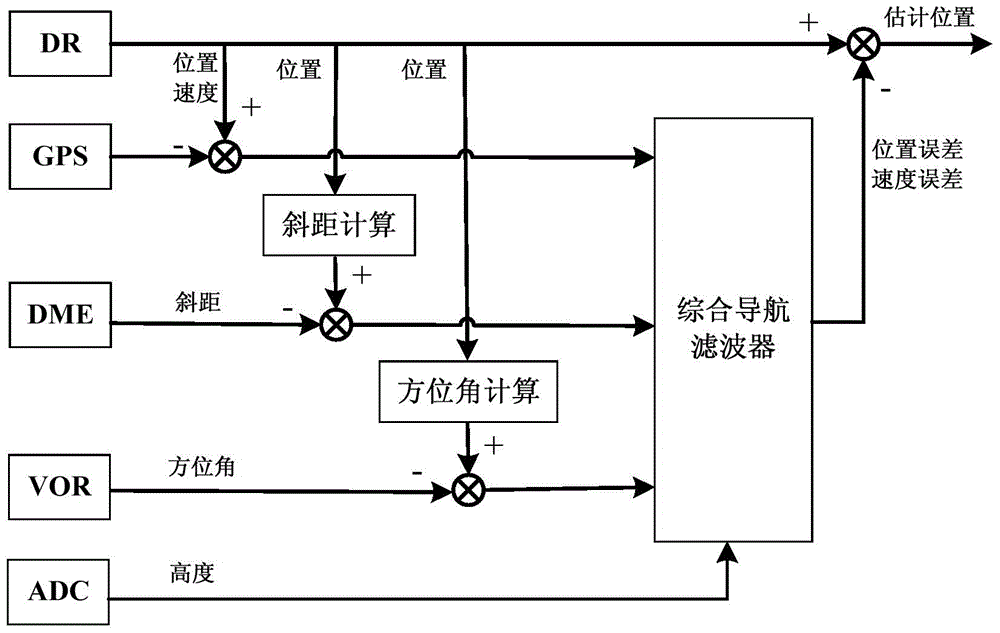

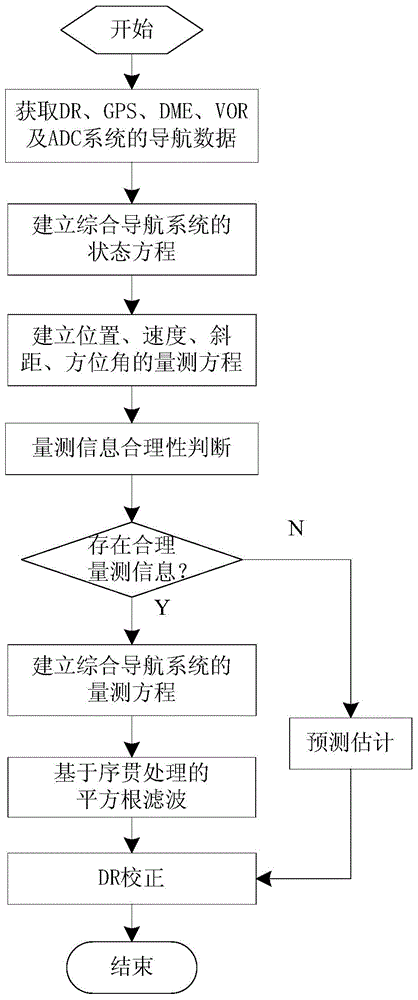

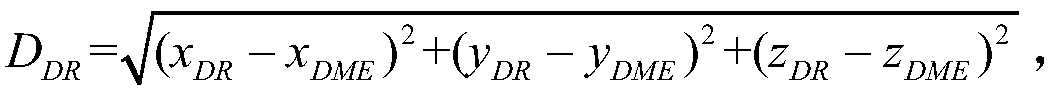

The invention discloses a position estimation method based on integrated navigation of multiple sensors. The method comprises the following steps: 1, parameters output by a DR, a GPS, a DME, a VOR and an ADC are acquired; 2, a state equation is established; 3, a position and velocity measurement equation of the GPS, a slope distance measurement equation of the DME and an azimuth measurement equation of the VOR are calculated; 4, a comprehensive measurement equation is established according to each measurement equation; 5, by combining the state equation and the comprehensive measurement equation, position error amount and velocity error amount are estimated; and 6, according to the estimated position error amount and velocity error amount, output correction is carried out on the DR system, and position estimation is finished. According to the invention, there is no need to use an inertial navigation system. The method provided by the invention has high positioning accuracy, high reliability and good real-time performance, is economic, effective and easy for engineering realization, and can meet high-precision and high-reliability positioning requirements of civil aircrafts.

Owner:上海航空电子有限责任公司

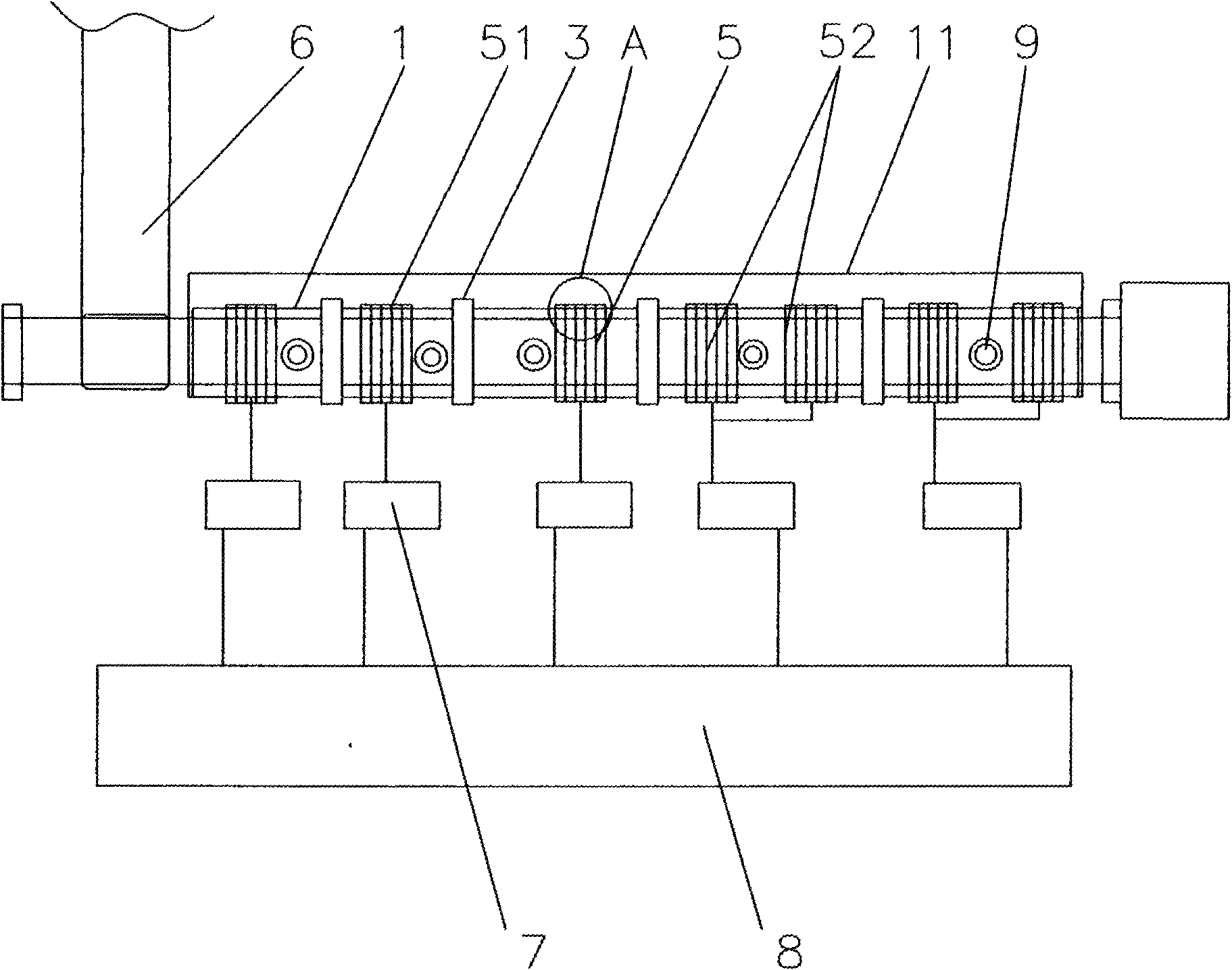

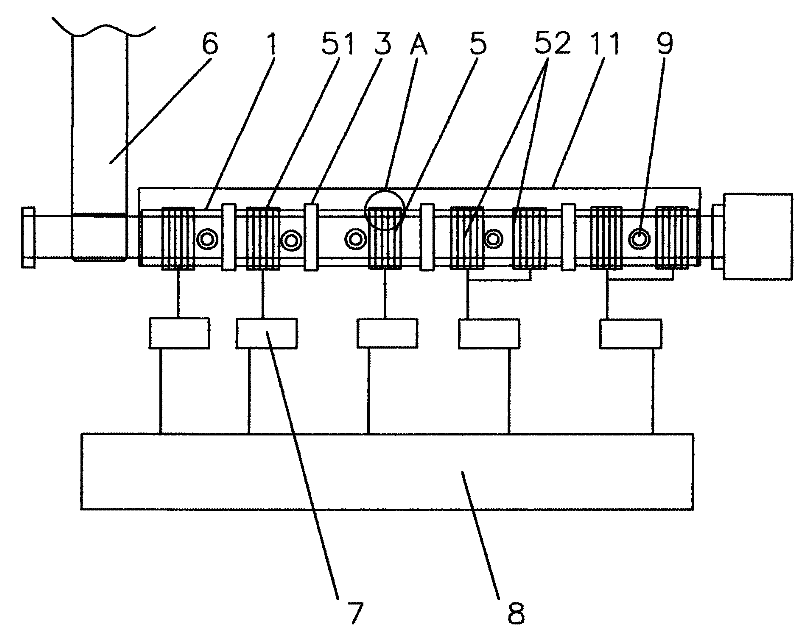

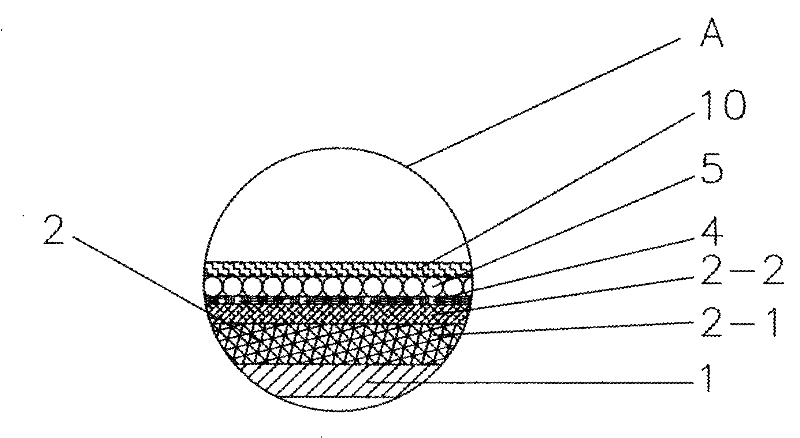

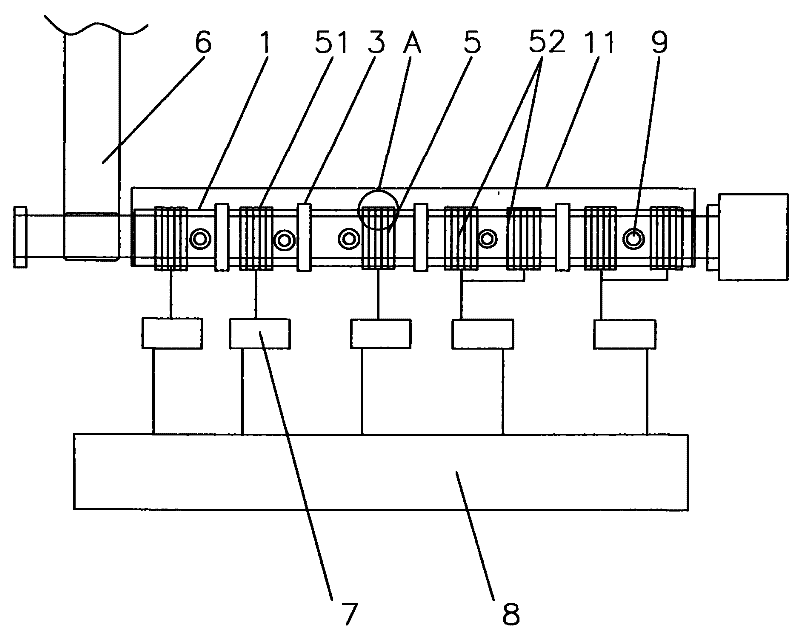

Method for heating screw cylinder of spinning machine and device thereof

ActiveCN101588657ASolve the problem of divergenceThere will be no phenomena such as aging and disconnectionCoil arrangementsArtificial thread manufacturing machinesInsulation layerMetallic materials

The method for heating a screw cylinder of a spinning machine, designed by the invention, specifically comprises that: for the screws equal to [phi]105 millimeters and below [phi]105 millimeters, electromagnetic heating is implemented in each heating region by using 220V power source; three-phase four-wire 380V power source is utilized to power apparatus above [phi]105 millimeters, and 2-4 electromagnetic heating coils are utilized to heat in each hearing region; an electromagnetic controller rectifies alternating current to direct current and converts the direct current into high-frequency current having frequency of 20-40KHz; when magnetic lines of force pass through the screw cylinder of a magnetically conductive metal material, numberless small vortexes are generated in the metal so that material in the screw cylinder reaches ideal heating effect. The screw cylinder device resulted from the invention makes use of electromagnetic induction principle to heat the screw cylinder and is provided with a heat preservation layer, a heat insulation layer and the like outside of the screw cylinder, thus solving the problem that heat is dispersed to air to maximize heat efficiency.

Owner:TONGXIANG ZHONGWEI CHEM FIBER

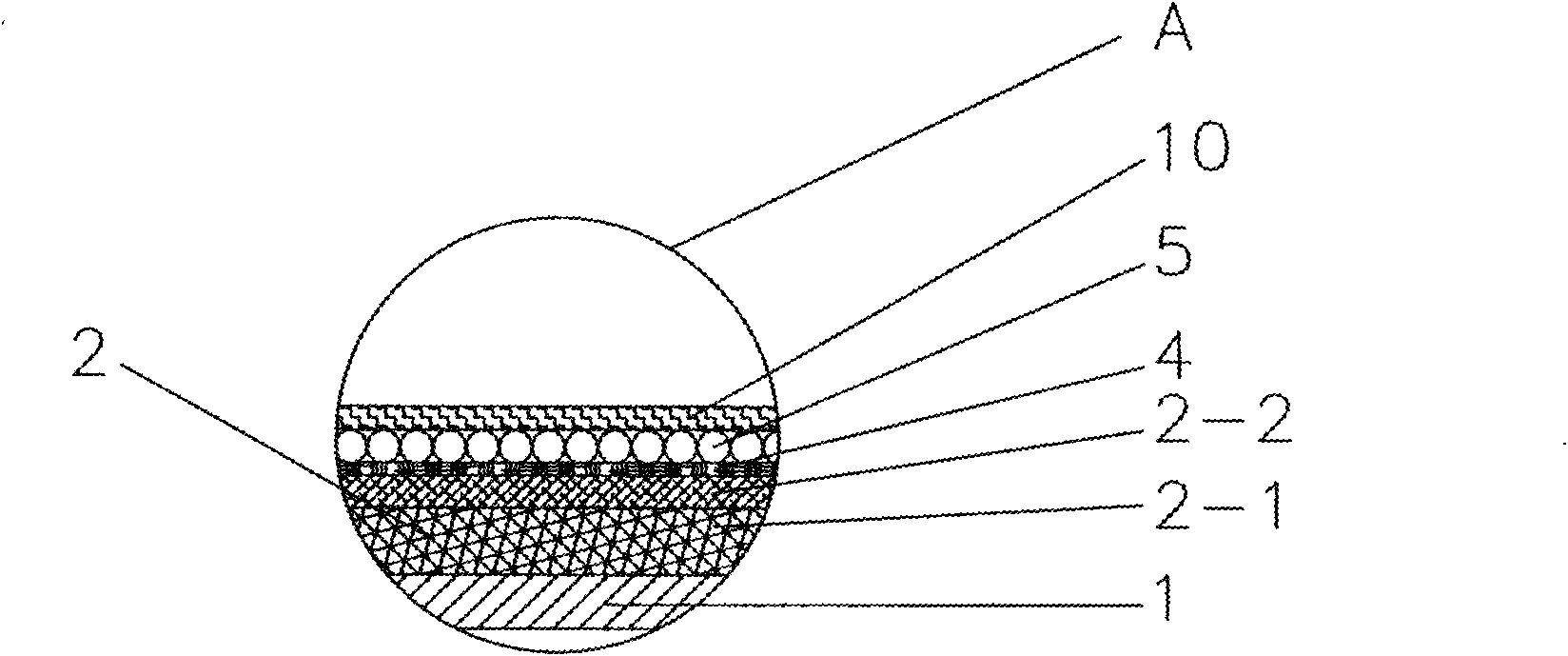

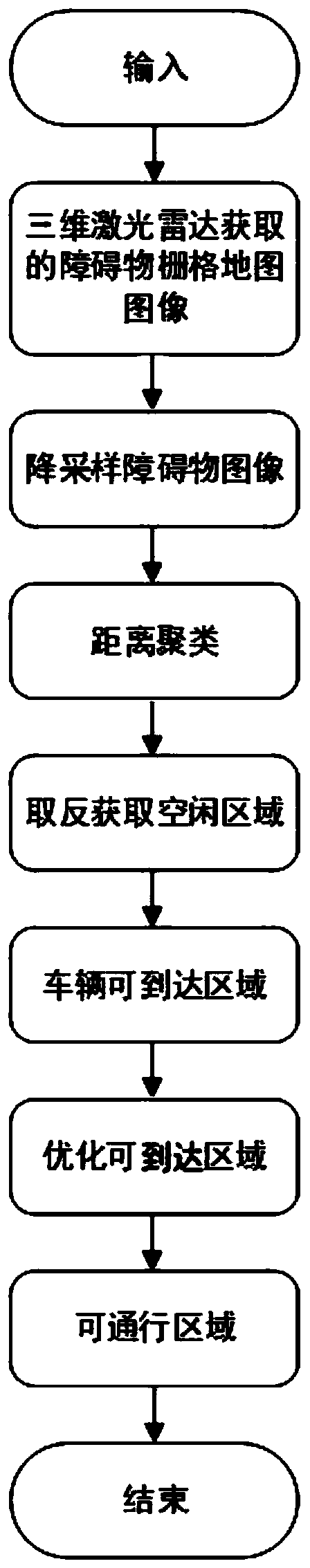

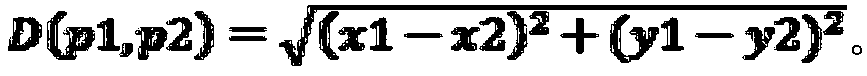

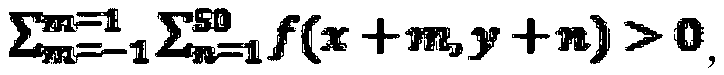

Detection method for passable area based on three-dimensional laser radar

InactiveCN109212555AOptimize the passable areaSolve the divergence of the passable areaElectromagnetic wave reradiationRegion detectionSafe driving

The invention relates to unmanned vehicles, and specifically relates to a detection method for a passable area based on a three-dimensional laser radar. The method comprises the following steps: acquiring an obstacle grid map image by a three-dimensional laser radar; clustering obstacles by using a distance function; calculating an Euclidean distance between any two obstacle points in the obstaclegrid map, and connecting the two obstacle points in a straight line if the Euclidean distance is smaller than a clustering threshold T, the points on the straight line are considered to be the obstacles; performing a reverse operation right after distance clustering to obtain an idle region; removing corners not suitable for vehicle passing in the idle region; acquiring a reachable area on an idle area starting from a vehicle position; performing down-sampling on the reachable area to return to the obstacle grid map in an original size; and optimizing the reachable area. According to the technical scheme provided by the invention, the defect that a safe driving region is difficult to divide by using boundary and point cloud smoothness features in the prior art can be effectively overcome.

