A flip-chip led microdisplay array and manufacturing method thereof

A flip-chip, micro-display technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of inter-pixel light interference, spot enlargement, etc., to achieve the effect of improving resolution and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments.

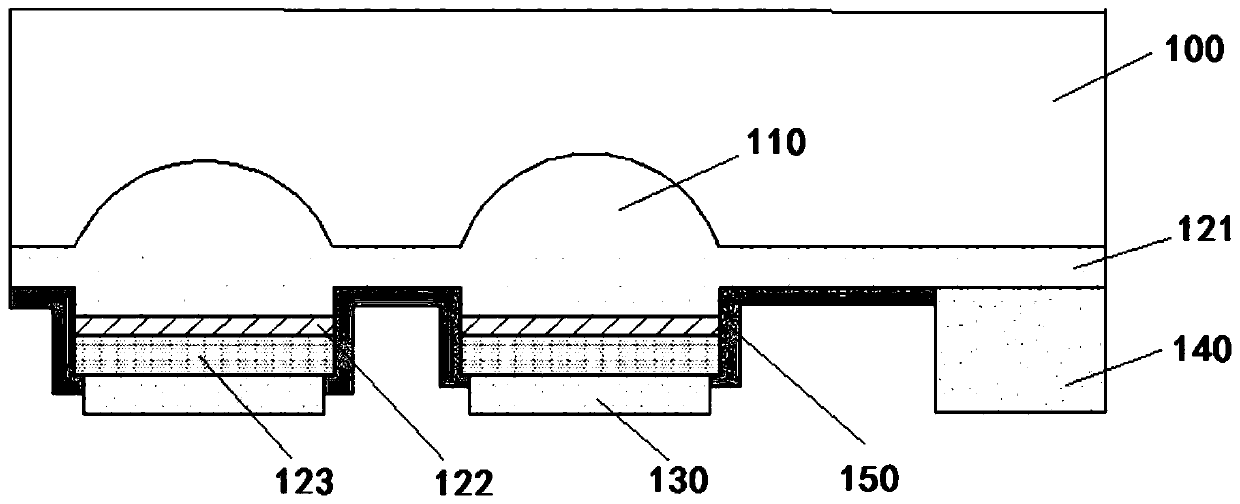

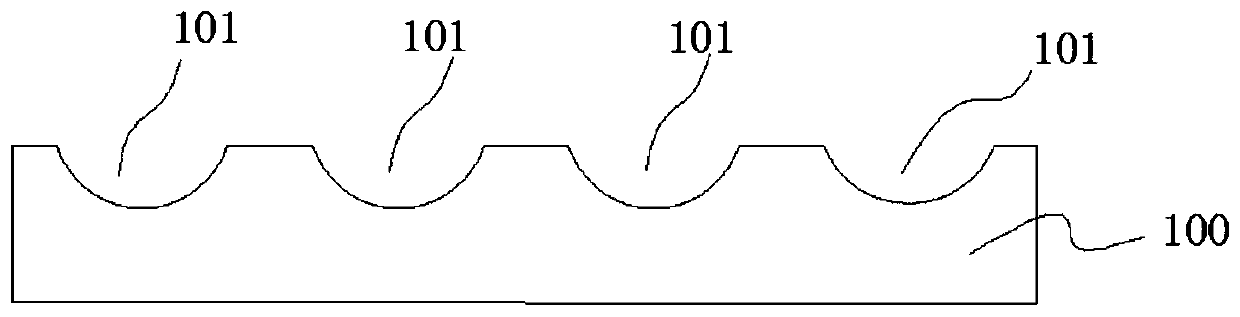

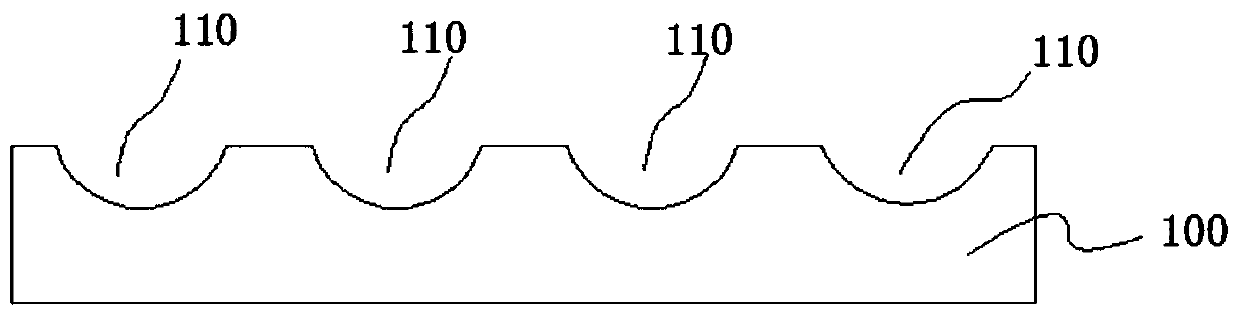

[0033] Such as figure 1 A LED micro-display array flip-chip shown includes a sapphire substrate 100, a plurality of grooves 101 etched in an array on the sapphire substrate 100, a transparent film layer 110 filled in the grooves 101 and deposited on the sapphire substrate. LED micro-pixel array on the bottom 100.

[0034] Such as figure 2 As shown, the grooves 101 are hemispherical grooves with a diameter of 5-25 μm, and the arrays are distributed on the substrate 100 at equal intervals. The transparent thin film layer 110 is filled in the groove 101, the transparent thin film layer 110 has a refractive index>2.3, and a transmittance of blue light or green light>97%.

[0035] Such as figure 1 with 5 As shown, each LED micro-pixel corresponds to the groove 101 one by one, and a SiOx or SiNx insulating layer 150 is provided between them. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com