Method for heating screw cylinder of spinning machine and device thereof

A heating method and spinning machine technology, applied in induction heating devices, coil devices, induction heating and other directions, can solve the problems of power loss and waste, short service life, rising ambient temperature, etc., to increase the service life, improve the working environment, The effect of reducing the ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

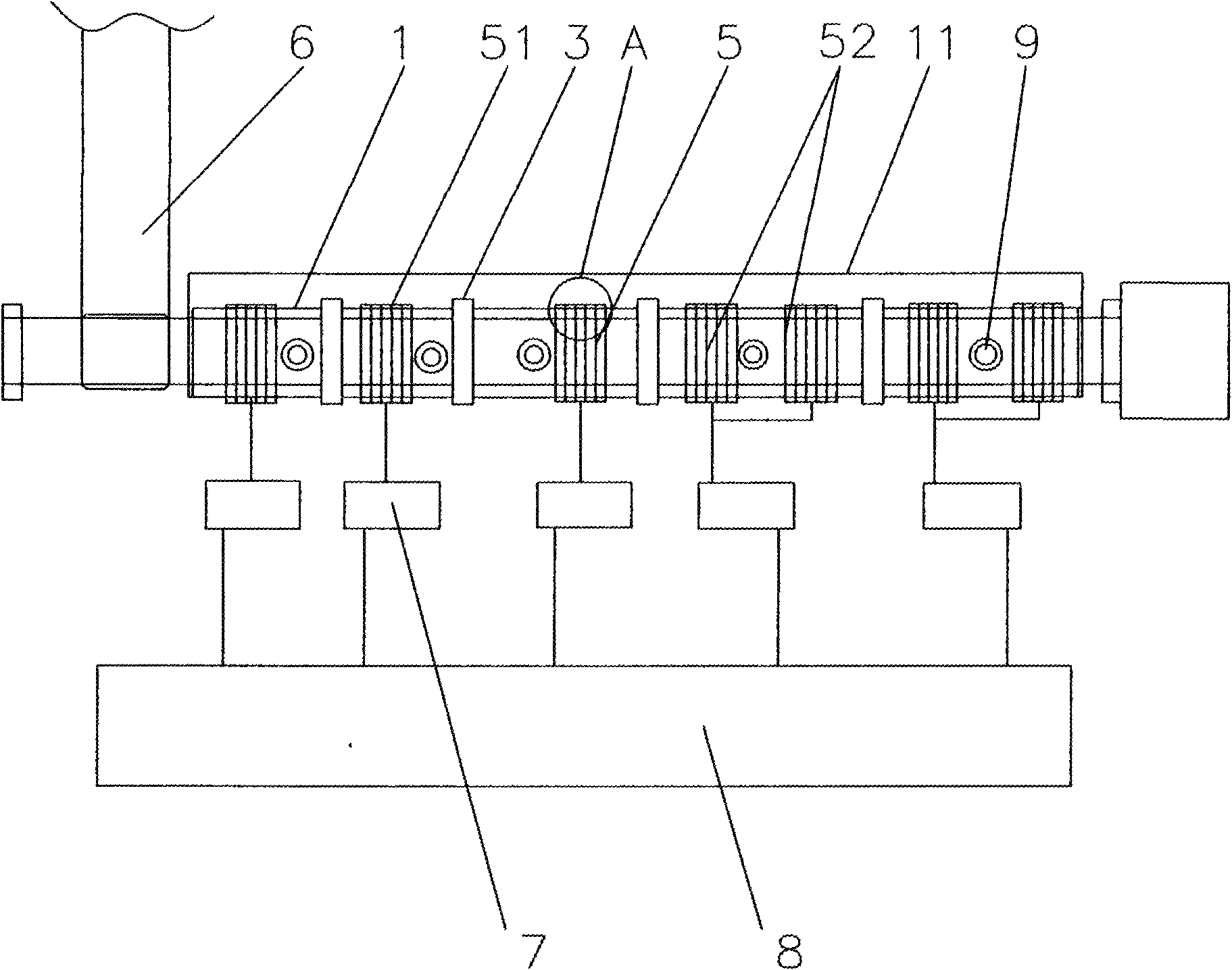

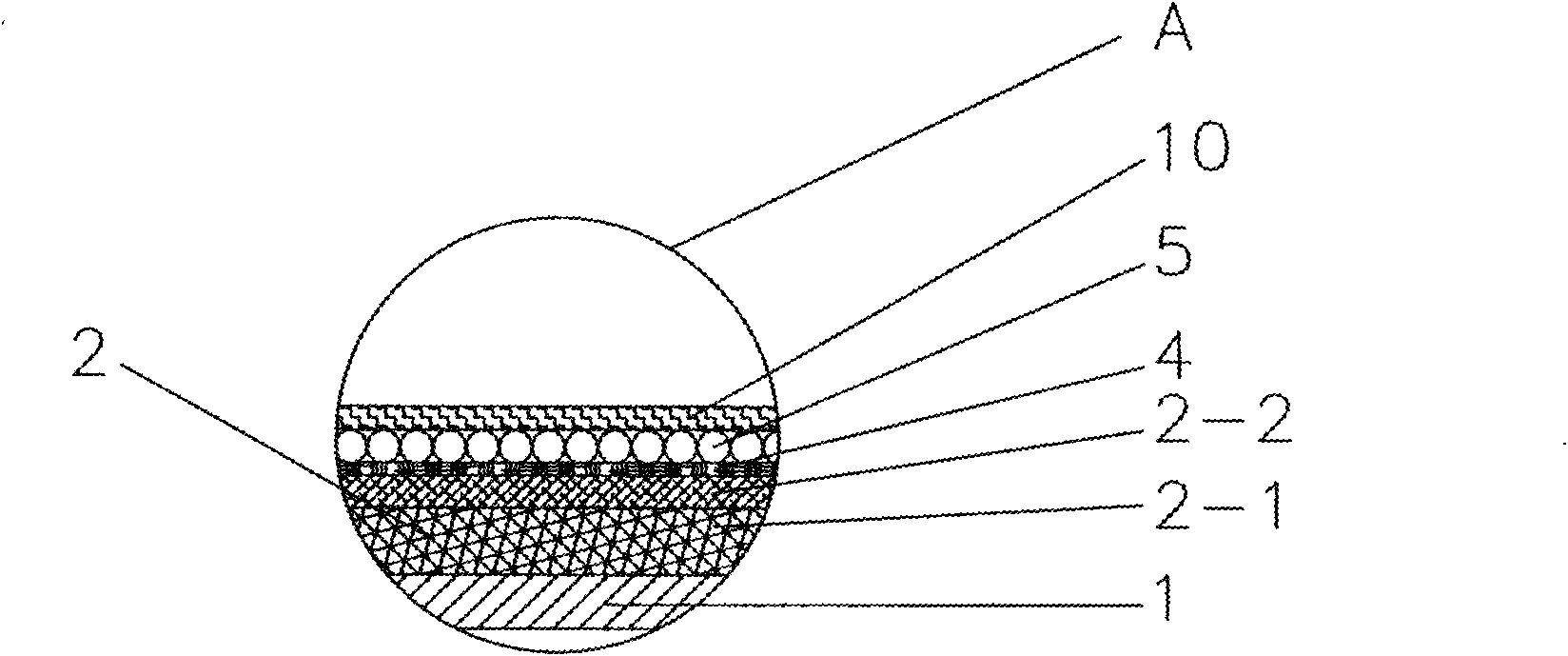

[0014] Such as figure 1 , figure 2 As shown, the screw barrel device described in this embodiment mainly includes a screw barrel 1, and a heat preservation material composed of aluminum silicate insulation cotton 2-1 with a thickness of 15 mm and a high temperature resistant cloth 2-2 is laid outside the screw barrel 1. Layer 2, high temperature resistant cloth 2-2 is evenly wound on the aluminum silicate thermal insulation cotton 2-1 layer by layer, and then an insulating board with a thickness of 1 mm is set on the thermal insulation layer 2 as an insulating device 4 through rivets, and is wound layer by layer on the insulating board The induction coil 5 is generally composed of a high temperature resistant wire with a high temperature resistance of 500°C. A heat-shrinkable sleeve 10 is sheathed outside the induction coil 5 , both ends of the induction coil 5 are connected to ceramic joints, and the induction coil 5 is electrically connected to the electromagnetic controll...

Embodiment 2

[0018] Such as figure 1 As shown, the method for heating the screw barrel of the spinning machine described in this embodiment is suitable for the screw of Ф105 mm and below Ф105 mm, and the 220V, 50 / 60Hz alternating current is connected to the electrical control cabinet 8, and the electrical control cabinet 8 controls The electromagnetic controller 7 converts the alternating current into a direct current, and then converts the direct current into a high-frequency current with a frequency of 20-40KHz. The high-speed changing high-frequency current will generate a high-speed changing alternating magnetic field through the induction coil. When the magnetic field When the magnetic lines of force pass through the screw barrel 1 of magnetically conductive metal material, countless small eddy currents will be generated in the metal, which will make the screw barrel 1 itself heat up rapidly and reach a heating temperature of 280 ° C ~ 310 ° C ± 1 ° C, so that the inside of the screw b...

Embodiment 3

[0021] In the screw barrel device described in this embodiment, the insulating device 4 to which it belongs is to pass the wire of the induction coil 5 in the insulating bead, and then set it on the heat insulating layer 2 .

[0022] And the screw barrel heating method of the spinning machine using this screw barrel device, the screw diameter is above Ф105 mm, the used three-phase four-wire 380V power supply is used, and three electromagnetic heating coils are used for heating in each heating zone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com