Owner:合肥中科智驰科技有限公司

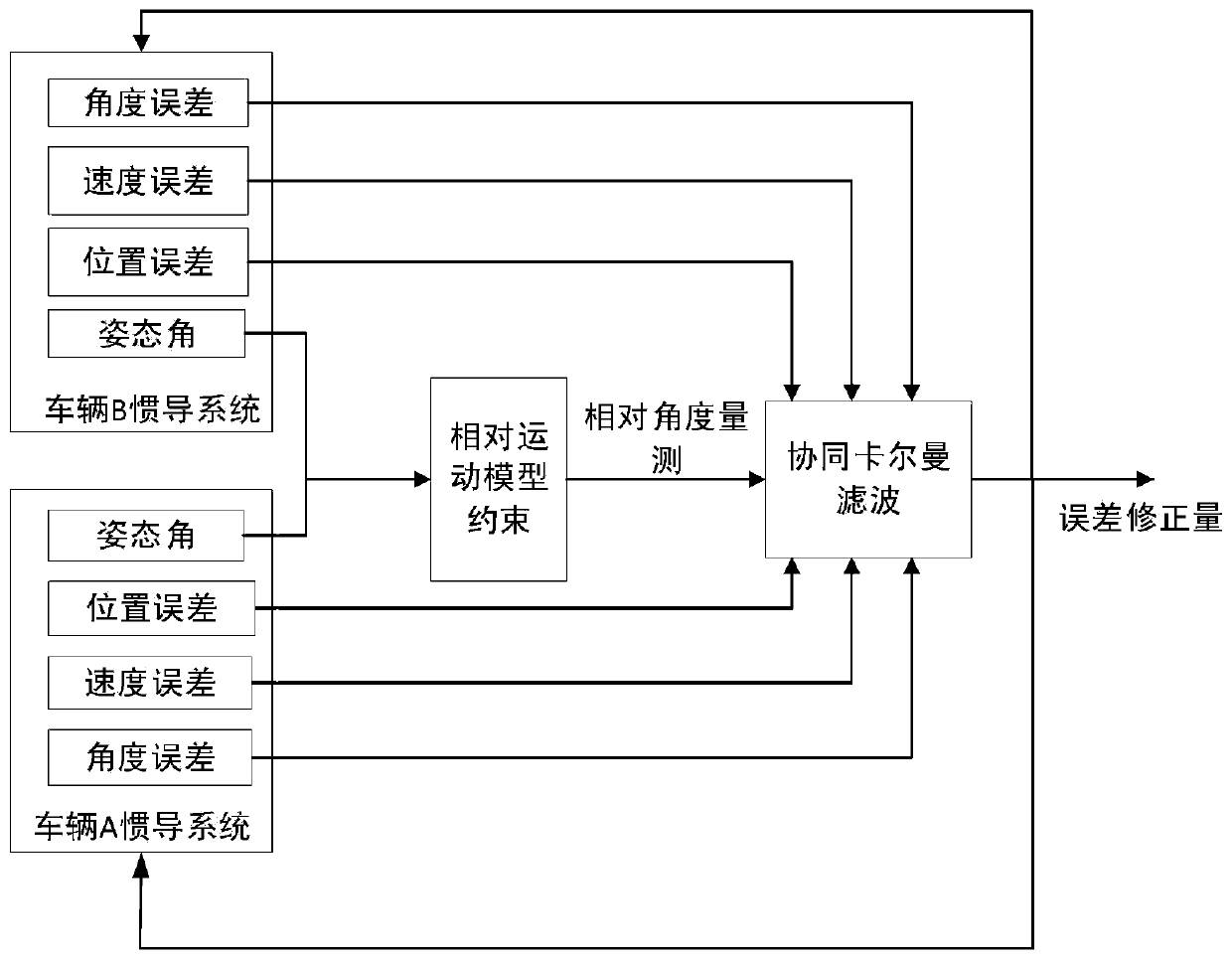

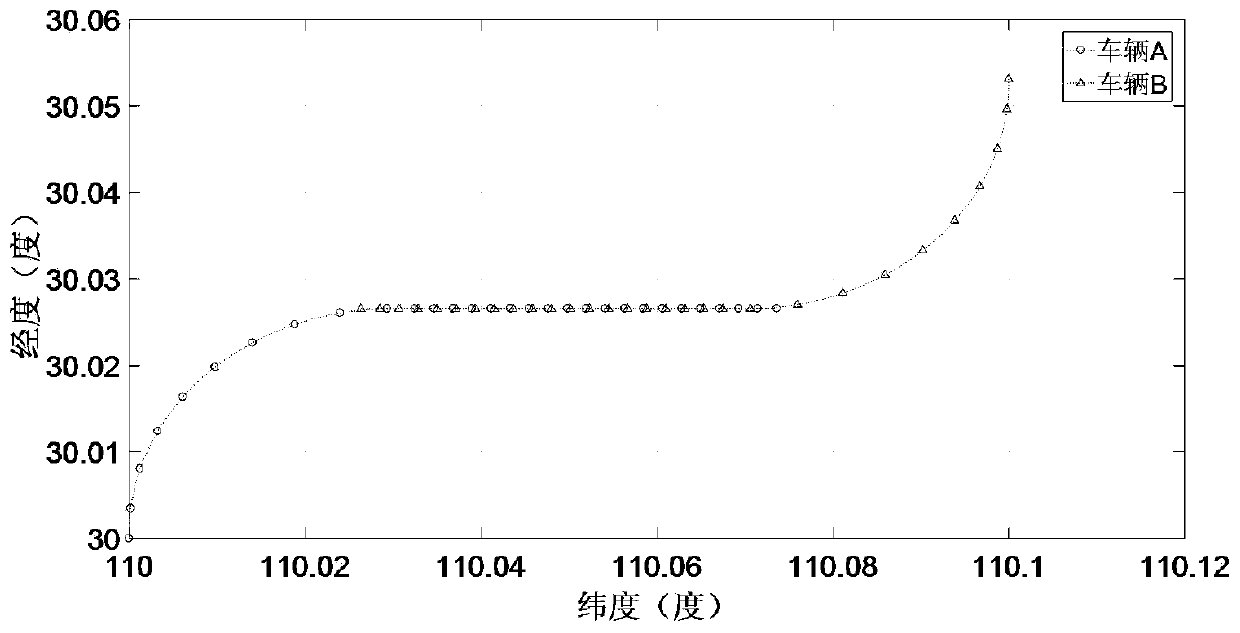

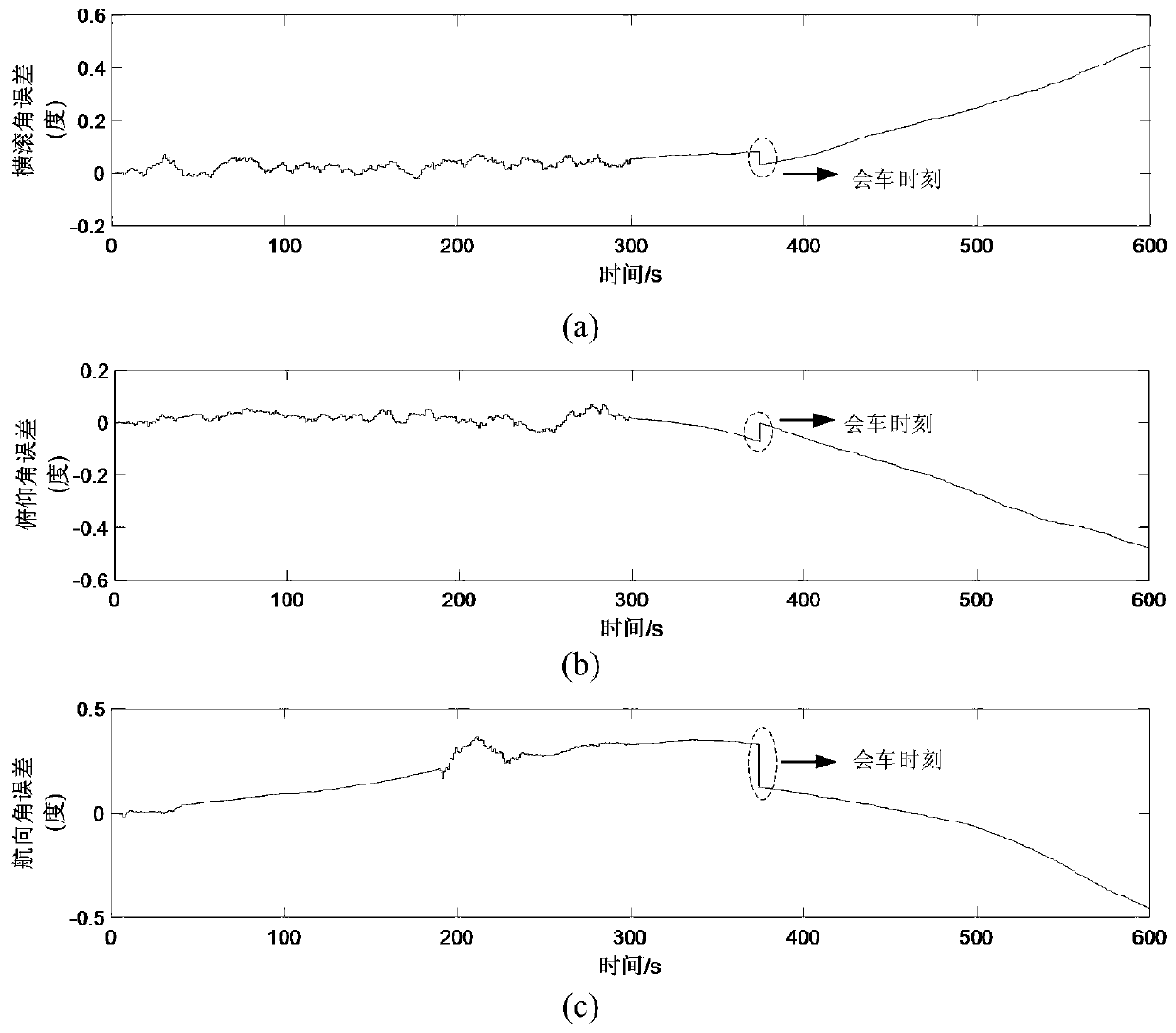

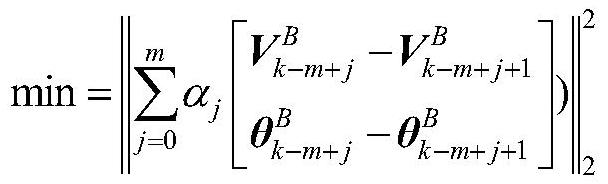

Vehicle cooperative navigation method based on relative motion model

ActiveCN110285804AHigh precisionSolve the problem of divergenceNavigation by speed/acceleration measurementsComplex mathematical operationsRelative motionNavigation system

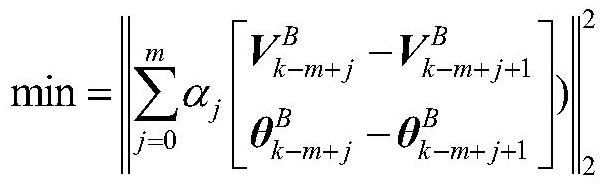

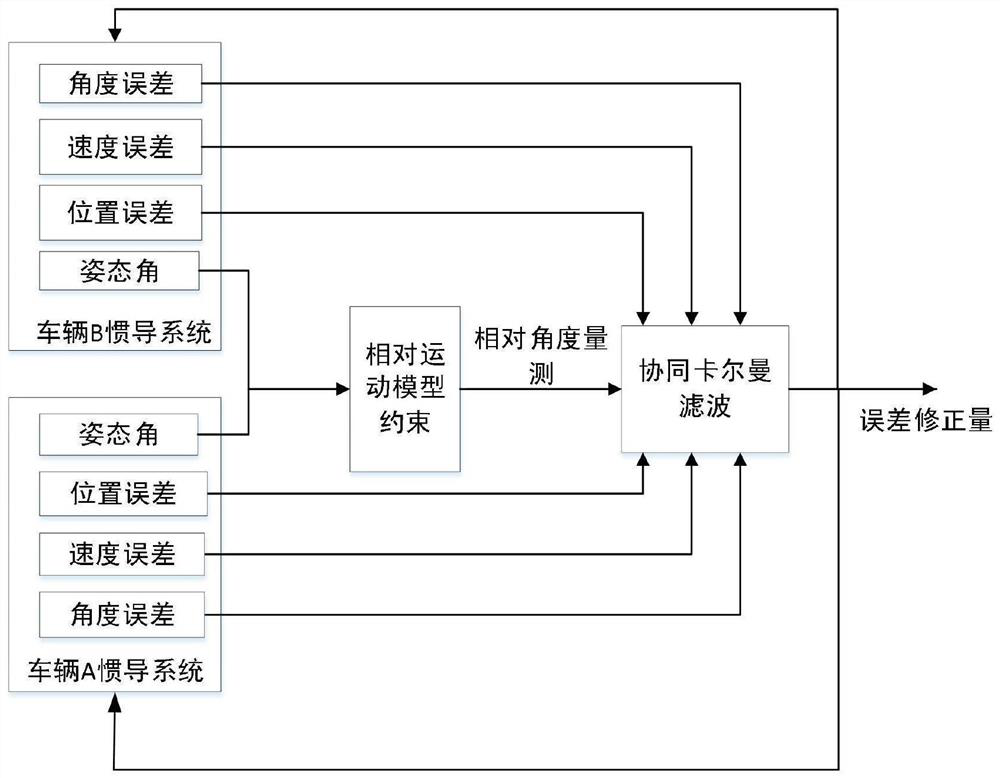

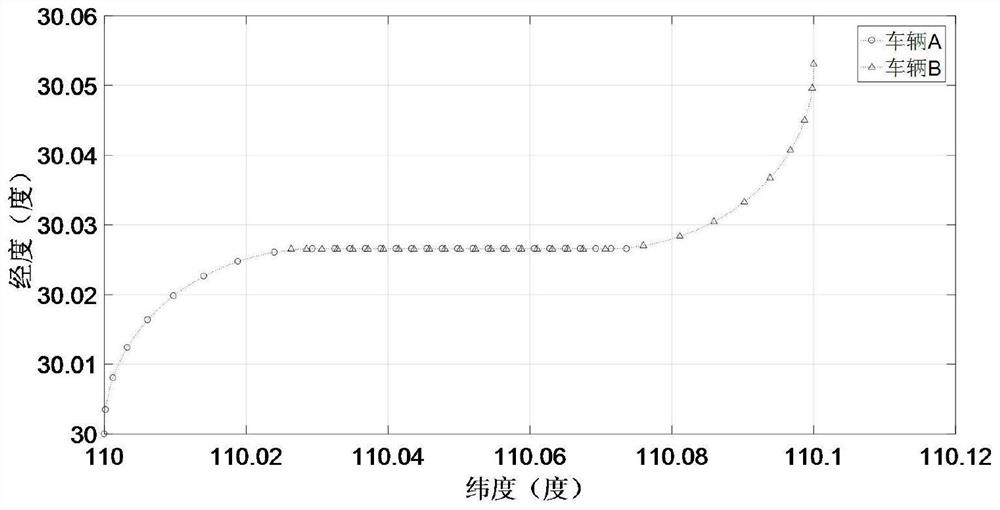

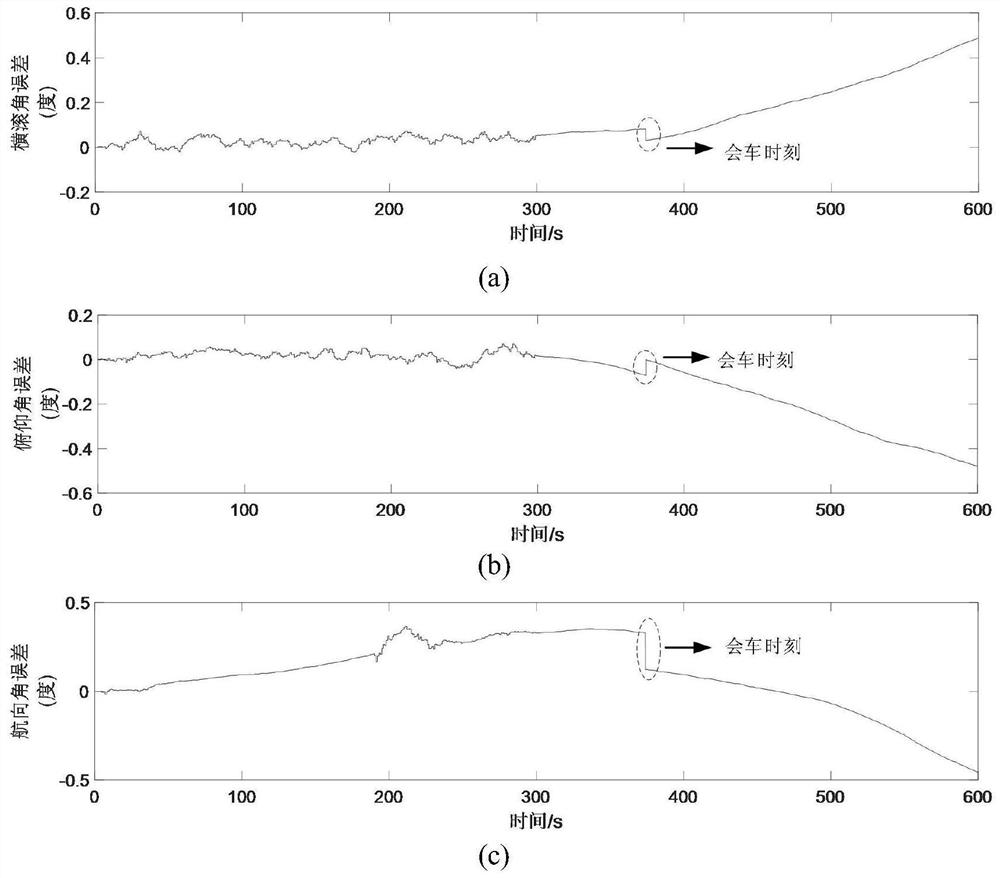

The invention discloses a vehicle cooperative navigation method based on a relative motion model, and belongs to the technical field of vehicle cooperative navigation. The method comprises the following steps: firstly building a state equation of a cooperative navigation system on the basis of an inertial navigation system error equation; then using a Doppler frequency shift effect to calculate frequency deviation, caused by relative motions of vehicles, of a vehicle-mounted wireless radio, and then judging relative meeting time; establishing a vehicle relative motion model and a measurement equation on the basis of the relative motion mode during meeting; finally carrying out discretization on the state equation and the measurement equation, carrying out measurement updating during meeting, and carrying out feedback correction on the state quantity of the system to realize effective amending for the cooperative navigation system. According to the method, relative motion constraint information of vehicles can be utilized effectively in satellite navigation failure environments such as tunnel, effective fusion with inertial navigation is realized, the precision and reliability of the vehicle navigation system are improved, and the method is applicable for engineering application.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

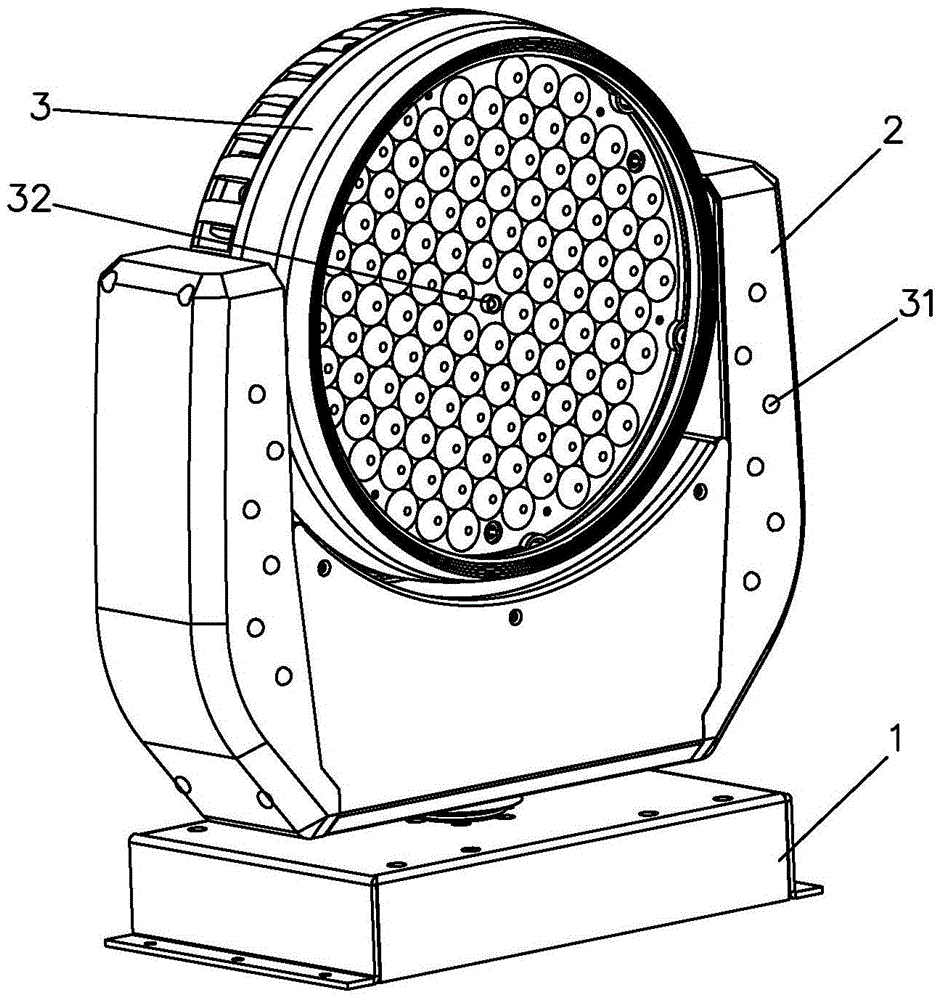

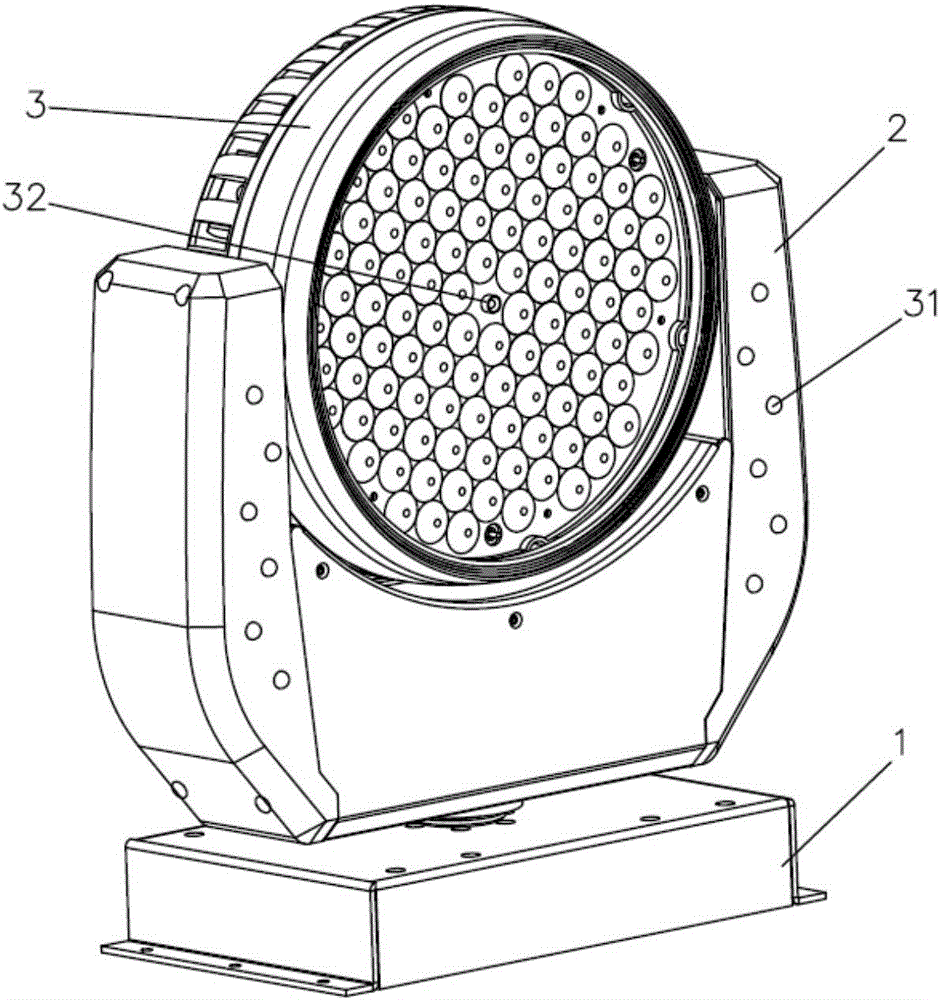

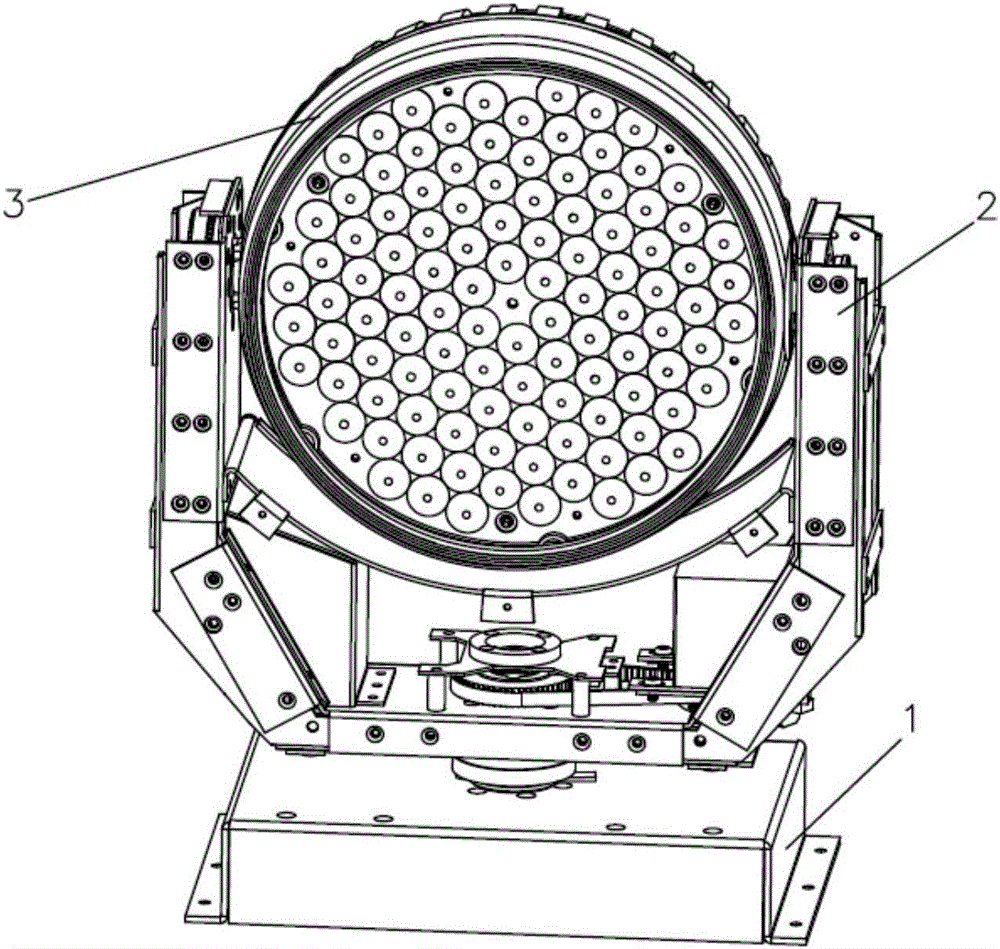

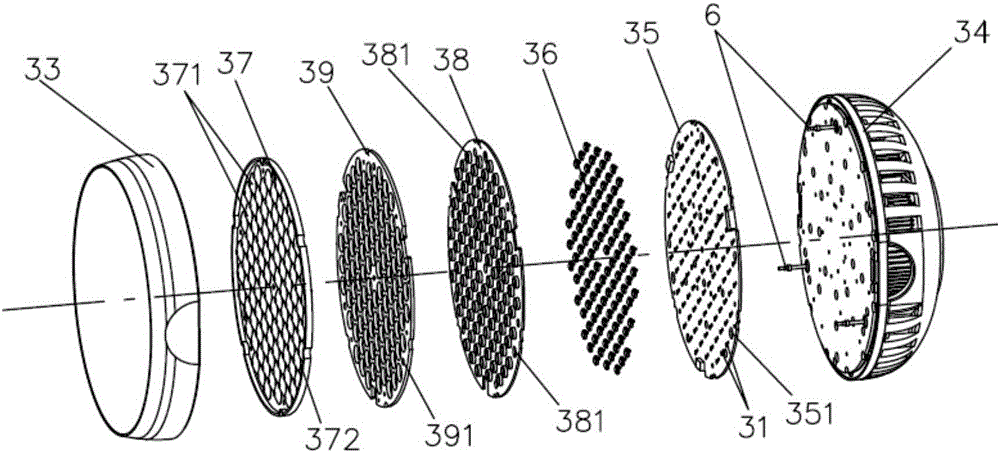

Multi-function vehicle police lamp

ActiveCN104566114AIncrease success rateEasy to useNon-electric lightingLighting support devicesLight beamEngineering

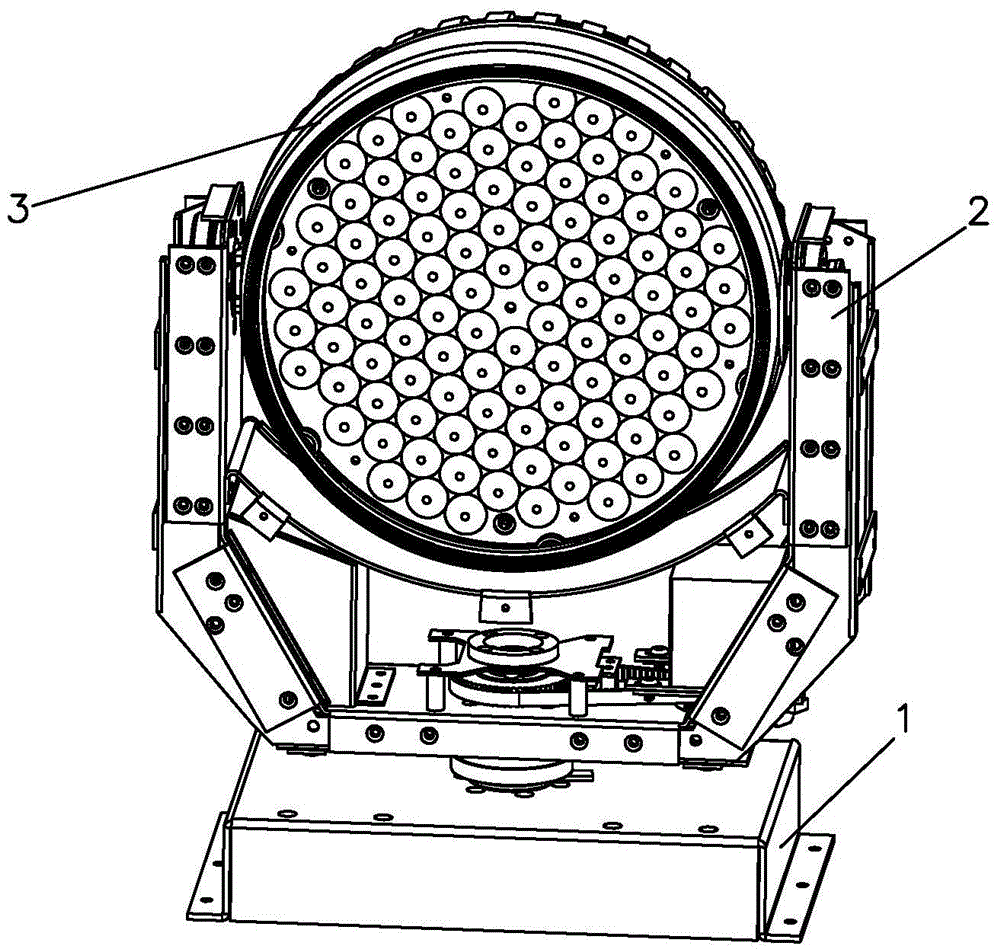

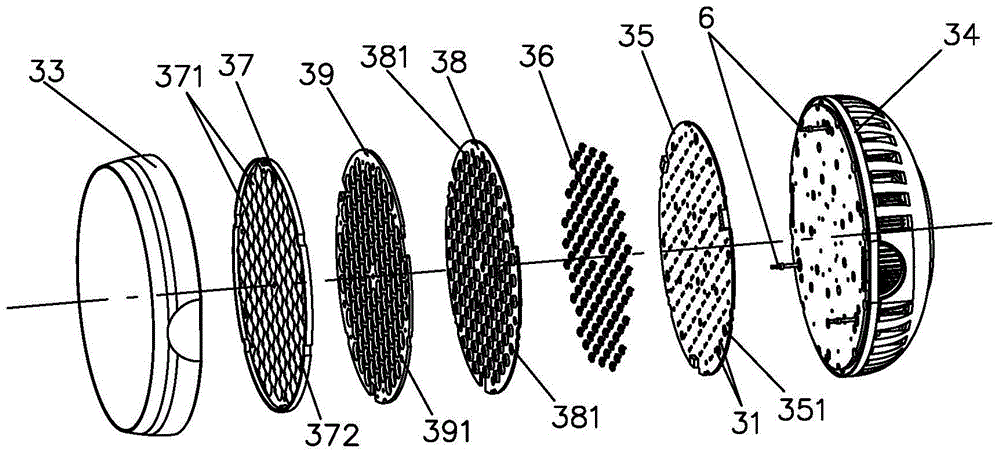

The invention discloses a multi-function vehicle police lamp. The multi-function vehicle police lamp comprises a base, a support, a lamp body, a driving mechanism and a control circuit. The multi-function vehicle police lamp is characterized in that a power output end of the driving mechanism is connected with the support and a power input end of the lamp body to drive the support to rotate and drive the lamp body to swing; LED (Light Emitting Diode) lamp beads and a camera are arranged inside the lamp body; a control output end of the control circuit is connected with the LED lamp beads and an input end of the camera; the LED lamp beads are controlled to emit the light which is irradiated on a target and the camera is controlled by the control circuit through the reflection of the target to perform photographing or video shooting on the target; a single light-emitting color can be adopted by all of the LED lamp beads to form a single-color continuous or flashing light-emitting structure or multiple different light-emitting colors are adopted by the LED lamp beads to form a multi-color continuous or flashing light-emitting structure through arrangement and combination. According to the multi-function vehicle police lamp, light beams can be adjusted, the irradiation range is wide, and the rapid shooting can be achieved.

Owner:广州市德晟光电科技股份有限公司

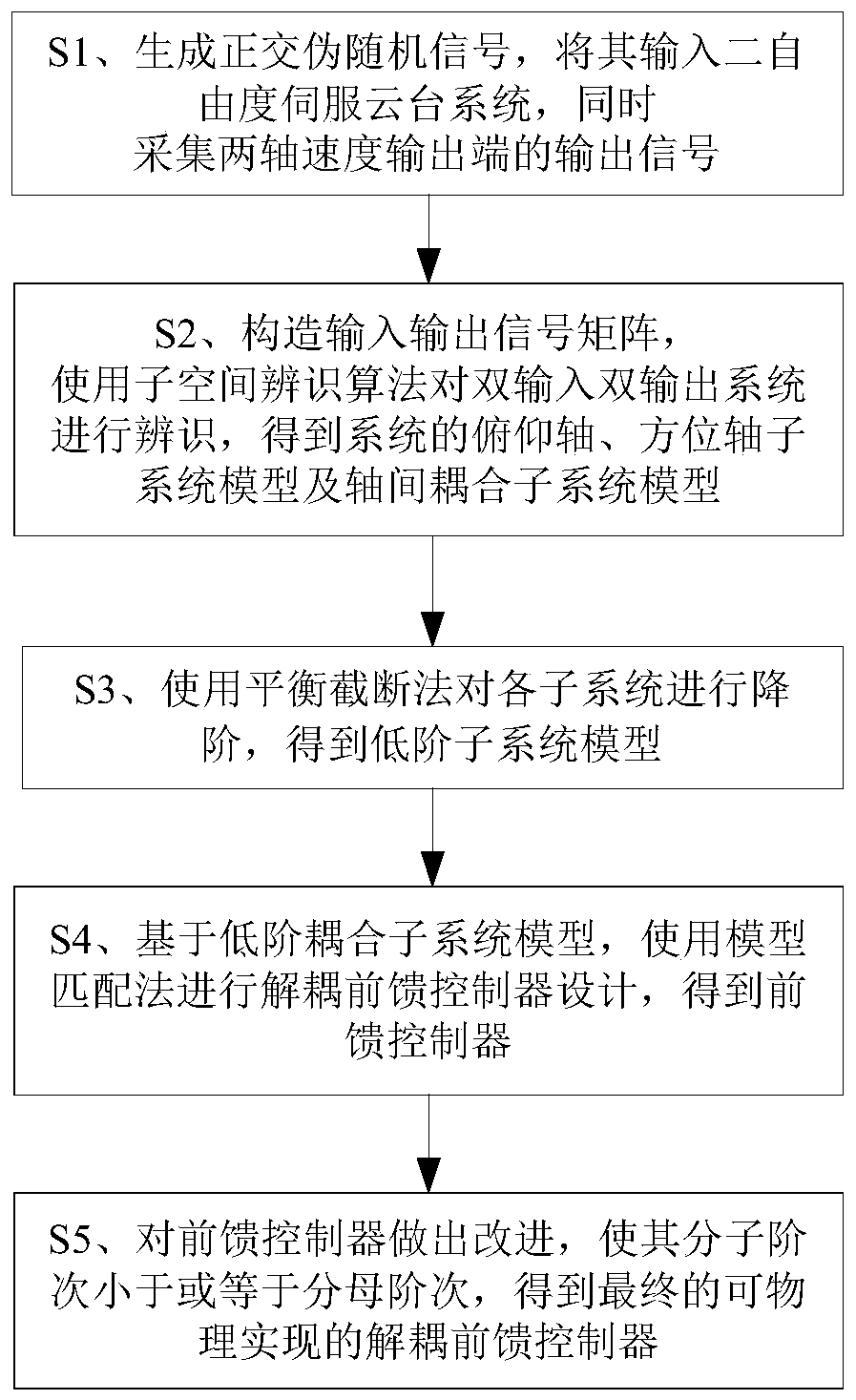

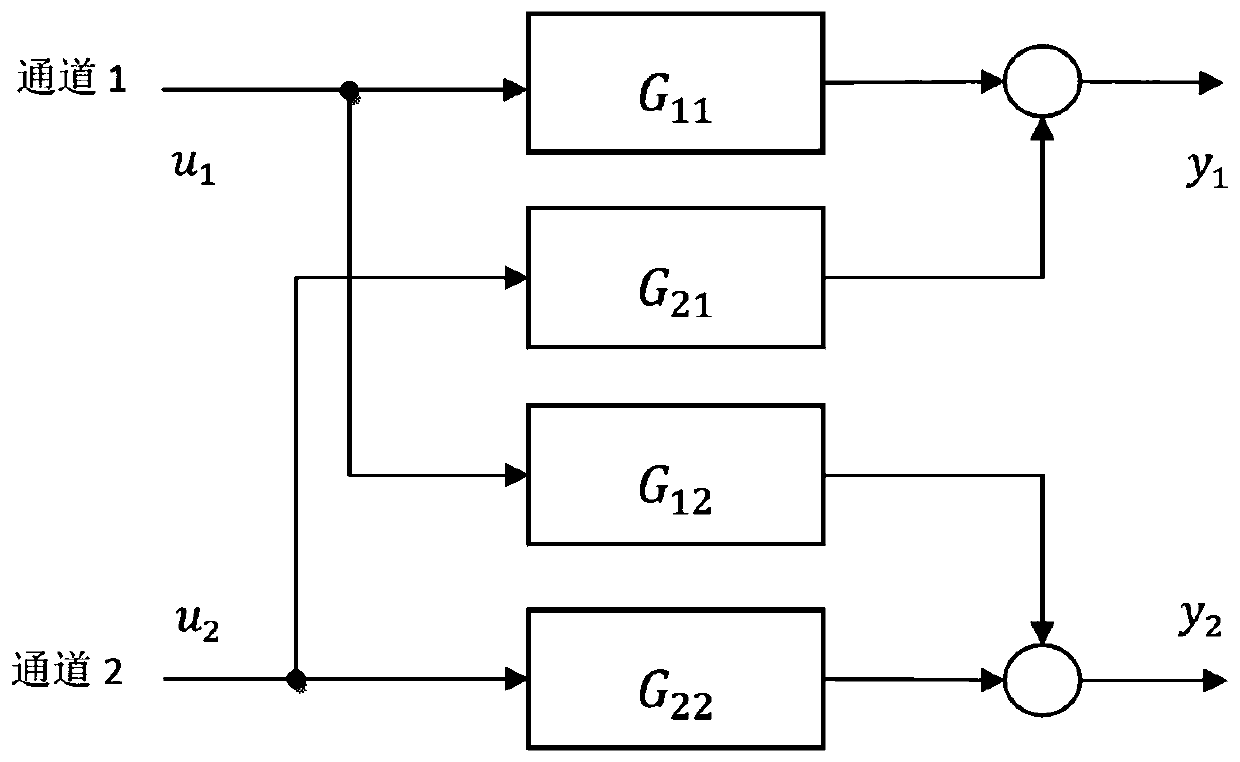

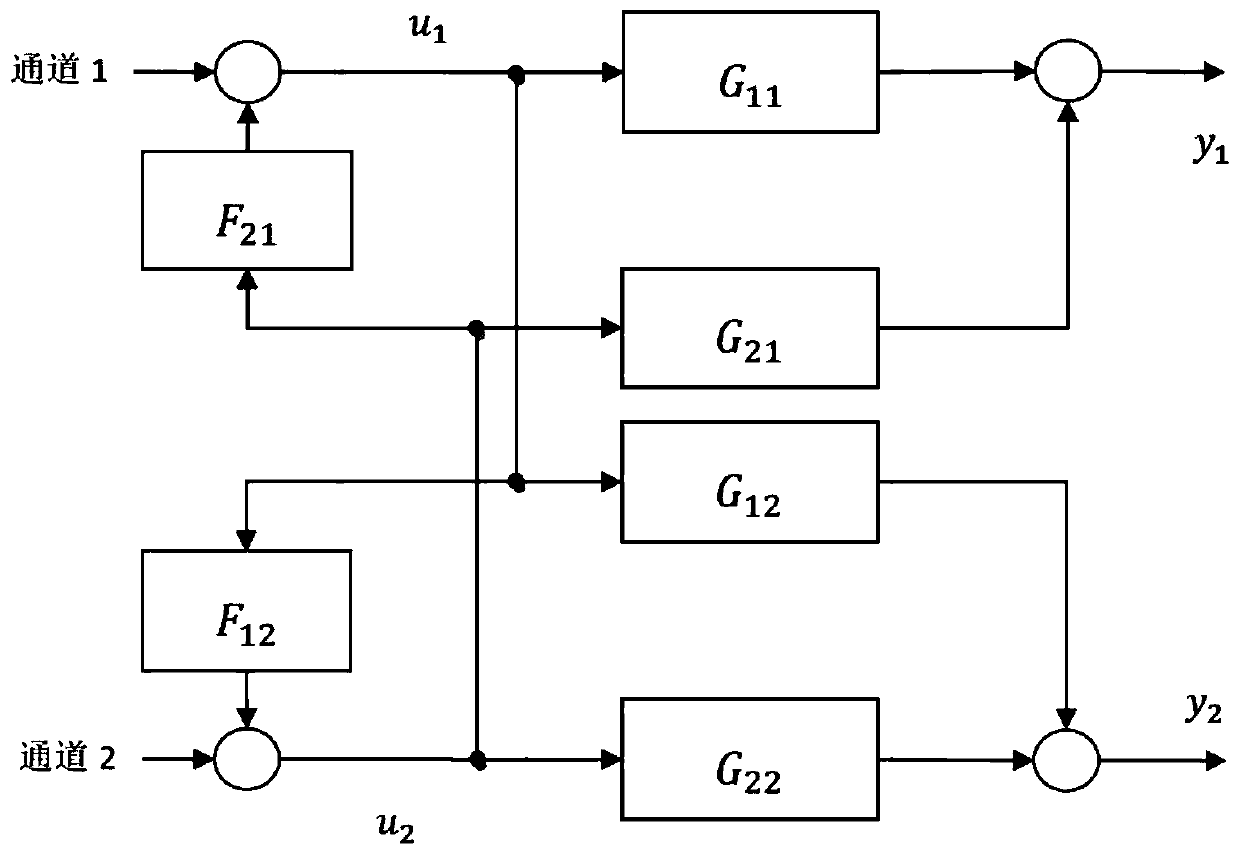

Coupling identification and decoupling control design method of two-degree-of-freedom servo cradle head system

InactiveCN111273553ALow controller orderAchieve stabilizationControl without using feedbackAdaptive controlBalanced truncationOrder reduction

The invention discloses a coupling identification and decoupling control design method for a two-degree-of-freedom servo holder system, and the method comprises the steps: firstly generating an orthogonal pseudo-random signal, inputting the orthogonal pseudo-random signal into the two-degree-of-freedom servo holder system, and collecting an output signal of a two-axis speed output end; constructing an input and output signal matrix, and identifying the two-input and two-output system by using a subspace identification algorithm to obtain a pitch axis subsystem model, an azimuth axis subsystemmodel and an inter-axis coupling subsystem model of the system; performing order reduction on each subsystem by using a balanced truncation method to obtain a low-order subsystem model; based on the low-order coupling subsystem model, carrying out decoupling feedforward controller design by using a model matching method to obtain a feedforward controller; and finally, improving the feedforward controller, so as to enable the molecular order of the feedforward controller to be smaller than or equal to the denominator order, and obtaining the final physically-achievable decoupling feedforward controller. According to the invention, the vibration of the pitch axis of the two-degree-of-freedom servo pan-tilt system caused by inter-axis coupling can be effectively suppressed.

Owner:SOUTH CHINA UNIV OF TECH

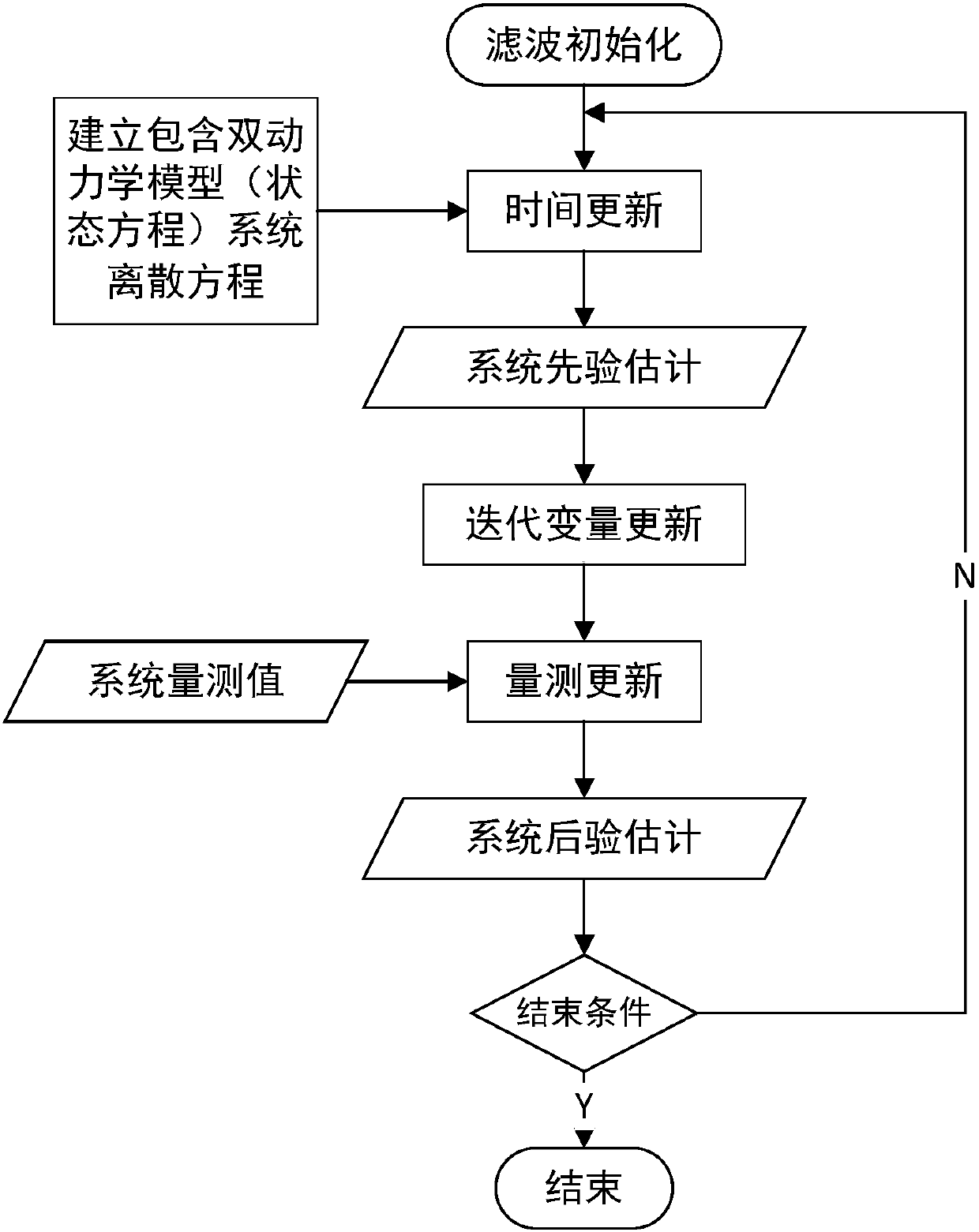

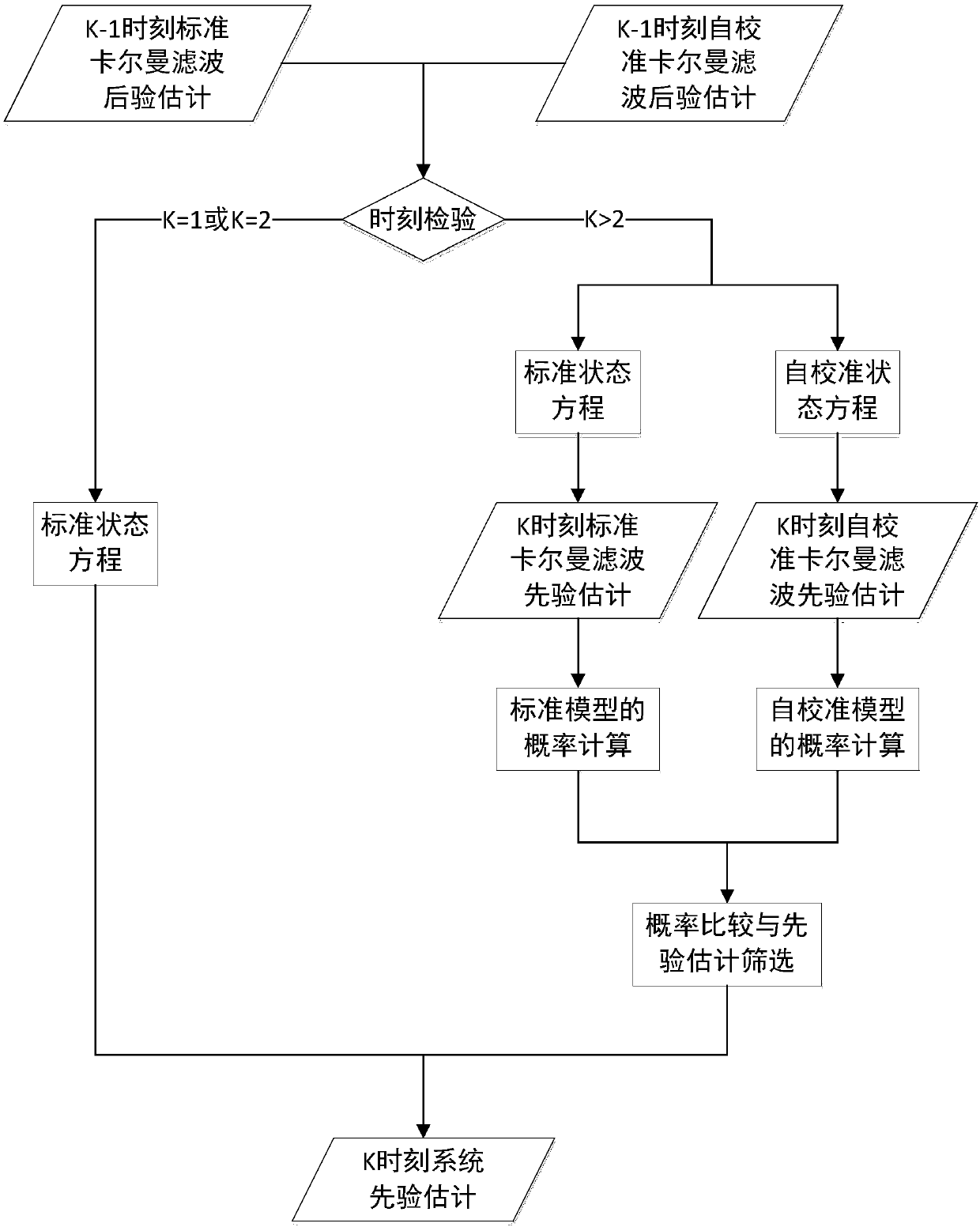

Multiple-model self-calibration Kalman filter (MSKF) method

InactiveCN107632959ASolve the problem of divergenceImprove filtering accuracyCharacter and pattern recognitionComplex mathematical operationsApplicability domainAlgorithm

The invention provides a multiple-model self-calibration Kalman filter (MSKF) method. The method comprises the following steps: 1, establishing system basis equations; 2, carrying out filter initialization on a system consisting of the formula (1), the formula (2) and the formula (3); 3, carrying out time updating on the system; 4, carrying out iterative variable updating; 5, carrying out measurement updating; and 6, carrying out iterative calculation. According to the method, a multiple-model estimation theory is introduced into the problem that system state equations are under unknown inputinterference, and a complete process of the multiple-model self-calibration Kalman filter method is obtained on the basis of a self-calibration Kalman filter and a standard Kalman filter; the problemthat the standard Kalman filter is divergent in filtering in a non-zero segment of unknown input is solved, and filtering precision of the self-calibration Kalman filter in a segment that unknown input is zero is also significantly improved; and filtering precision of the segments that unknown input is or is not zero is improved at the same time, an applicable range is further expanded, and systemrobustness is also further improved on the basis of a self-calibration Kalman filter method (SKF).

Owner:BEIHANG UNIV

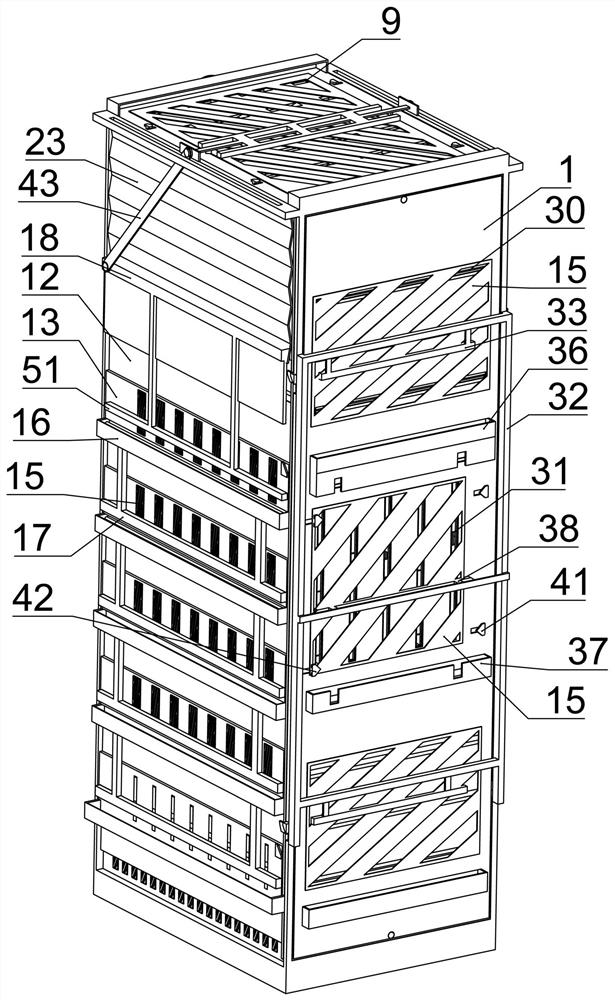

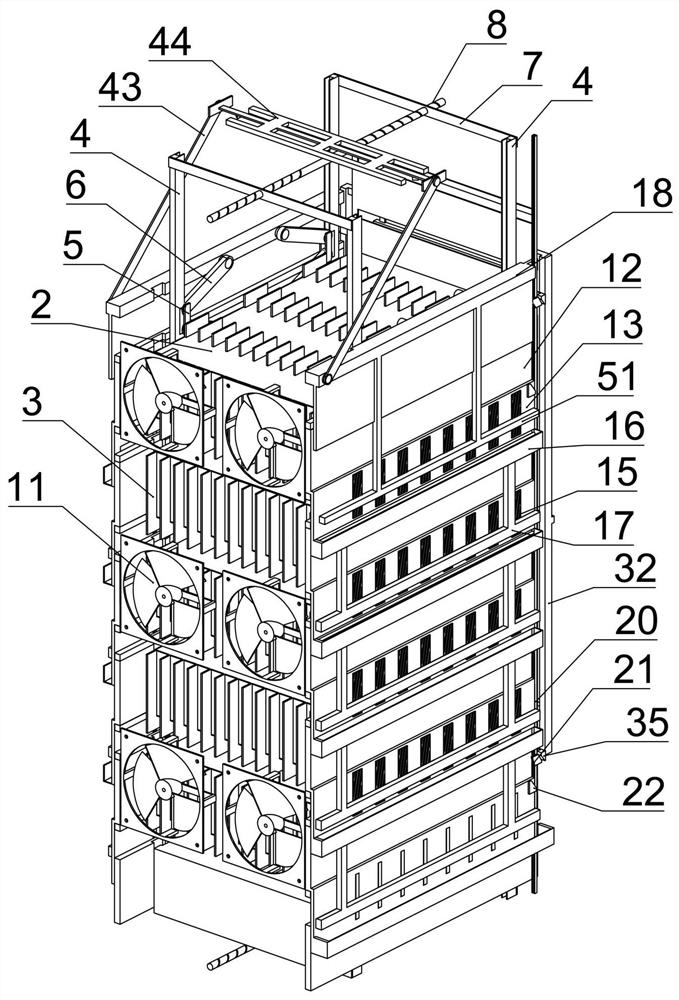

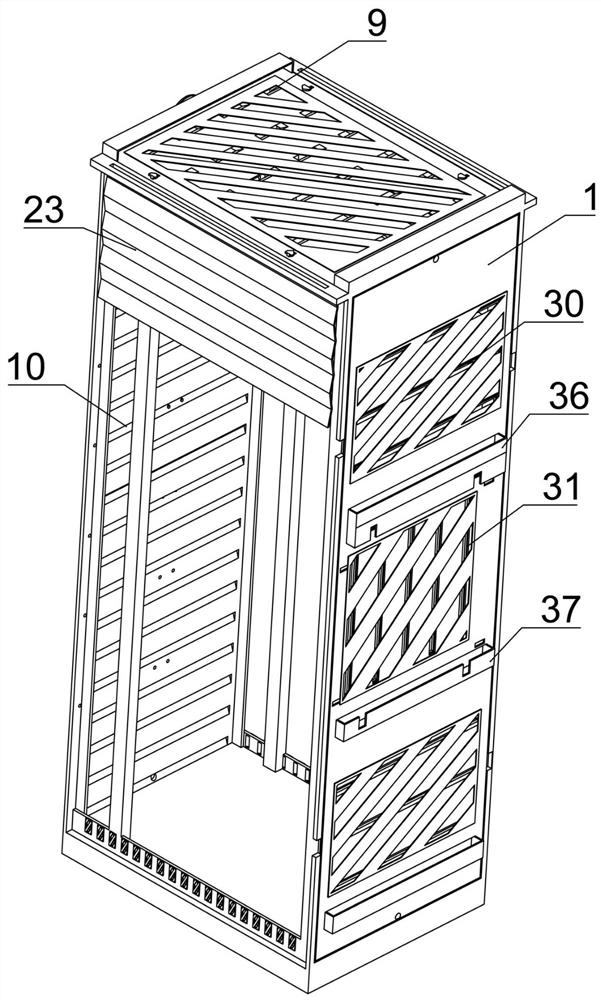

Computer big data server heat dissipation device

ActiveCN112506328ASolve the impactSolve the problem of divergenceFouling preventionDigital data processing detailsEngineeringMechanical engineering

The invention discloses a computer big data server heat dissipation device and effectively solves the problem that an existing device is poor in heat dissipation effect. According to the specific solution, the server cooling device comprises a cabinet, a plurality of server cooling frames arranged up and down are connected in the cabinet in an up-down sliding mode, a front cooling control rod anda rear cooling control rod are connected to the left side wall and the right side wall in the cabinet in a front-back sliding mode, and a plurality of limiting connecting pieces are connected to the cooling control rods in an up-down sliding mode; an upper supporting control connecting rod and a lower supporting control connecting rod are rotationally connected to all the limiting connecting pieces, the other ends of the two supporting control connecting rods are rotationally connected with the upper server heat dissipation frame and the lower server heat dissipation frame respectively, and the upper end and the lower end of each heat dissipation control rod are fixedly connected through a transverse fixing plate which is in threaded connection with a bidirectional threaded rod rotationally connected with the cabinet. Air inlets are formed in the top end and the lower end of the cabinet, air outlets are formed in the rear end face of the cabinet, and multiple sets of air draft motors are fixedly connected to the rear end face in the cabinet. The invention can solve the problem that heat dissipation is affected by dust in the server to a great extent.

Owner:ZHENGZHOU UNIV OF IND TECH

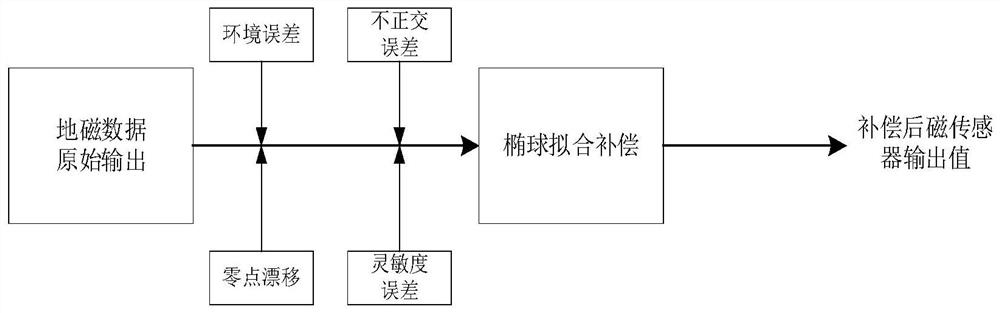

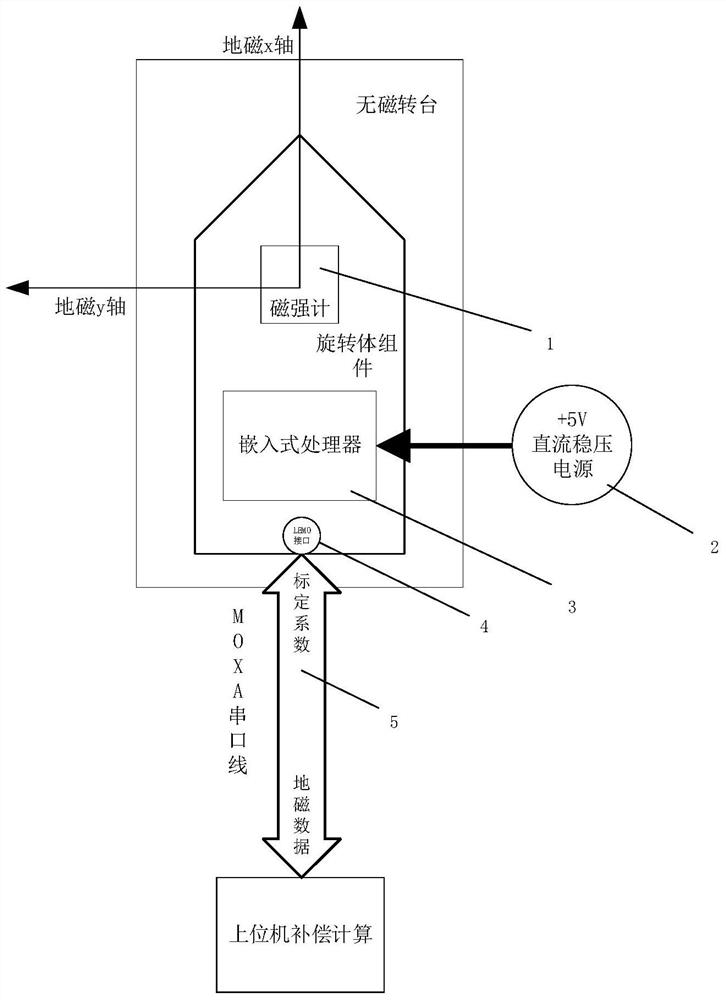

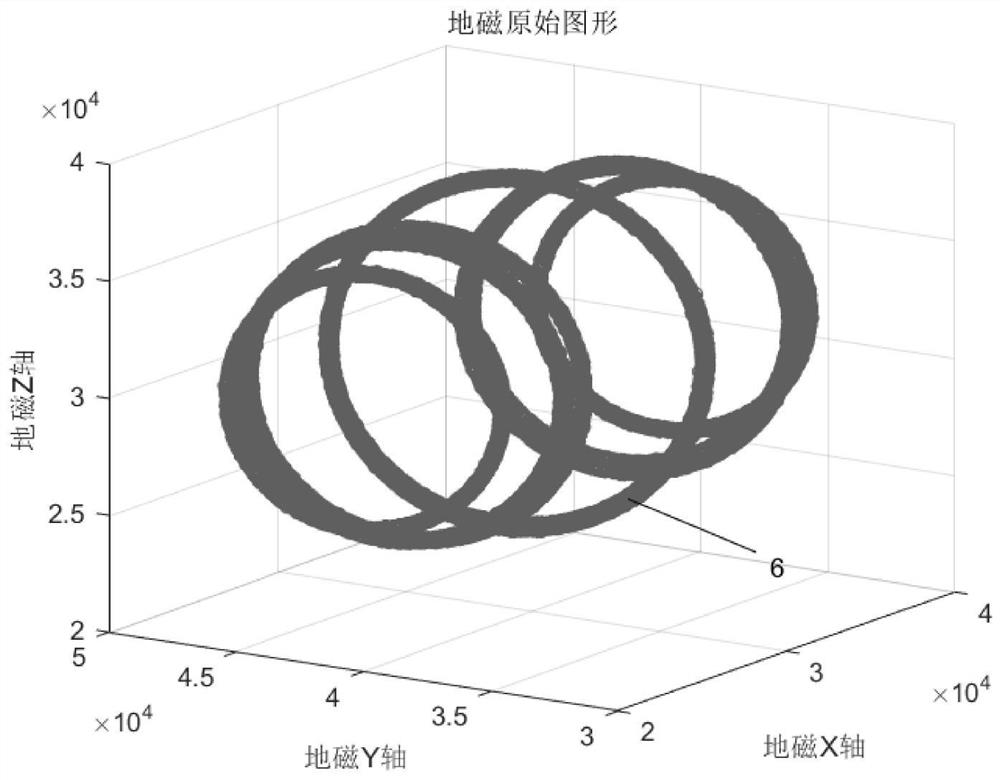

Rotating body error compensation and experiment method for three-axis magnetic sensor

InactiveCN113624253ASolve the problem of divergenceGuaranteed accuracyMeasurement devicesComputational physicsMechanical engineering

The invention discloses a rotating body error compensation and experiment method for a three-axis magnetic sensor. According to the actual environment where a rotating body is located, an error source is analyzed, and an error model containing temperature and environment influences is established; the environment error of the rotating body is compensated through ellipsoid fitting; and compensation verification is performed on the actual geomagnetic sensor by adopting a non-magnetic turntable and a plane rotation point acquisition method. According to the invention, the influence of the environmental magnetic field and the installation position on the output of the sensor is effectively solved, and the error calibration of the rotating body of the three-axis magnetic sensor under the interference of the magnetic environment can be realized.

Owner:NANJING UNIV OF SCI & TECH

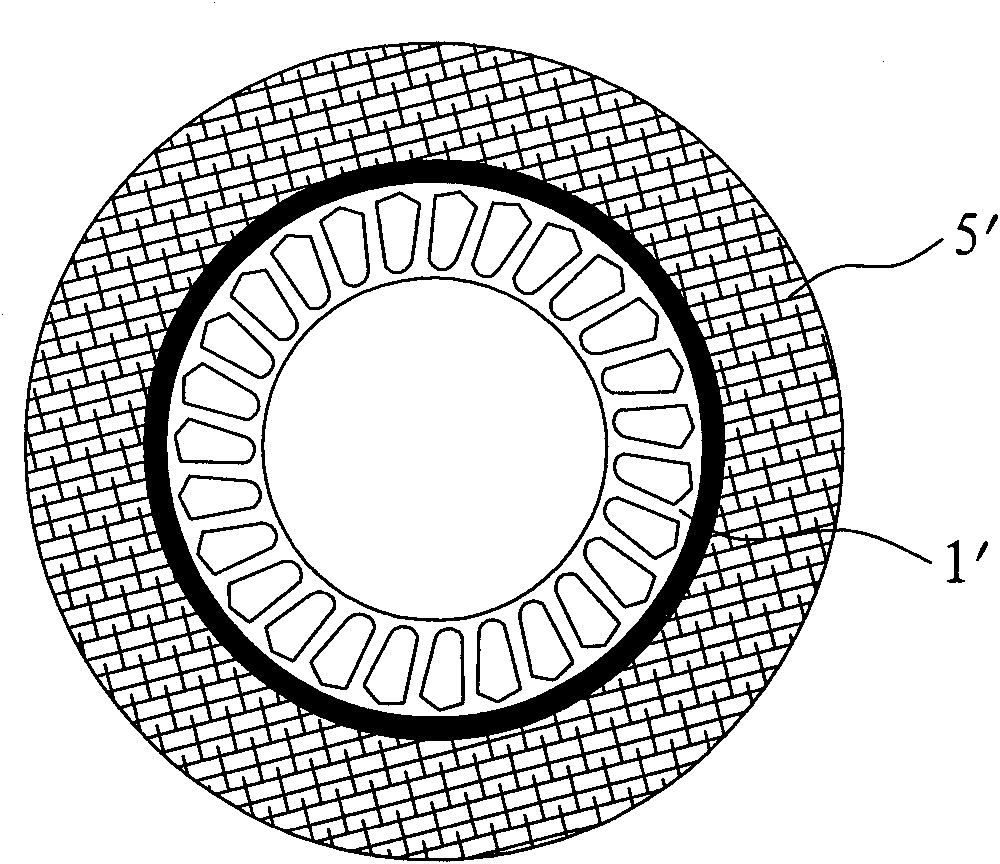

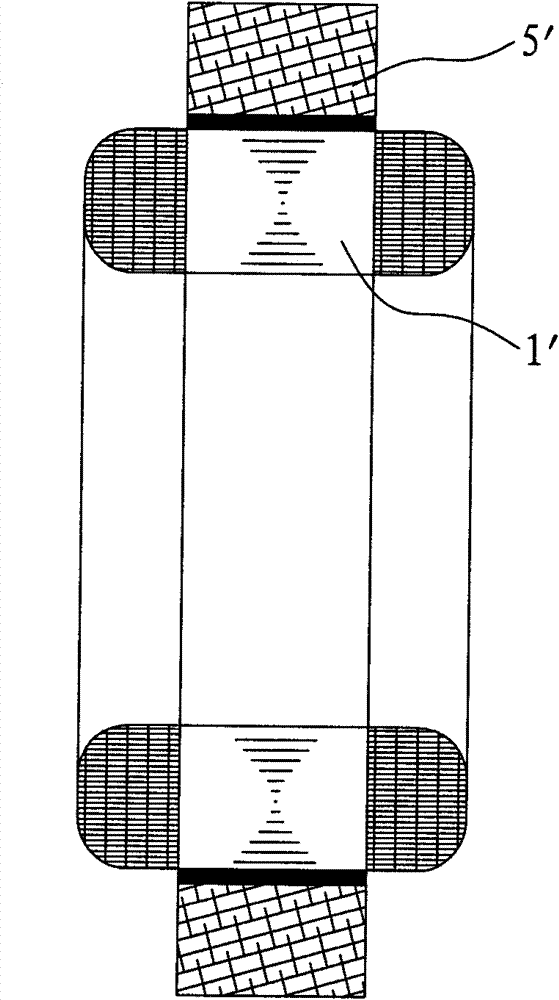

Spliced stator iron core of tractor

ActiveCN102088229BReduce iron lossImprove work performanceSynchronous machine detailsMagnetic circuit stationary partsWork performanceStator coil

The invention discloses a spliced stator iron core of a tractor. The stator iron core consists of a plurality of separated stator blocks, wherein each separated stator block is formed by laminating a plurality of blocks of separated stator stamped sheets with the same structure; a winding groove winding a stator coil is formed on each of the separated stator stamped sheets; and the plurality of separated stator blocks fix the plurality of separated stator blocks through pressing rings to form the annular stator iron core with a certain thickness. The invention provides a combined stator iron core. In the invention, the stator iron core of a lifter tractor is modified into a separated structure from an integrated structure, namely a tractor stator winding is divided into a plurality of separated stator iron cores, and the plurality of separated stator iron cores are combined into one through a reliable structure, so that the material utilization rate of the stator winding, the working performance of the tractor and the power output of the tractor are greatly improved.

Owner:XJ SCHINDLER XUCHANG ELEVATOR +1

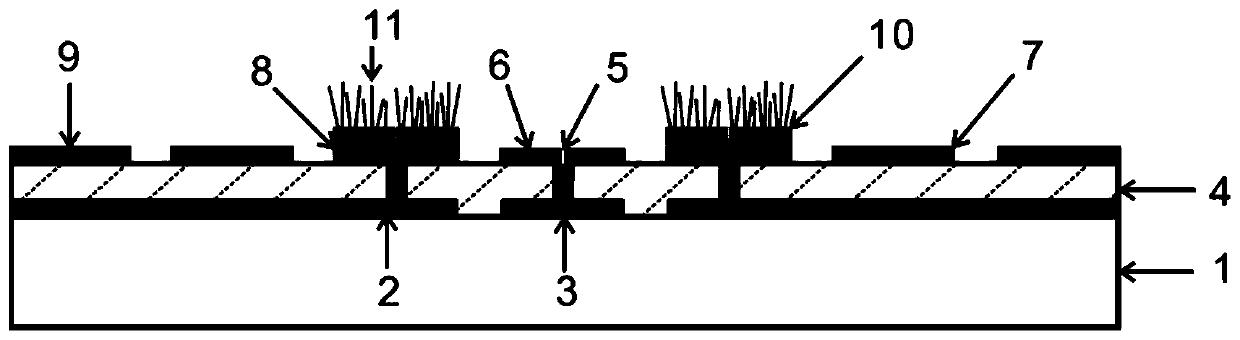

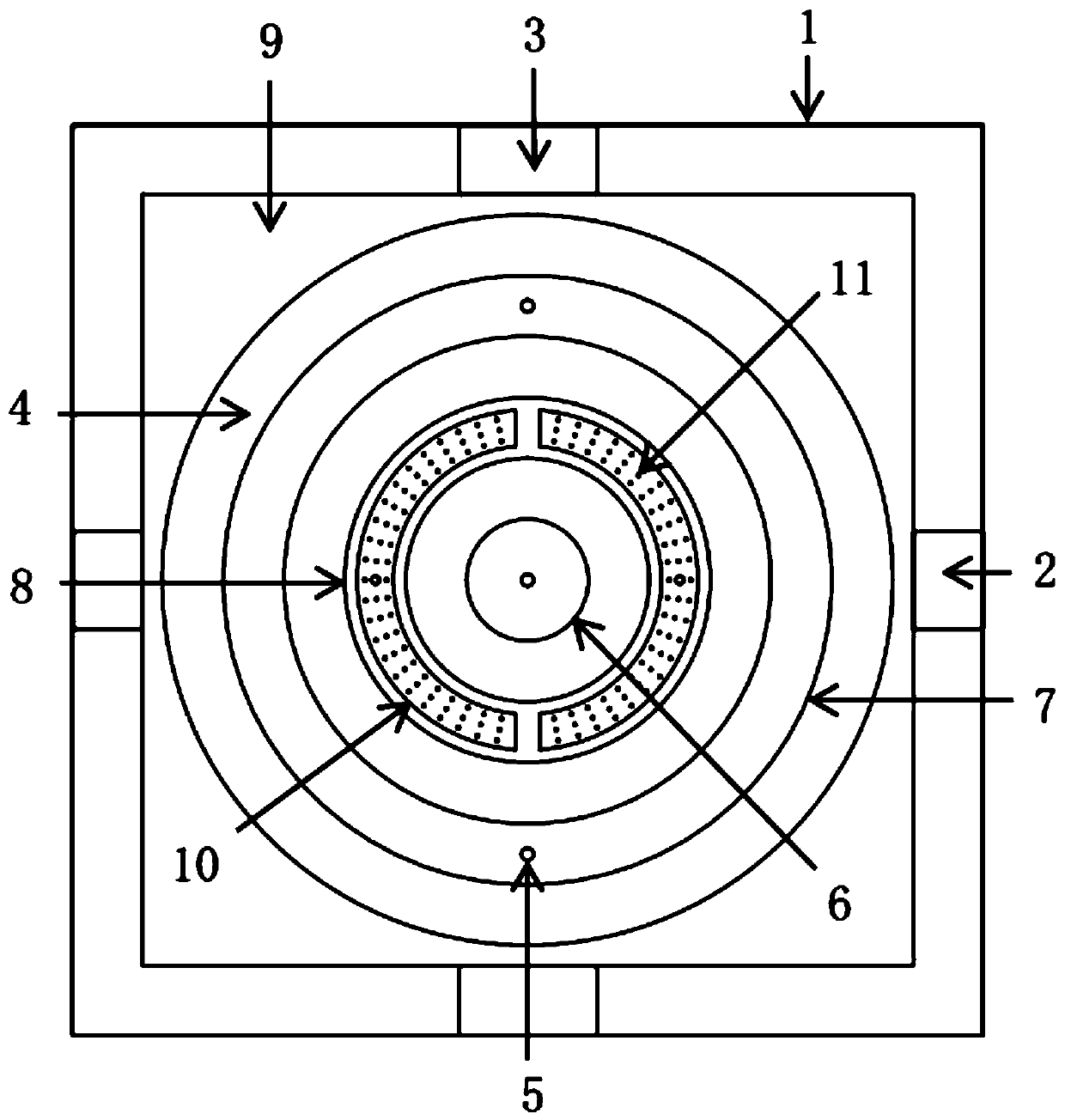

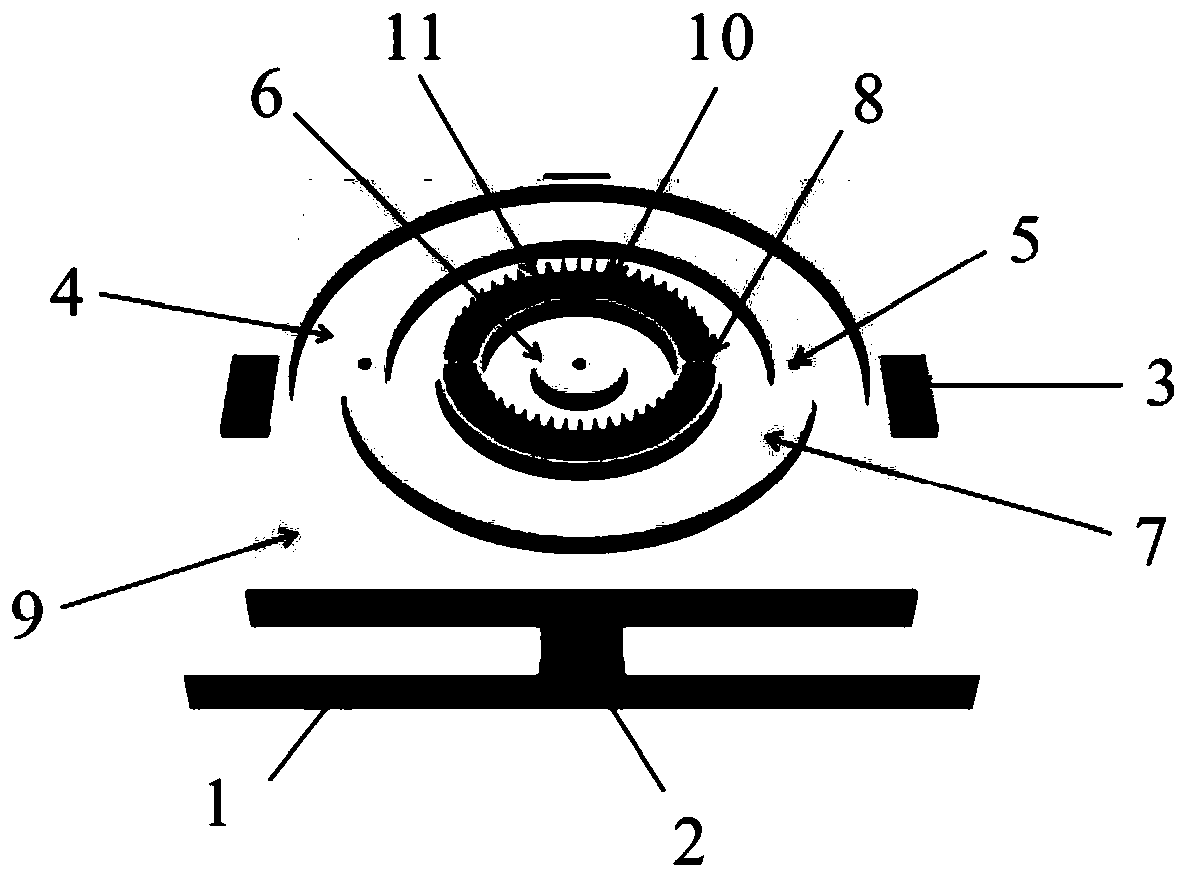

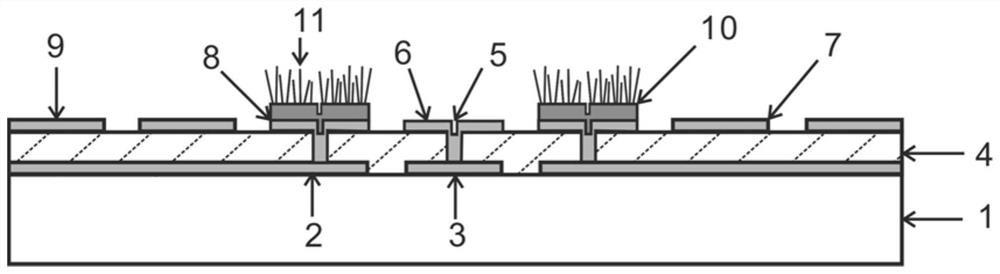

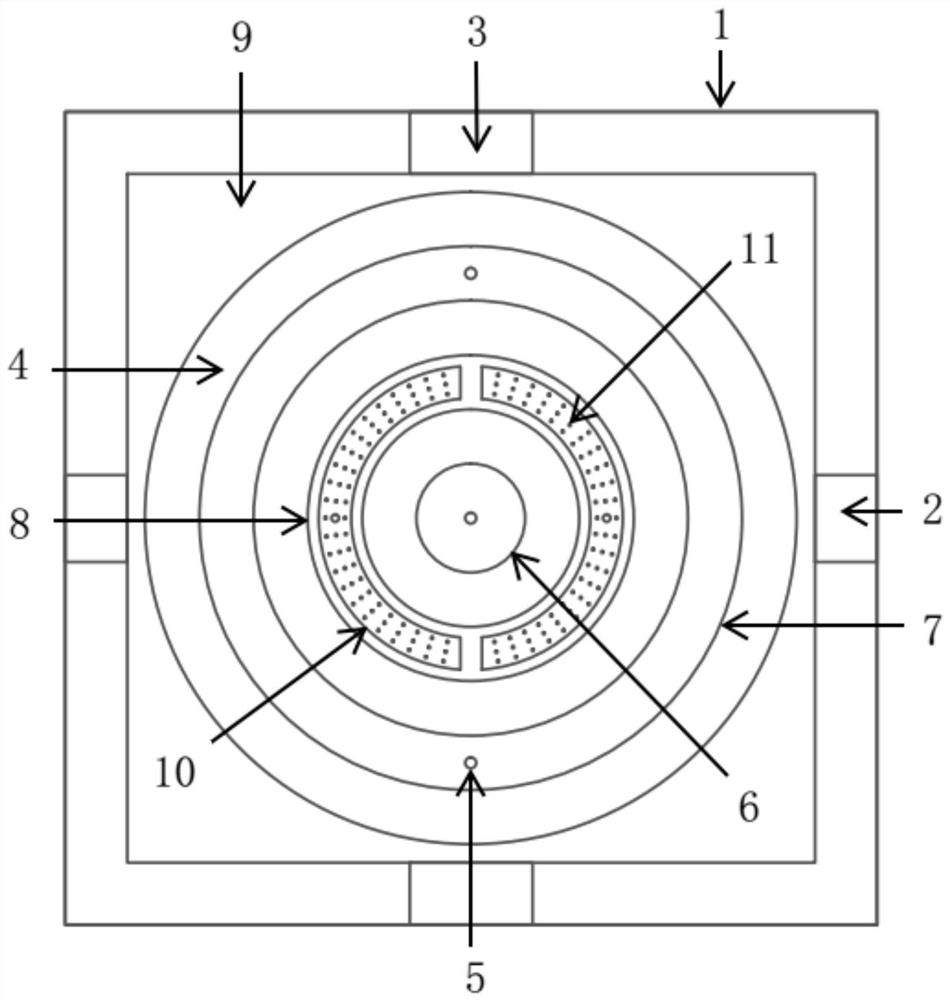

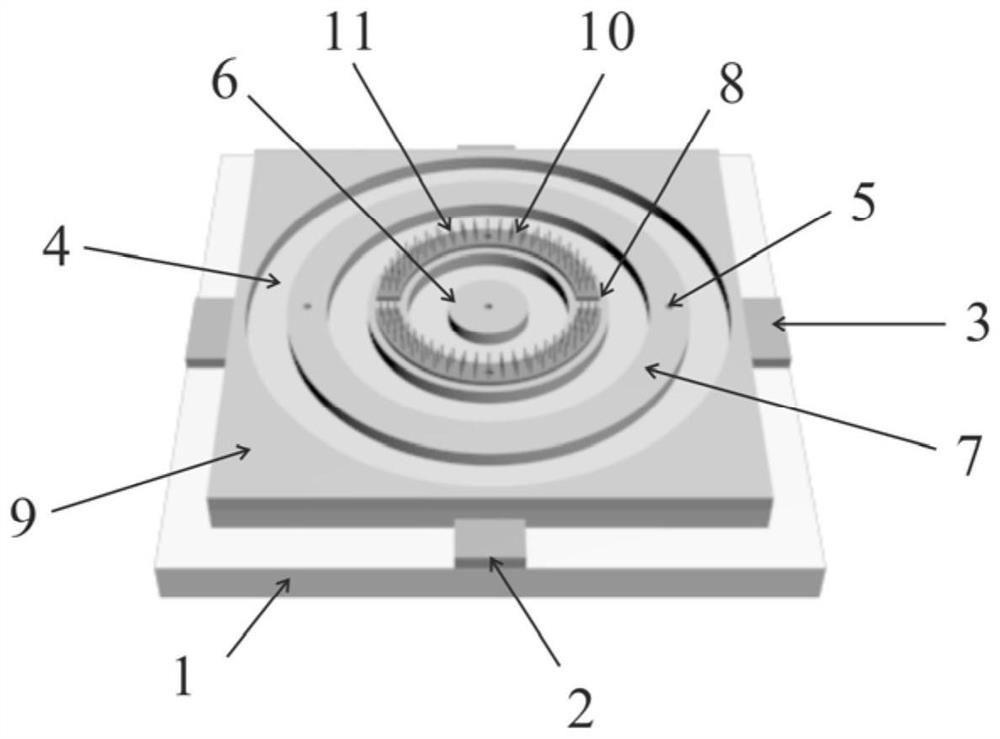

Nanometer cold cathode electron source of coplanar double-gate focusing structure and manufacturing method of nanometer cold cathode electron source

ActiveCN111081505AHigh field emission currentImprove gate control characteristicsDischarge tube main electrodesCold cathode manufactureNanowireEtching

The invention discloses a nanometer cold cathode electron source of a coplanar double-gate focusing structure, which comprises a substrate, an insulating layer, a bottom-layer segmented cathode electrode, a bottom-layer gate electrode, an etching through hole, a top-layer annular cathode electrode, a top-layer internal gate electrode, a top-layer external annular gate electrode, a growth source thin film, a nanowire cold cathode and a focusing electrode, wherein the top-layer internal gate electrode and the top-layer external annular gate electrode are connected with the bottom-layer gate electrode through the etching through hole, and the top-layer annular cathode electrode is connected with the bottom-layer segmented cathode electrode through the etching through hole. The invention further discloses a preparation method of the nanometer cold cathode electron source of the coplanar double-gate focusing structure. The nanometer cold cathode electron source has strong gate-control electron emission capability and electron beam focusing capability and has a coplanar double-gate focusing structure capable of row and column addressing.

Owner:SUN YAT SEN UNIV

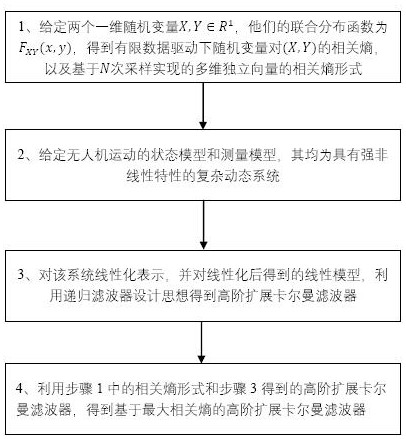

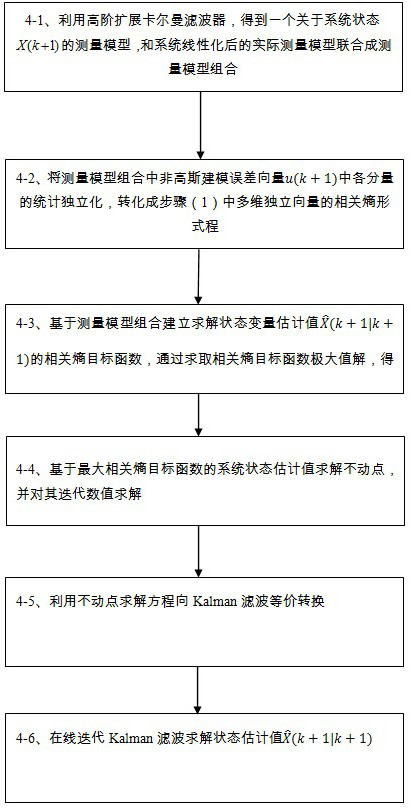

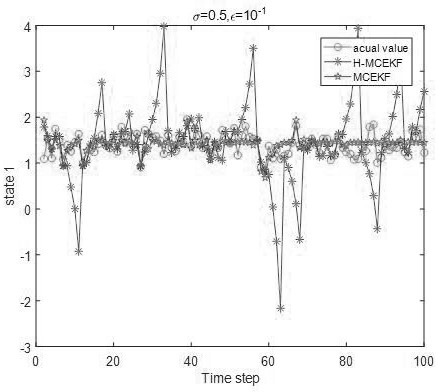

High-order extended Kalman filter design method based on maximum correlation entropy

PendingCN113032988ASolve the degradation of filtering performanceSolve the problem of divergenceDesign optimisation/simulationComplex mathematical operationsAlgorithmIndependent vector

The invention discloses a high-order extended Kalman filter design method based on maximum correlation entropy. According to the method, the method comprises the steps: two one-dimensional random variables are given, and the correlation entropy of a random variable pair under limited data driving is obtained; then a state model and a measurement model of the motion of the unmanned aerial vehicle are given; a high-order polynomial in a state model is defined as a hidden variable of a system, the state model of the system is represented in a pseudo-linearization mode, a measurement model is represented in a pseudo-linearization mode in the same way, and linear forms of the state model and the measurement model are obtained; for the state model and the measurement model in the linear form, a high-order extended Kalman filter is obtained by using a recursive filter design thought; and the high-order extended Kalman filter based on the maximum correlation entropy is designed by using the correlation entropy form of the multi-dimensional independent vector and the obtained high-order extended Kalman filter. According to the method, the problems of reduction and divergence of filtering performance under the condition of a nonlinear non-Gaussian system can be solved, and the method can be applied to the fields of real-time estimation and target tracking.

Owner:HANGZHOU DIANZI UNIV

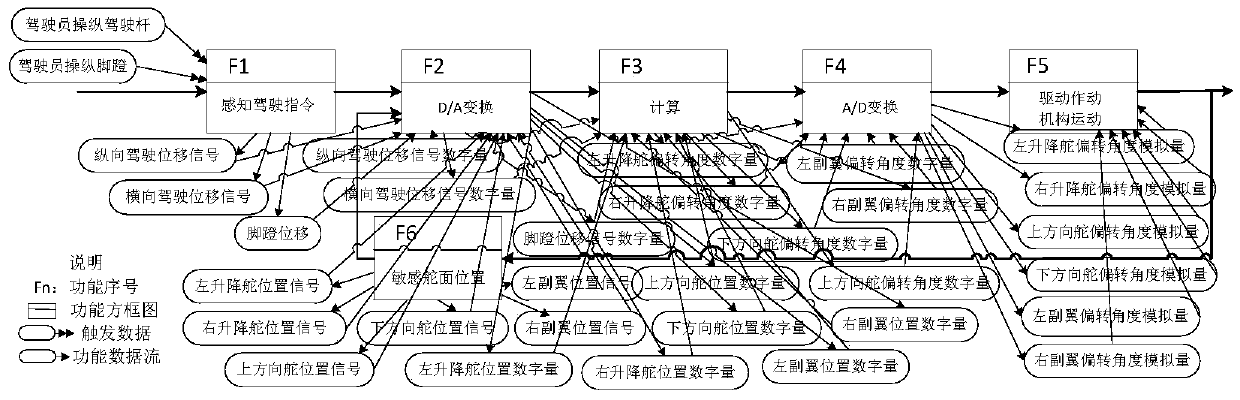

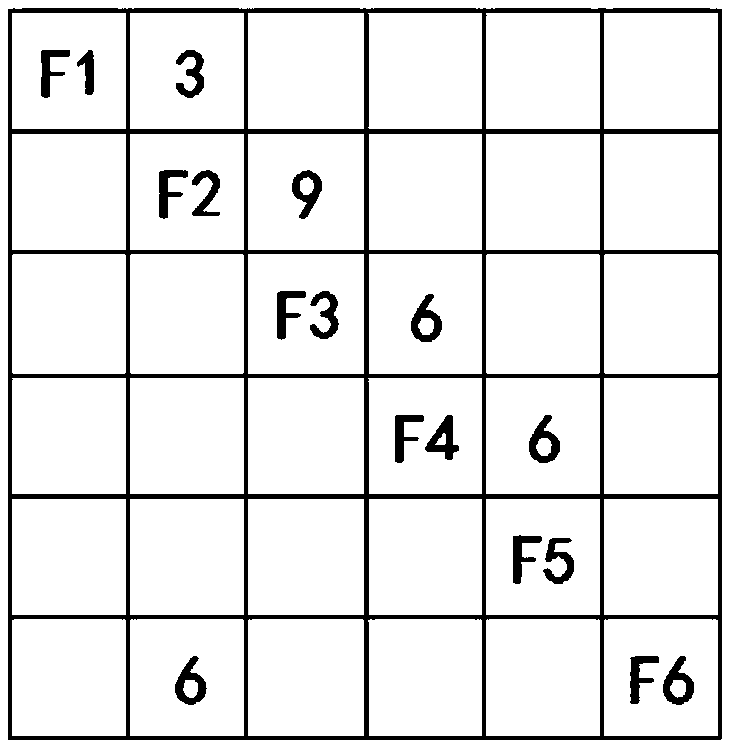

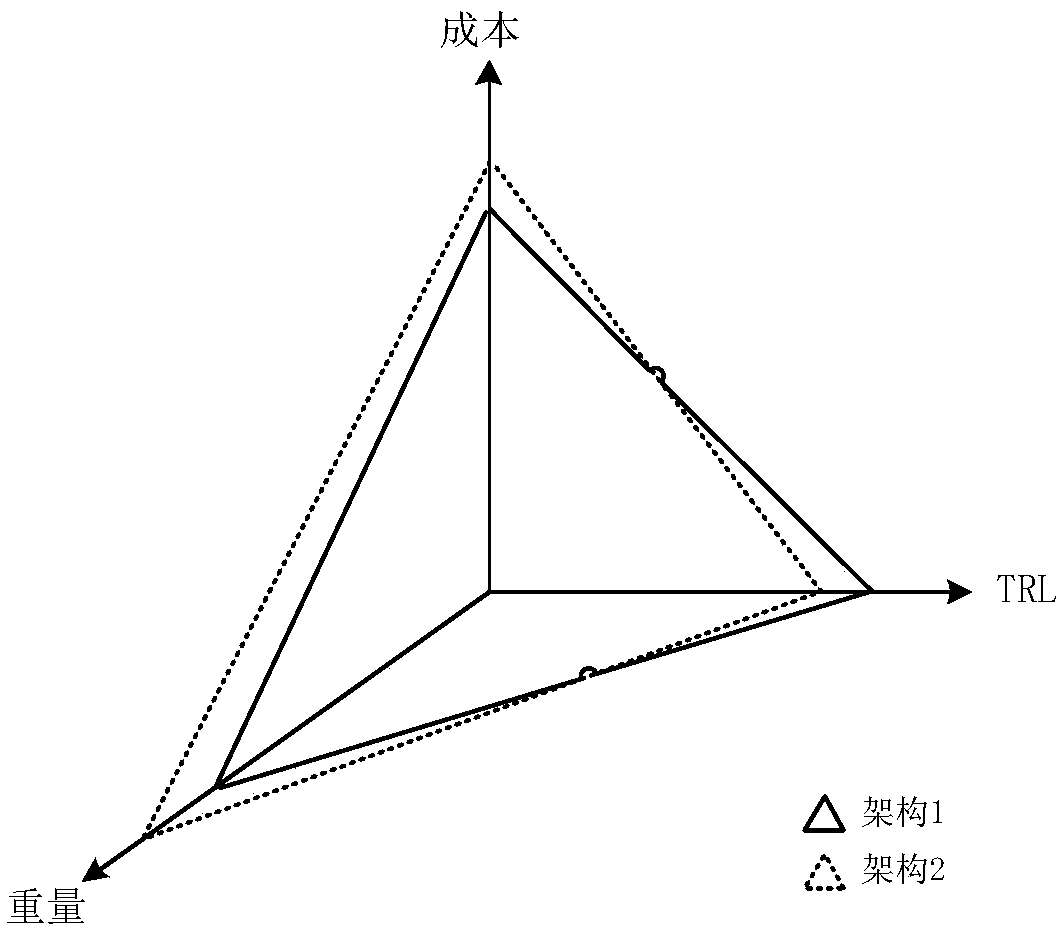

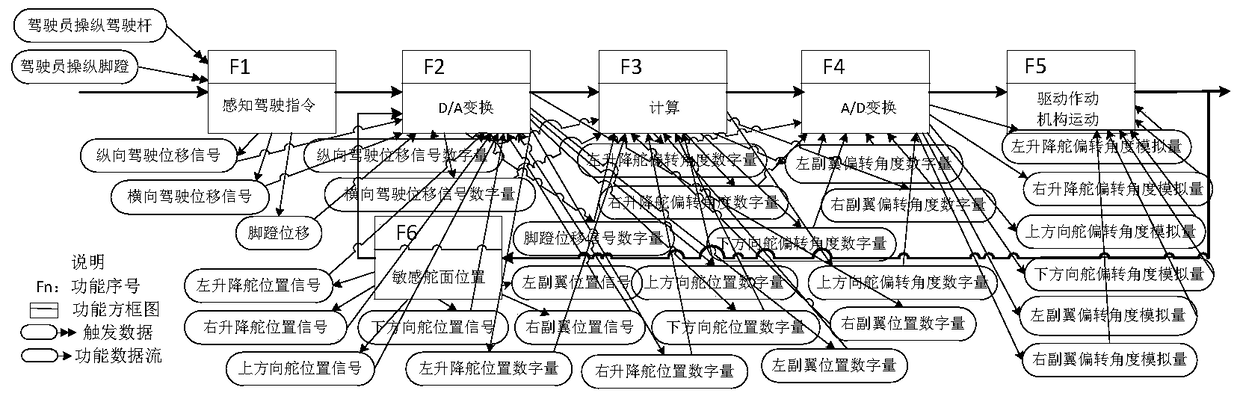

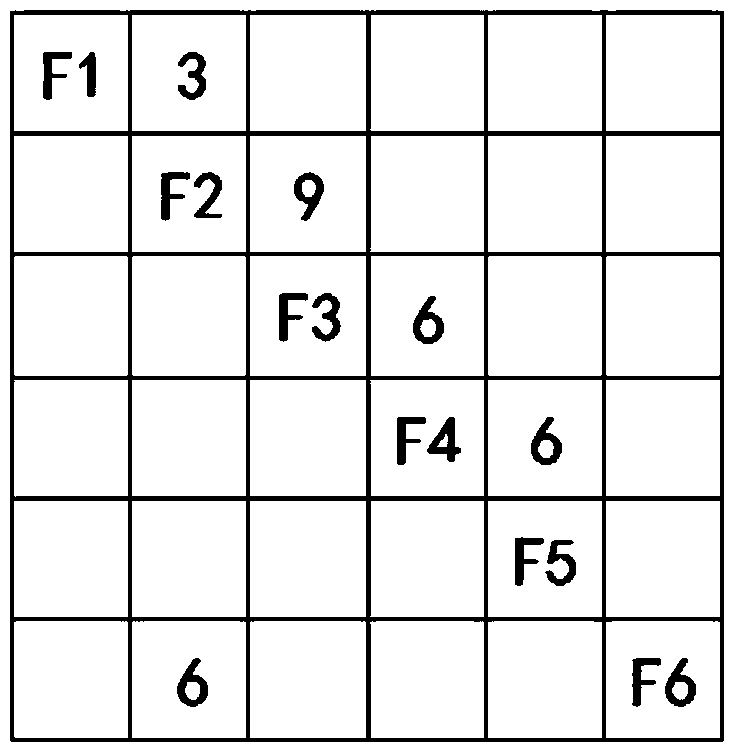

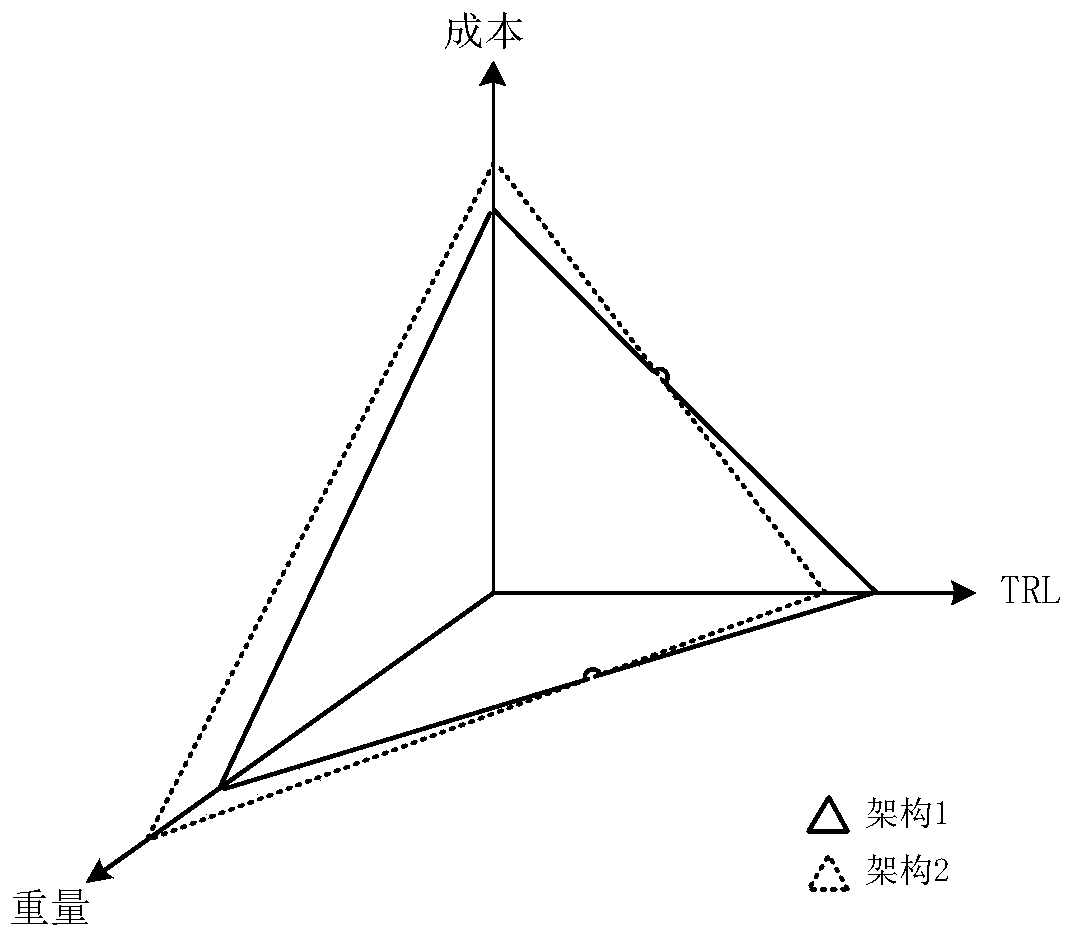

System architecture construction method

ActiveCN105512403APerfect methodologySolve the problem of divergenceConstraint-based CADSpecial data processing applicationsData streamComputer architecture

The invention discloses a system architecture construction method and belongs to the field of system engineering. On the basis of an N2 diagram of a system architecture, an architecture allocation sheet is constructed, the allocation condition of multiple physical devices in any architecture scheme is represented, then all physical interface relations of the physical devices in the architecture allocation sheet when the physical device realizes corresponding functions are listed, and a second N2 diagram with physical interface relations is constructed according to the physical interface relations; finally, multiple architecture schemes with the physical interface relation similarity up to the threshold under different architecture schemes are found out from the second N2 diagram, the same physical device with different indexes under the multiple architecture schemes is found out from the architecture allocation sheet, a spider diagram of the physical device is constructed, and the optimal system architecture scheme is selected according to the spider diagram. With the adoption of the method, the functional requirement of the system is unfolded in a hierarchy form, ordinal relations and data streams among functions are displayed, and the optimal architecture scheme can be selected.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Method for heating screw cylinder of spinning machine and device thereof

ActiveCN101588657BSolve the problem of divergenceThere will be no phenomena such as aging and disconnectionCoil arrangementsArtificial thread manufacturing machinesInsulation layerMetallic materials

The method for heating a screw cylinder of a spinning machine, designed by the invention, specifically comprises that: for the screws equal to [phi]105 millimeters and below [phi]105 millimeters, electromagnetic heating is implemented in each heating region by using 220V power source; three-phase four-wire 380V power source is utilized to power apparatus above [phi]105 millimeters, and 2-4 electromagnetic heating coils are utilized to heat in each hearing region; an electromagnetic controller rectifies alternating current to direct current and converts the direct current into high-frequency current having frequency of 20-40kHz; when magnetic lines of force pass through the screw cylinder of a magnetically conductive metal material, numberless small vortexes are generated in the metal so that material in the screw cylinder reaches ideal heating effect. The screw cylinder device resulted from the invention makes use of electromagnetic induction principle to heat the screw cylinder and is provided with a heat preservation layer, a heat insulation layer and the like outside of the screw cylinder, thus solving the problem that heat is dispersed to air to maximize heat efficiency.

Owner:TONGXIANG ZHONGWEI CHEM FIBER

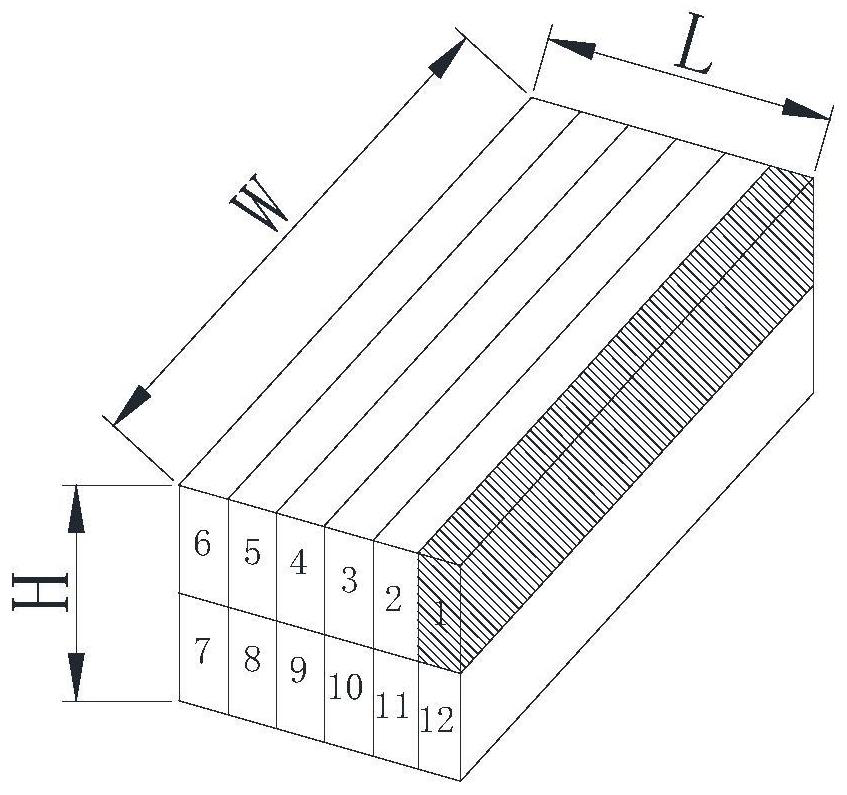

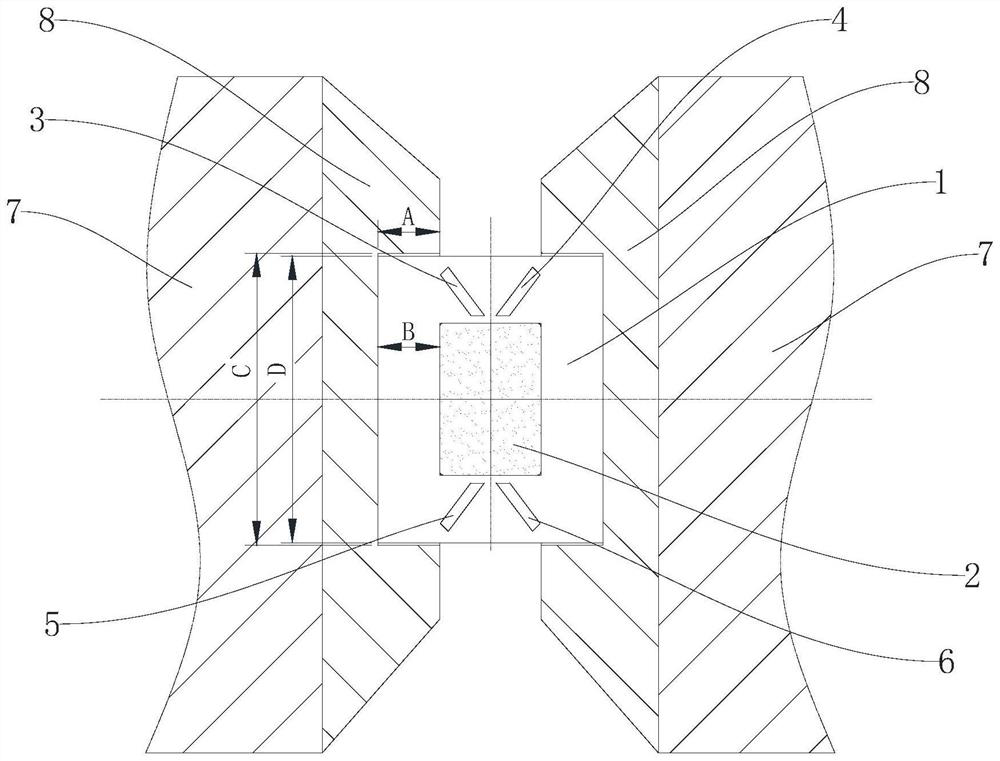

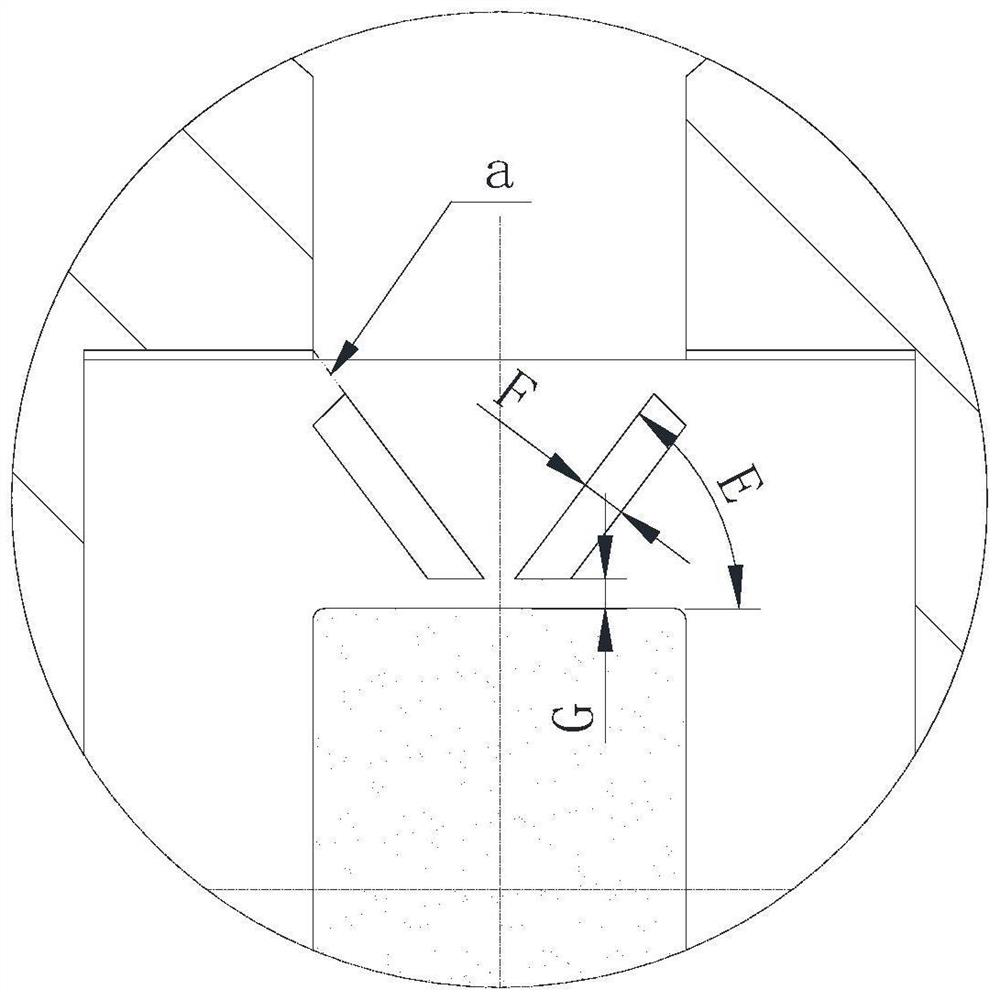

Method for reducing surface magnetic difference of two surfaces of sintered neodymium-iron-boron magnet

ActiveCN114373618AEliminate internal stressImprove liquidityInductances/transformers/magnets manufactureMagnetic materialsMagnetic polesInternal stress

The invention discloses a method for reducing double-sided surface magnetic difference of a sintered neodymium-iron-boron magnet, which is characterized in that a powder preparation process is improved, so that a lubricant can uniformly wrap and infiltrate powder particles, the internal stress of fine powder is fully removed, the flowability is obviously improved, the subsequent feeding uniformity is fully guaranteed, and the quality of the sintered neodymium-iron-boron magnet is improved. Meanwhile, the structures of the forming die and the magnetizing pole heads of the pressing machine are improved, so that the female die is clamped in open grooves of the two magnetizing pole heads, and the forming die and the pressing machine are clamped and matched, so that magnetic lines in a die cavity of the female die are distributed in parallel during magnetizing orientation, and the specific size of the die cavity of the female die is set; the magnetic field uniformity of the cavity of the female die is improved, the friction force between the periphery of the green body and the side wall of the cavity of the female die during forming and demolding is reduced, fine powder of each particle of the obtained green body does not generate obvious displacement after magnetizing orientation and pressing, and the density of the green body is uniform; the method has the advantages that the product percent of pass and the production efficiency can be improved while the double-sided surface magnetic difference of the sintered neodymium-iron-boron magnet is remarkably reduced.

Owner:BAOTOU YUNSHENG STRONG MAGNETIC MATERIAL +2

A nano-cold cathode electron source with a coplanar double-gate focusing structure and its manufacturing method

ActiveCN111081505BHigh field emission currentImprove gate control characteristicsDischarge tube main electrodesCold cathode manufactureNanowireElectron source

Owner:SUN YAT SEN UNIV

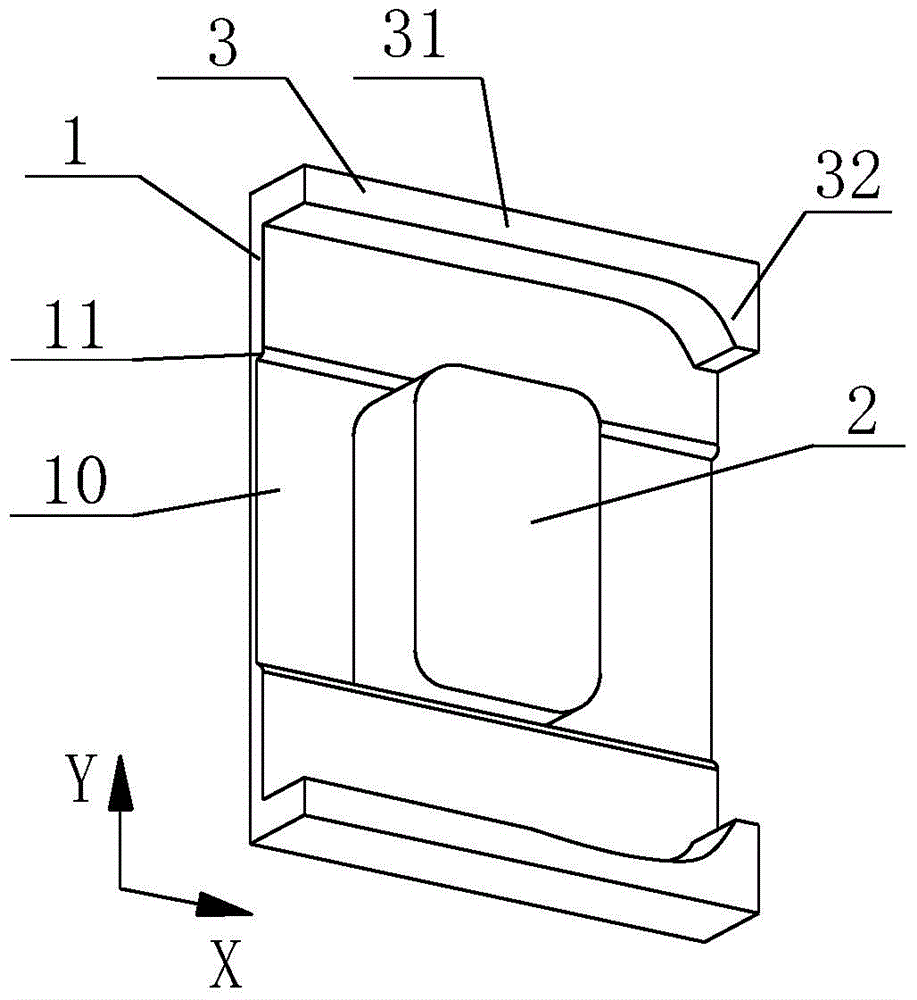

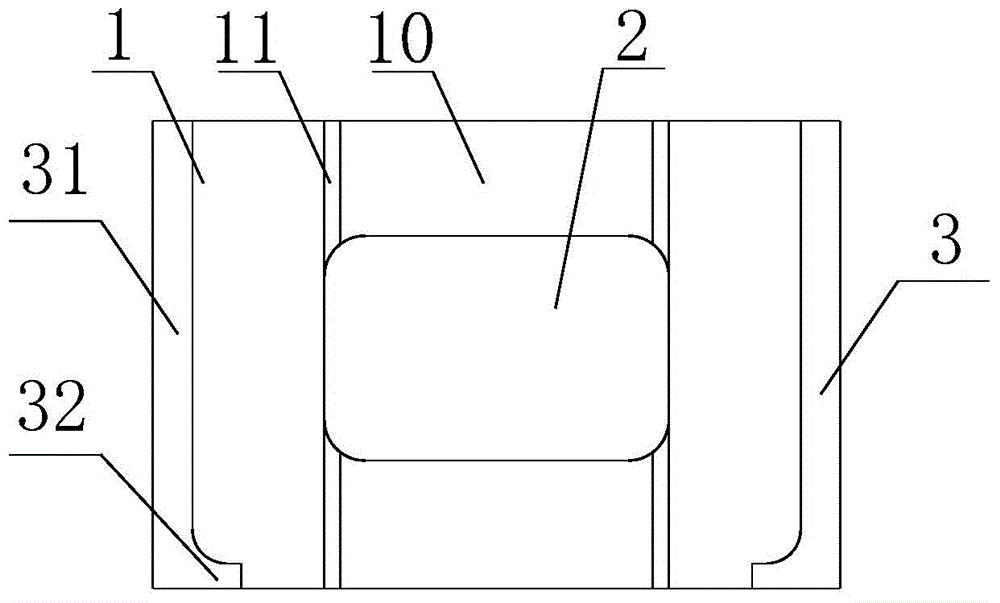

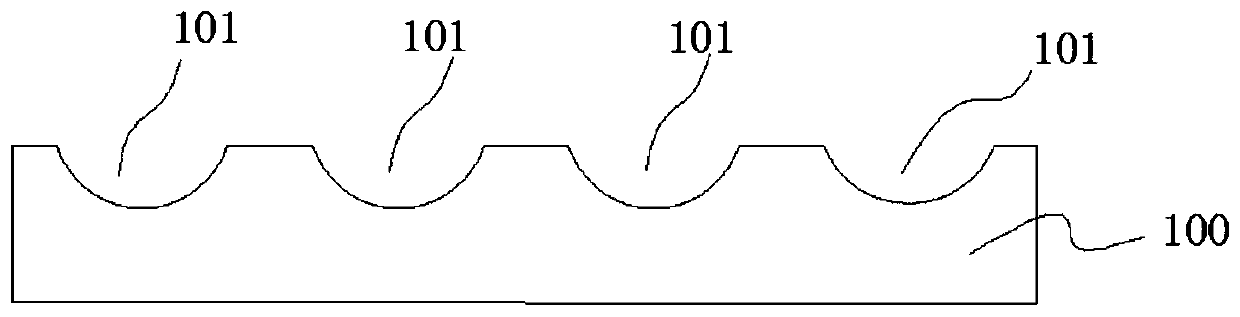

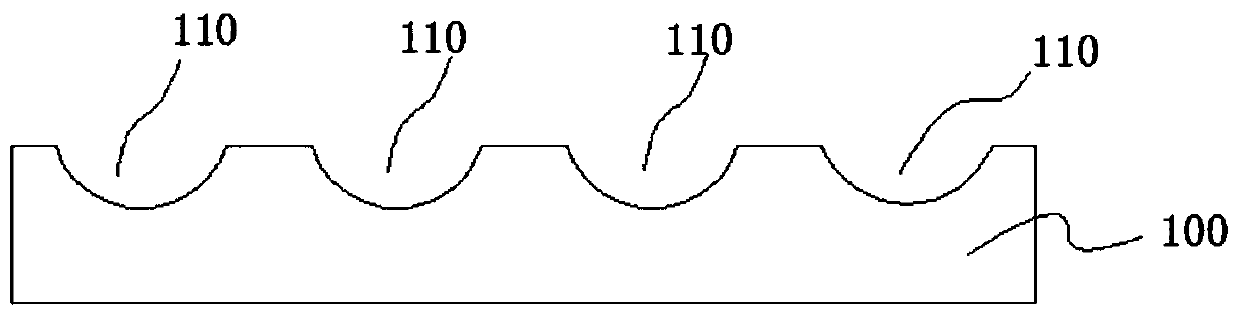

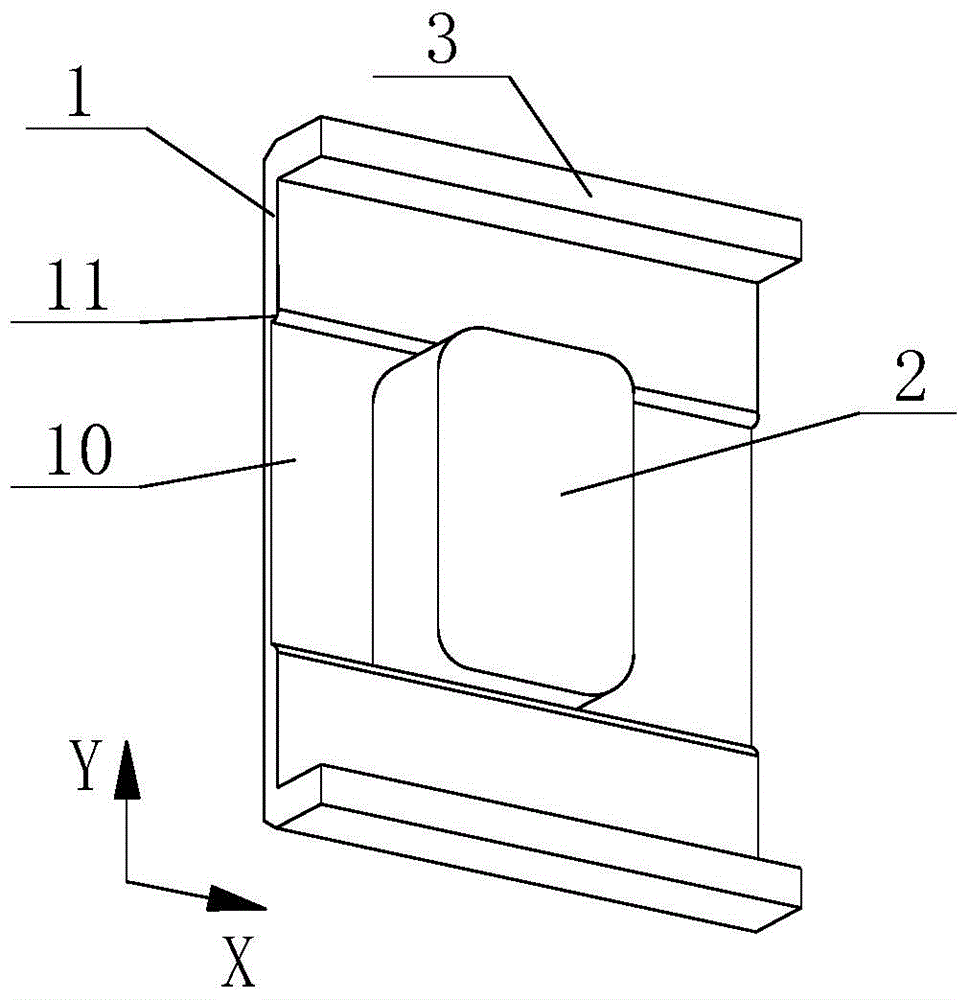

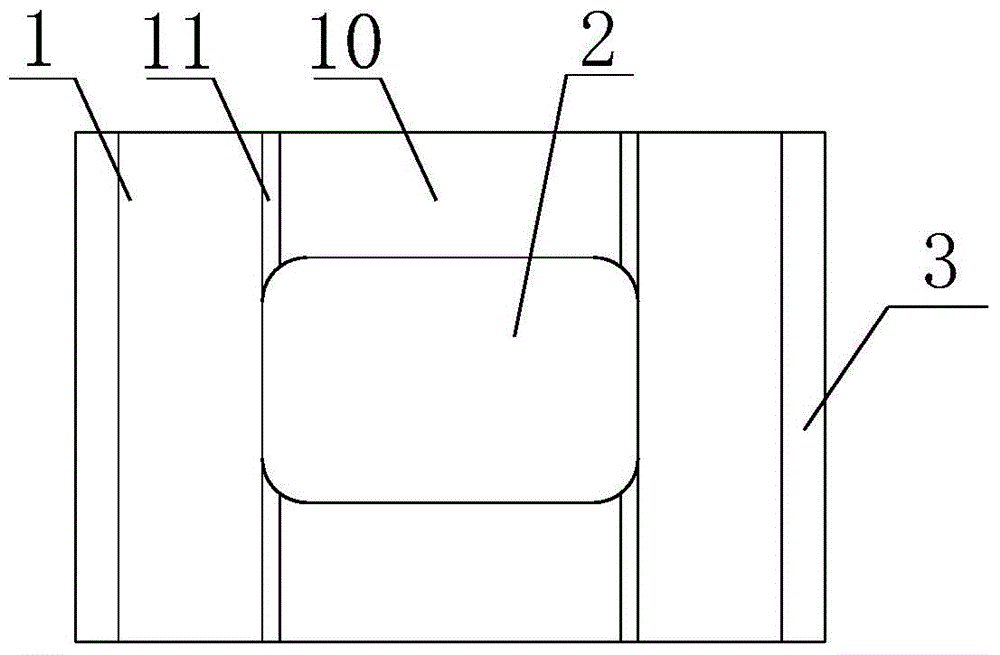

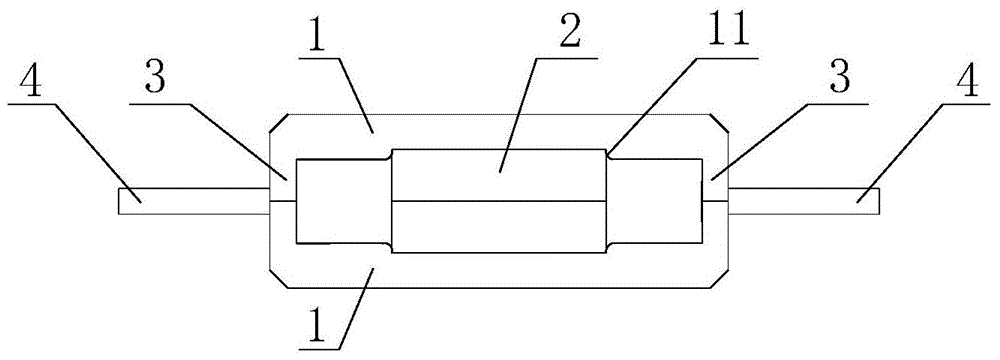

Planar magnetic core and circuit board applying magnetic core

InactiveCN103985516AReasonable structure layoutImprove stabilityTransformers/inductances magnetic coresPrinted circuit non-printed electric components associationConductor CoilElectrical and Electronics engineering

The invention discloses a planar magnetic core. Side plates have L-shaped structures consisting of long plates and short plates; the two side plates are positioned on both sides of a bottom plate in the length direction, and are vertical to the bottom plate; the long plate directions of the side plates are consistent with the width direction of the bottom plate, and the lengths of the long plates are equal to the width of the bottom plate; the short plates of the two side plates are positioned on the same side of the bottom plate; the length-width direction of a winding post is consistent with the length-width direction of the bottom plate; the distances D1 between the two ends of the winding post in the width direction and the two side plates D1 are smaller than the length R1 of the winding post; the distances D2 between both sides of the winding post in the length direction and both sides of the bottom plate in the length direction are smaller than the width R2 of the winding post; two grooves are formed in the bottom plate by extending from the two side faces of the winding post in the length direction to both sides of the bottom plate. According to the planar magnetic core disclosed by the invention, the magnetic core is reasonable in structural layout and large in the effective working area, so that the problem of divergence of coil magnetic induction lines on the root of the winding post is solved, and the stability and reliability of the electromagnetic property of the magnetic core are improved. The invention further provides a circuit board in which the planar magnetic core is applied.

Owner:ANHUI HUALIN MAGNETIC TECH

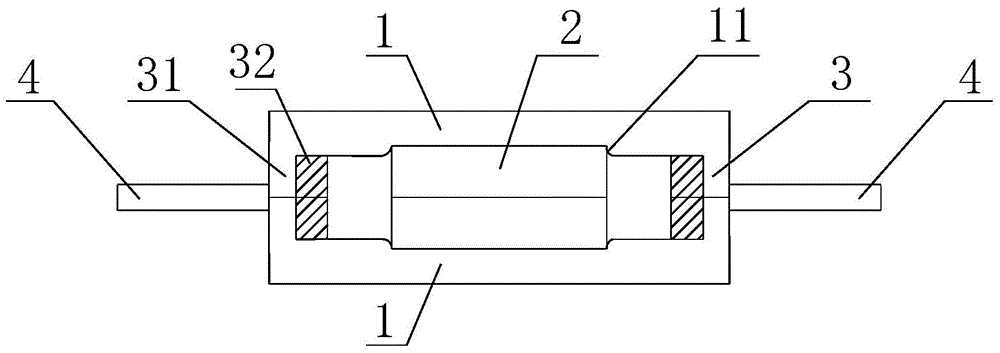

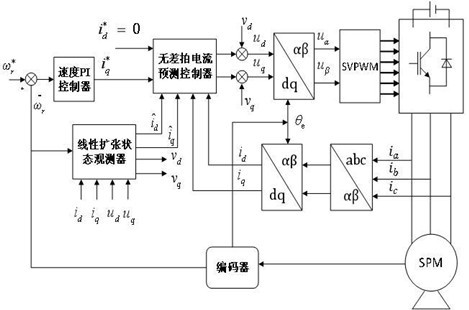

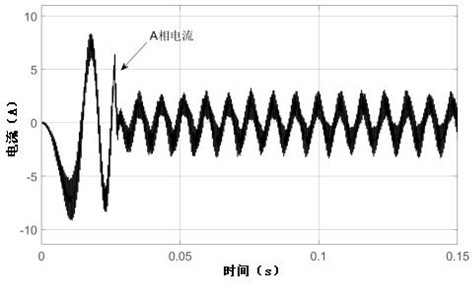

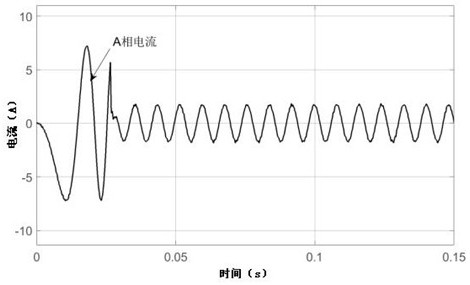

A high-reliability current predictive control method and system for a permanent magnet synchronous motor

ActiveCN109660170BImprove dynamic response performanceSolve the problem of low steady-state accuracyElectronic commutation motor controlAC motor controlElectric machineryMagnet

The patent of the present invention discloses a high-reliability current predictive control method and system for permanent magnet synchronous motors. Aiming at the above defects of deadbeat current predictive control, a linear expansion state observation is established according to the discrete mathematical model of permanent magnet synchronous motors. The controller is used to predict the current of the next cycle, and the voltage disturbance caused by parameter changes is observed, and the voltage disturbance is compensated to the deadbeat current predictive controller, which solves the problem of the permanent magnet synchronous motor using deadbeat current predictive control. Dependence, low robustness, low steady-state precision, and poor operational reliability, the method of the invention has fast dynamic response of the motor, high steady-state control precision, high robustness, and reliable operation.

Owner:SOUTHEAST UNIV

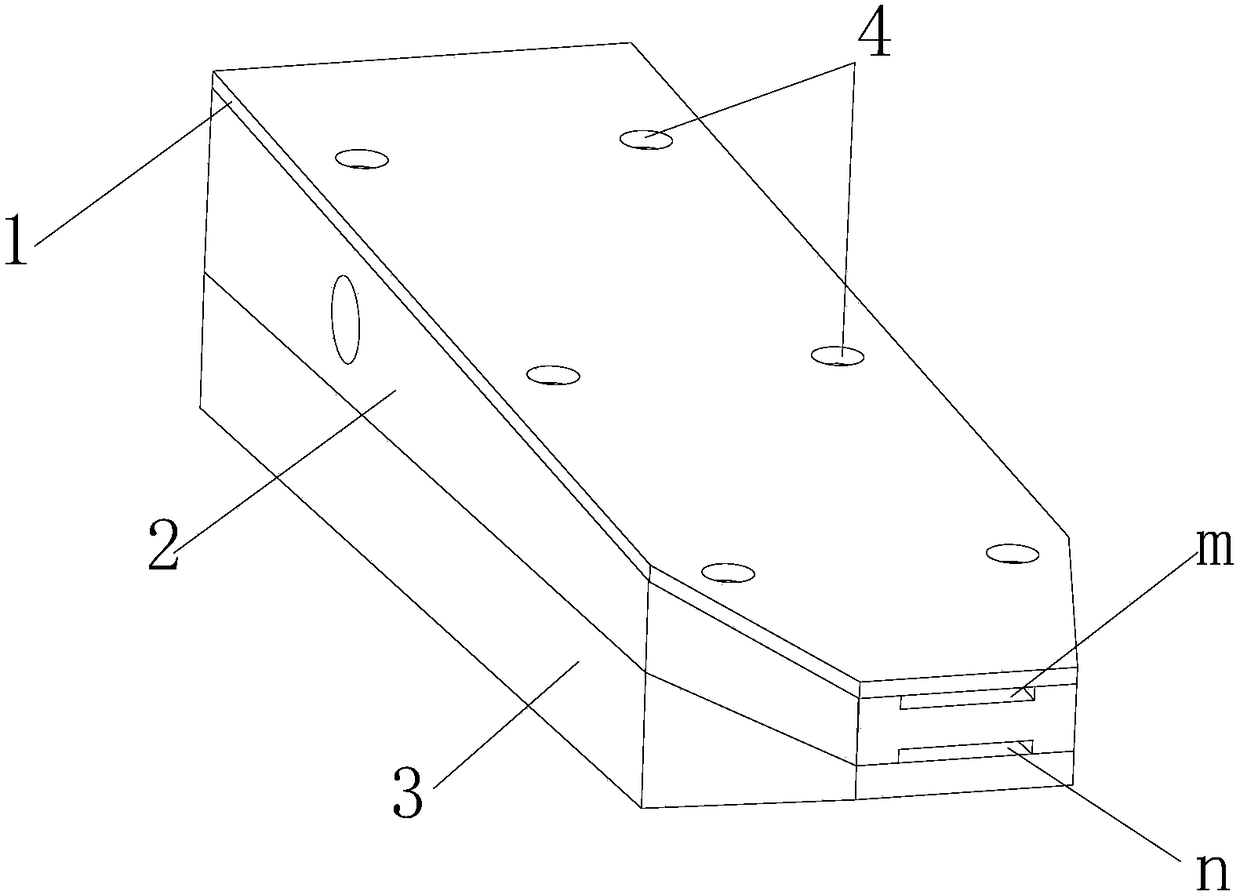

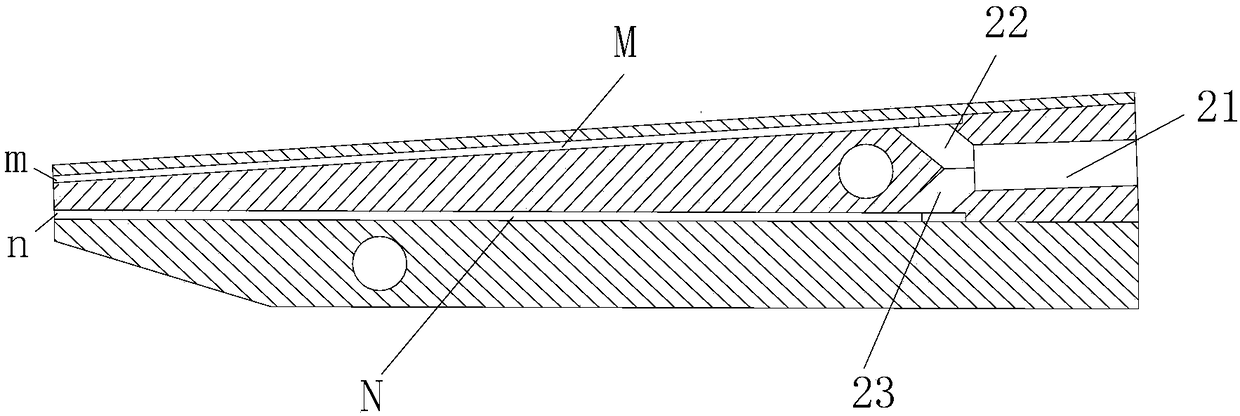

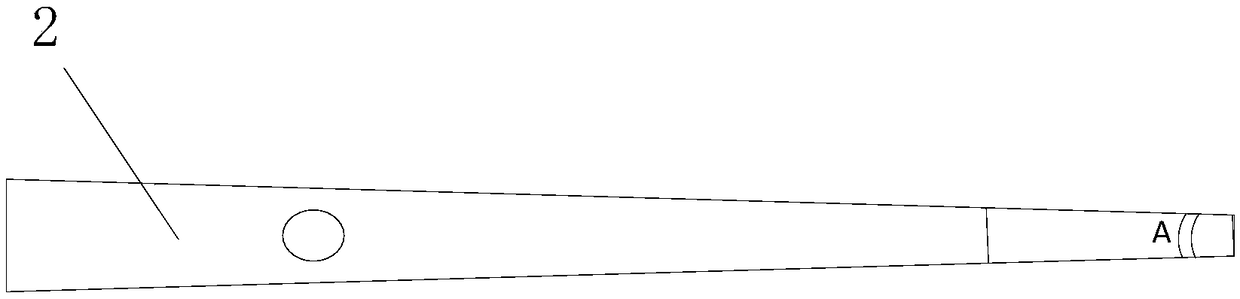

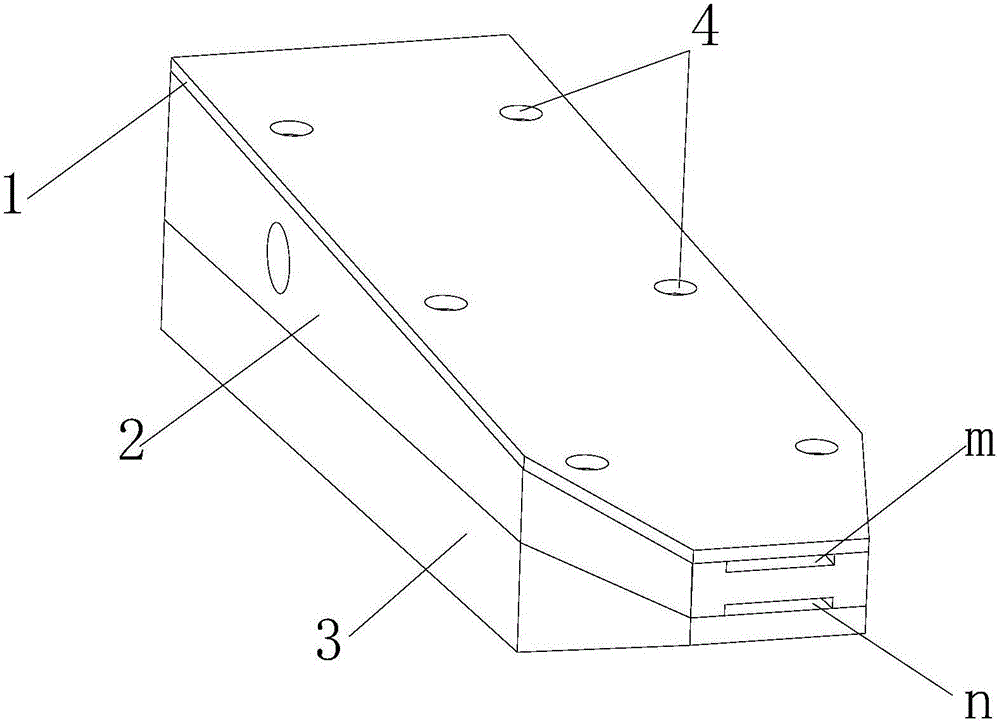

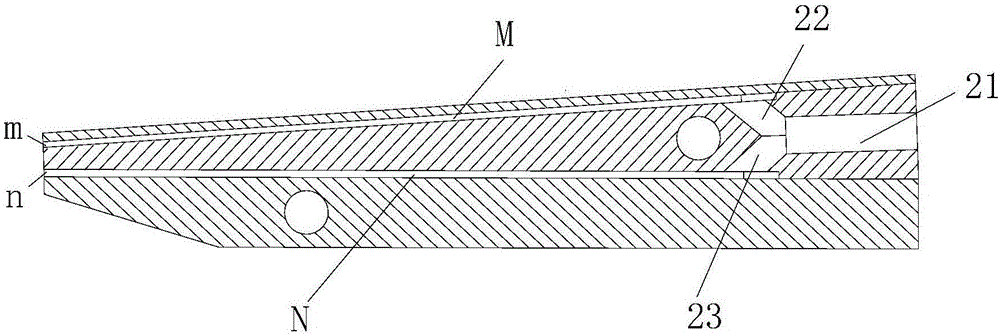

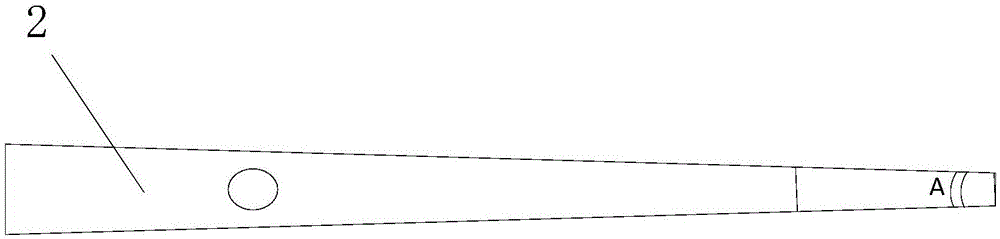

A double-channel converging side-axis powder feeding nozzle

ActiveCN106119837BSolve the problem of divergenceIncrease profitMetallic material coating processesEngineeringLarge head

A dual flow channel gathering type paraxial powder conveying feeding nozzle comprises a top plate, a wedge-shaped plate and a bottom plate which are sequentially horizontally overlapped from top to bottom and are mutually fixed, wherein a main flow channel is arranged at large head end of the wedge-shaped plate, and an inlet end of the main flow channel exposes from the side surface of the wedge-shaped plate to form a main inlet; an upper flow channel which extends along the top surface of the wedge-shaped plate is arranged between the top plate and the wedge-shaped plate; a lower flow channel which extends along the bottom surface of the wedge-shaped plate is arranged between the bottom plate and the wedge-shaped plate; the near end of the upper flow channel communicates with an outlet end of the main flow channel through a first flow distributing channel; the near end of the lower flow channel communicates with the outlet end of the main flow channel through a second flow distributing channel; a far end of the upper flow channel extends to the surface of a small head end of the wedge-shaped plate to form an upper flow channel outlet; the far end of the lower flow channel extends to the surface of the small head end of the wedge-shaped plate to form a lower flow channel outlet.

Owner:ZHEJIANG UNIV OF TECH

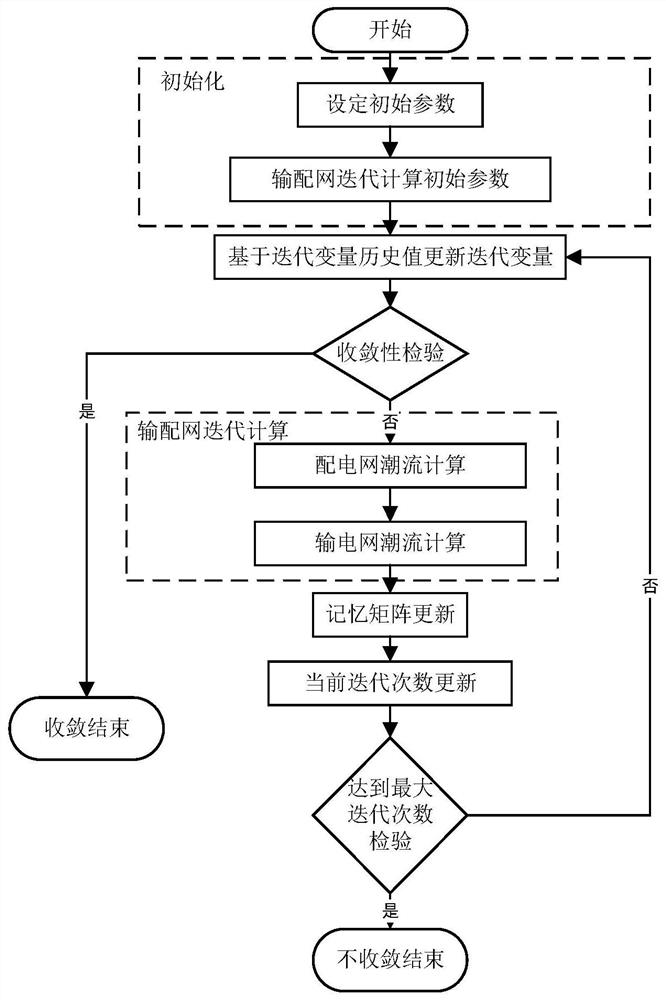

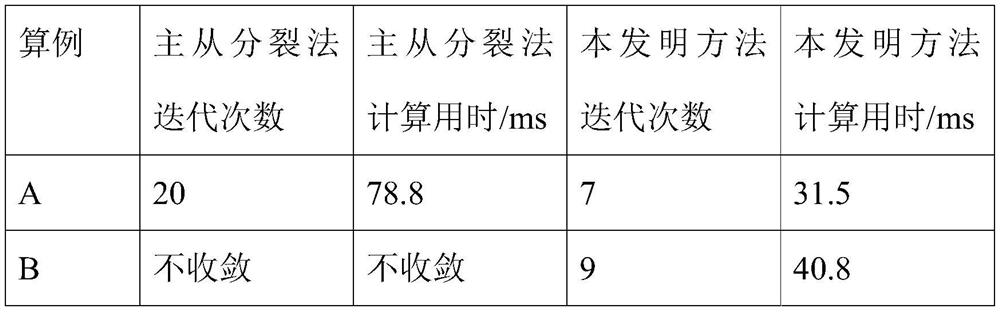

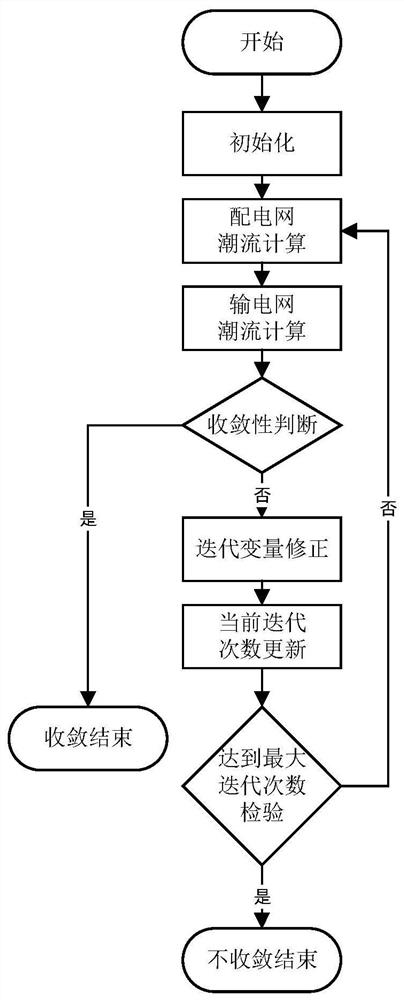

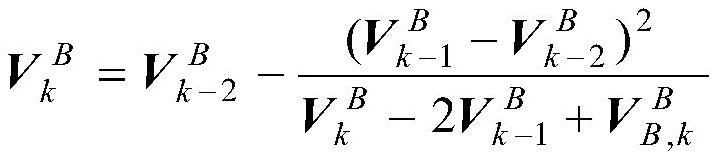

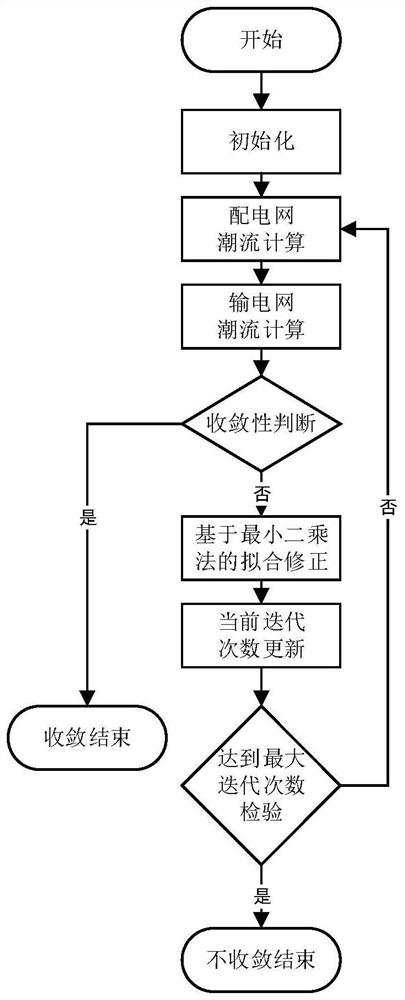

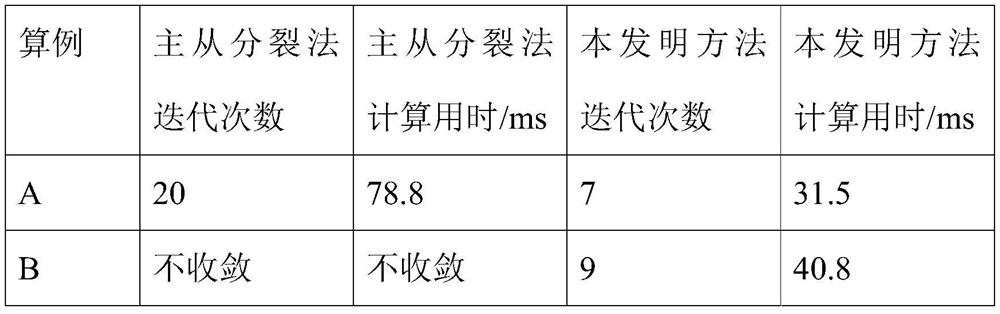

A Coordinated Power Flow Calculation Method for Transmission and Distribution Based on Iterative Variable Historical Value Update

ActiveCN112383064BImprove efficiencyImprove robustnessAc networks with different sources same frequencyVoltage amplitudeConvergence tests

The invention discloses a transmission and distribution collaborative power flow calculation method based on the update of the historical value of the iterative variable. The method includes seven main steps: initialization, updating the iterative variable based on the historical value of the iterative variable, convergence inspection, iterative calculation of the transmission and distribution network, and memory Matrix update, current iteration number update, maximum iteration number check. Compared with the traditional master-slave split method, the method of the present invention introduces a memory matrix, and updates the iterative variable based on the historical value of the iterative variable, which can significantly improve the efficiency and robustness of the overall algorithm for transmission and distribution coordinated power flow calculation, especially in the distribution network. When the disturbance of the transmission network is large, that is, when the sensitivity of the boundary node injection power to the boundary node voltage amplitude is high, it can solve the divergence problem of the traditional master-slave split method. At the same time, the method has strong operability and is easy to implement.

Owner:ZHEJIANG UNIV

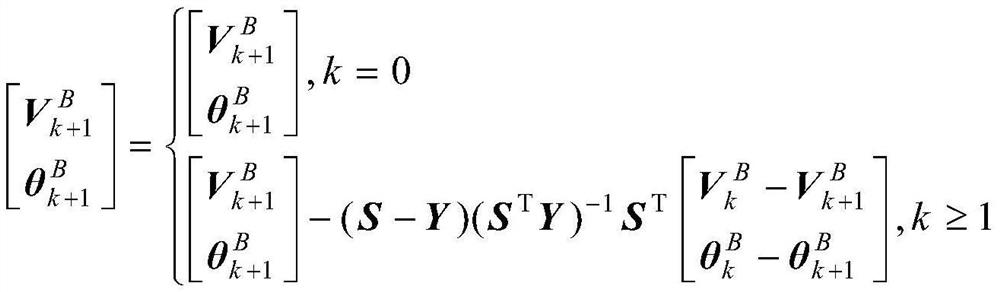

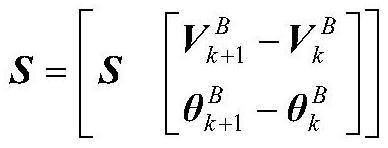

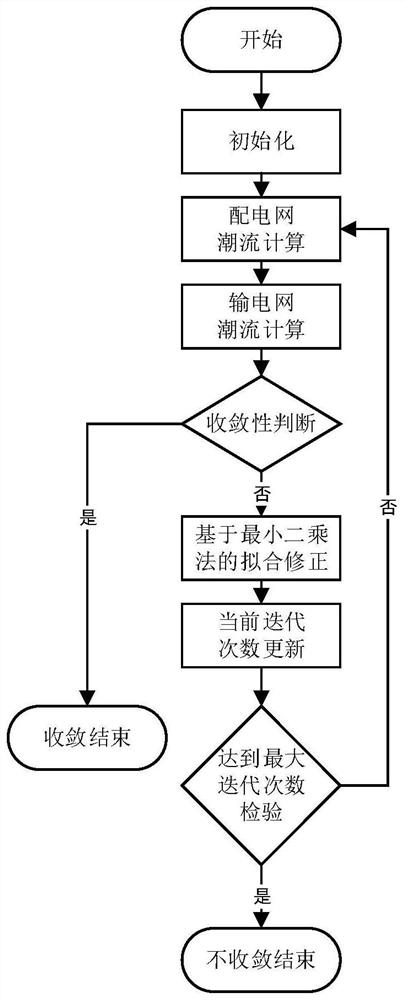

A Coordinated Power Flow Calculation Method for Transmission and Distribution Based on Least Squares Fitting and Correction

ActiveCN112383063BImprove efficiencyImprove robustnessAc networks with different sources same frequencyVoltage amplitudeConvergence tests

The invention discloses a transmission and distribution coordinated power flow calculation method based on least squares method fitting correction. The method includes the following seven main steps: initialization, distribution network power flow calculation, transmission network power flow calculation, convergence test, Fit correction for multiplication, update of the current iteration number, and verification of reaching the maximum number of iterations. In the method of the present invention, the iterative variable is fitted and corrected by using the least square method, which can significantly improve the efficiency and robustness of the overall algorithm for the transmission and distribution coordinated power flow calculation, especially when the distribution network has a large disturbance to the transmission network, that is, the boundary When the node injection power is highly sensitive to the voltage amplitude of the boundary nodes, it can solve the divergence problem of the traditional master-slave split method.

Owner:ZHEJIANG UNIV

Vehicle Cooperative Navigation Method Based on Relative Motion Model Constraints

ActiveCN110285804BSolve the problem of divergenceAchieve estimatesNavigation by speed/acceleration measurementsComplex mathematical operationsIn vehicleSimulation

The invention discloses a vehicle cooperative navigation method based on relative motion model constraints, and belongs to the technical field of vehicle cooperative navigation. In this method, the state equation of the cooperative navigation system is constructed on the basis of the error equation of the inertial navigation system; then the Doppler frequency shift effect is used to calculate the frequency offset of the vehicle-mounted wireless broadcasting due to the relative motion of the vehicle, and then the relative meeting time is judged; Establish the relative motion model of the vehicle and the measurement equation based on the relative motion model during the meeting; finally, the state equation and the measurement equation are discretized, and the measurement is updated during the meeting, and the system state quantity is fed back and corrected. Realize the effective modification of the cooperative navigation system. The invention can effectively utilize the relative motion constraint information of the vehicle in tunnels and other satellite navigation failure environments, realize effective integration with inertial navigation, improve the accuracy and reliability of the vehicle navigation system, and is suitable for engineering applications.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A Position Estimation Method Based on Multi-sensor Integrated Navigation

ActiveCN105021198BHigh positioning accuracyCost-effectiveNavigational calculation instrumentsEquation of stateVelocity measurement

The invention discloses a position estimation method based on integrated navigation of multiple sensors. The method comprises the following steps: 1, parameters output by a DR, a GPS, a DME, a VOR and an ADC are acquired; 2, a state equation is established; 3, a position and velocity measurement equation of the GPS, a slope distance measurement equation of the DME and an azimuth measurement equation of the VOR are calculated; 4, a comprehensive measurement equation is established according to each measurement equation; 5, by combining the state equation and the comprehensive measurement equation, position error amount and velocity error amount are estimated; and 6, according to the estimated position error amount and velocity error amount, output correction is carried out on the DR system, and position estimation is finished. According to the invention, there is no need to use an inertial navigation system. The method provided by the invention has high positioning accuracy, high reliability and good real-time performance, is economic, effective and easy for engineering realization, and can meet high-precision and high-reliability positioning requirements of civil aircrafts.

Owner:上海航空电子有限责任公司

Dual flow channel gathering type paraxial powder conveying feeding nozzle

ActiveCN106119837ASolve the problem of divergenceIncrease profitMetallic material coating processesEngineeringLarge head

A dual flow channel gathering type paraxial powder conveying feeding nozzle comprises a top plate, a wedge-shaped plate and a bottom plate which are sequentially horizontally overlapped from top to bottom and are mutually fixed, wherein a main flow channel is arranged at large head end of the wedge-shaped plate, and an inlet end of the main flow channel exposes from the side surface of the wedge-shaped plate to form a main inlet; an upper flow channel which extends along the top surface of the wedge-shaped plate is arranged between the top plate and the wedge-shaped plate; a lower flow channel which extends along the bottom surface of the wedge-shaped plate is arranged between the bottom plate and the wedge-shaped plate; the near end of the upper flow channel communicates with an outlet end of the main flow channel through a first flow distributing channel; the near end of the lower flow channel communicates with the outlet end of the main flow channel through a second flow distributing channel; a far end of the upper flow channel extends to the surface of a small head end of the wedge-shaped plate to form an upper flow channel outlet; the far end of the lower flow channel extends to the surface of the small head end of the wedge-shaped plate to form a lower flow channel outlet.

Owner:ZHEJIANG UNIV OF TECH

A system architecture construction method

ActiveCN105512403BHigh demand coverageReduce dependenceConstraint-based CADSpecial data processing applicationsComputer architectureData stream

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

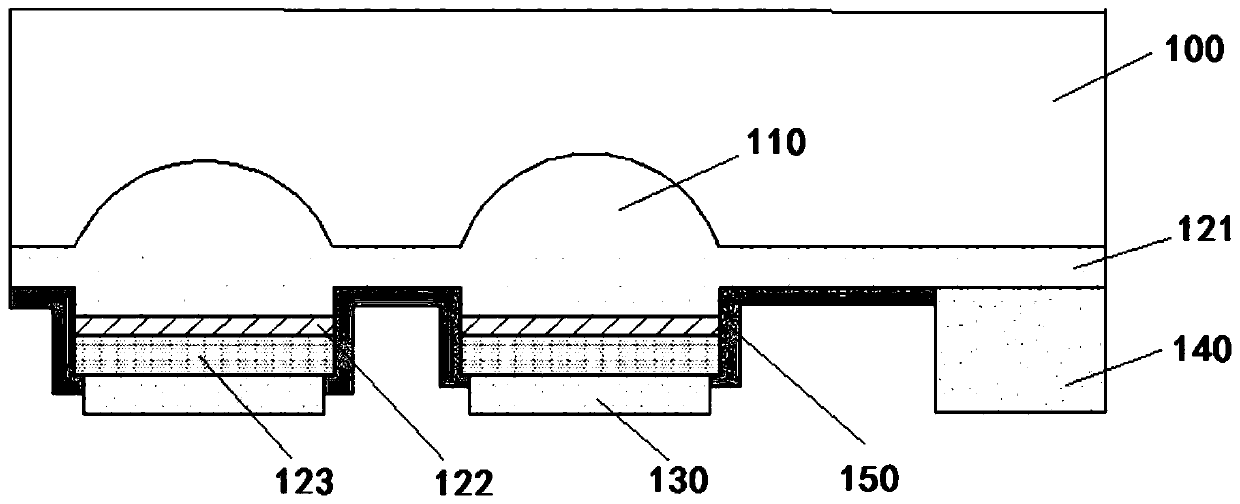

A flip-chip led microdisplay array and manufacturing method thereof

ActiveCN106206605BHigh-resolutionEasy to gatherSolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexContact layer

The invention discloses an LED micro display array flip chip and a manufacturing method. The flip chip comprises a substrate, a plurality of grooves, a transparent thin film layer and an LED micro pixel array arranged on the substrate, wherein the plurality of grooves are etched in the substrate in an array; the grooves are filled with the transparent thin film layer; various LED micro pixels correspond to the grooves one by one; a refractive index of the transparent thin film layer is greater than 2.3; the transmittance on blue light or green light is greater than 97%; each LED micro pixel comprises an N-type GaN layer, a multi-quantum well layer and a P-type GaN layer which are sequentially deposited on the substrate; the N-type GaN layers of the LED micro pixel array are connected into a whole to form a common cathode, and an N electrode metal contact layer is deposited on the common cathode; and a P electrode metal contact layer is deposited on the P-type GaN layers in an LED micro pixel region. According to the LED micro display array flip chip, a transparent thin film layer material with a high refractive index is deposited on the substrate, so that better convergence of light-emitting layer light sources is achieved; the problem that light is diffused after entering a sapphire substrate with a low refractive index is solved; interference of outlet light between pixel units is reduced; and the resolution of the LED micro display array is improved.

Owner:上海君万微电子科技有限公司

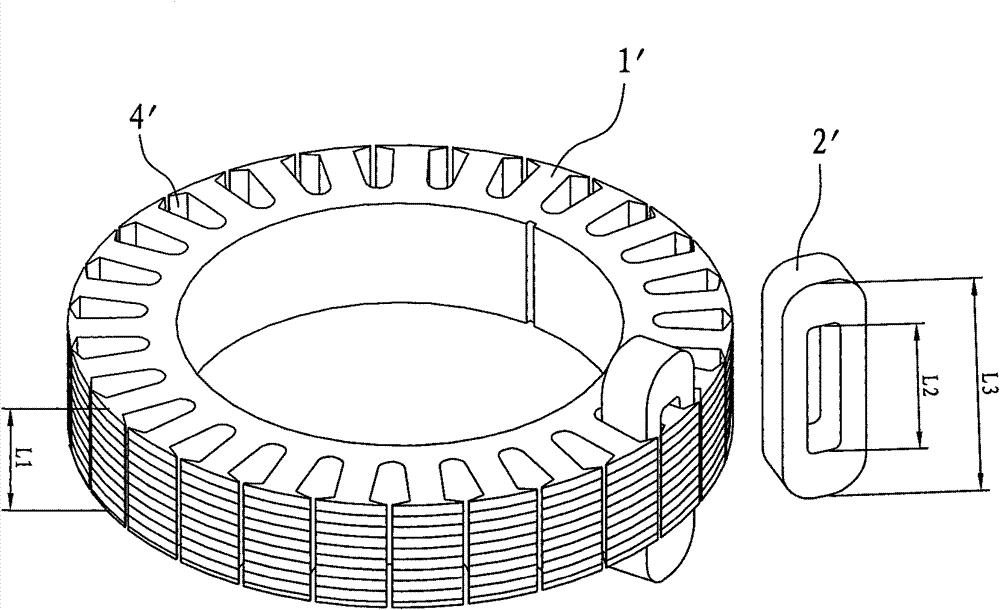

Magnetic core and circuit board using magnetic core

InactiveCN103985517AOptimized designIncrease the effective working areaTransformers/inductances magnetic coresPrinted circuit non-printed electric components associationMagnetic coreRidge

The invention discloses a magnetic core. The magnetic core consists of a bottom plate, two side plates and a winding post, wherein the two side plates are arranged on the two sides in the length direction of the bottom plate and are vertical to the bottom plate; the width of the bottom plate is equal to the length of the two side plates; the winding post is arranged on the middle part of the bottom plate; the length direction of the winding post is consistent to that of the bottom plate; the distance L1 from the two sides of the width direction of the winding post to the two side plates is greater than the distance L2 from the two sides of the length direction of the winding post to the two side plates; the length R1 of the winding post is greater than L1; the width R2 of the winding post is greater than L2; two grooves are formed in the bottom plate from the two sides of the length direction of the winding post to the two sides of the bottom plate in an extending way; the side ridges of the winding post are in smooth transition; the height of the two side plates is equal to that of the winding post. The magnetic core provided by the invention is reasonable in structural layout, the problem that coil magnetic induction wires at the root of the winding post scatter is solved, and meanwhile, the stability and the reliability of electromagnetic characteristics of the magnetic core are improved. The invention also provides a circuit board using the magnetic core.

Owner:ANHUI HUALIN MAGNETIC TECH

Transmission and distribution cooperative rapid robust load flow calculation method

InactiveCN112398134AImprove efficiency and robustnessStrong maneuverabilityAc networks with different sources same frequencyVoltage amplitudeEngineering

The invention discloses a transmission and distribution cooperative rapid robust load flow calculation method. The method mainly comprises seven sub-steps of initialization, power distribution networkload flow calculation, power transmission network load flow calculation, convergence check, iteration variable correction, current iteration frequency updating and maximum iteration frequency check.According to the method, the iteration variable values of two adjacent iteration steps are used for correcting the iteration variable, the efficiency and robustness of the whole transmission and distribution collaborative load flow calculation algorithm can be remarkably improved, and especially when the disturbance of the power distribution network to the power transmission network is large, which means that the sensitivity of boundary node injection power relative to a boundary node voltage amplitude is high, a problem of divergence of a traditional master-slave splitting method can be solved. Meanwhile, the method is high in operability and easy to implement.

Owner:ZHEJIANG UNIV

A multifunctional vehicle police light

ActiveCN104566114BIncrease success rateEasy to usePlanar light sourcesLighting support devicesLight beamEngineering

The invention discloses a multi-function vehicle police lamp. The multi-function vehicle police lamp comprises a base, a support, a lamp body, a driving mechanism and a control circuit. The multi-function vehicle police lamp is characterized in that a power output end of the driving mechanism is connected with the support and a power input end of the lamp body to drive the support to rotate and drive the lamp body to swing; LED (Light Emitting Diode) lamp beads and a camera are arranged inside the lamp body; a control output end of the control circuit is connected with the LED lamp beads and an input end of the camera; the LED lamp beads are controlled to emit the light which is irradiated on a target and the camera is controlled by the control circuit through the reflection of the target to perform photographing or video shooting on the target; a single light-emitting color can be adopted by all of the LED lamp beads to form a single-color continuous or flashing light-emitting structure or multiple different light-emitting colors are adopted by the LED lamp beads to form a multi-color continuous or flashing light-emitting structure through arrangement and combination. According to the multi-function vehicle police lamp, light beams can be adjusted, the irradiation range is wide, and the rapid shooting can be achieved.

Owner:广州市德晟光电科技股份有限公司

Transmission and distribution cooperative power flow calculation method based on least square method fitting correction

ActiveCN112383063AImprove efficiency and robustnessStrong maneuverabilityAc networks with different sources same frequencyVoltage amplitudeLeast squares

The invention discloses a transmission and distribution cooperative power flow calculation method based on least square method fitting correction. The method comprises the following seven main steps of initialization, power distribution network power flow calculation, power transmission network power flow calculation, convergence inspection, fitting correction based on a least square method, current iteration frequency updating and maximum iteration frequency inspection. According to the method, the least square method is used for carrying out fitting correction on the iteration variables, theefficiency and robustness of the whole transmission and distribution cooperative load flow calculation algorithm can be remarkably improved, and especially when the disturbance of a power distribution network to a power transmission network is larger, namely the sensitivity of boundary node injection power relative to the boundary node voltage amplitude is higher, the problem of divergence of a traditional master-slave splitting method can be solved.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com