Magnetic core and circuit board using magnetic core

A circuit board and magnetic core technology, which is applied in the direction of printed circuits connected with non-printed electrical components, transformer/inductor magnetic cores, etc. Large effective working area, reasonable structure layout and design, solving the effect of coil magnetic field line divergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

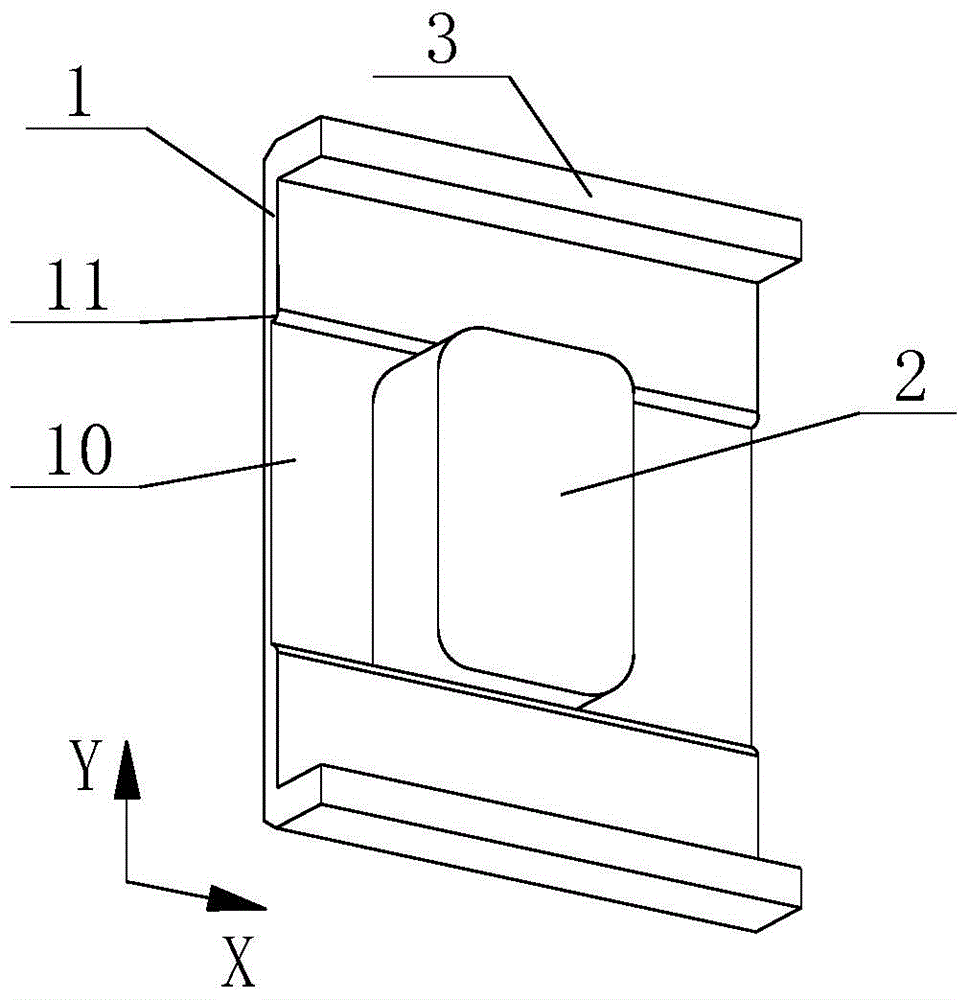

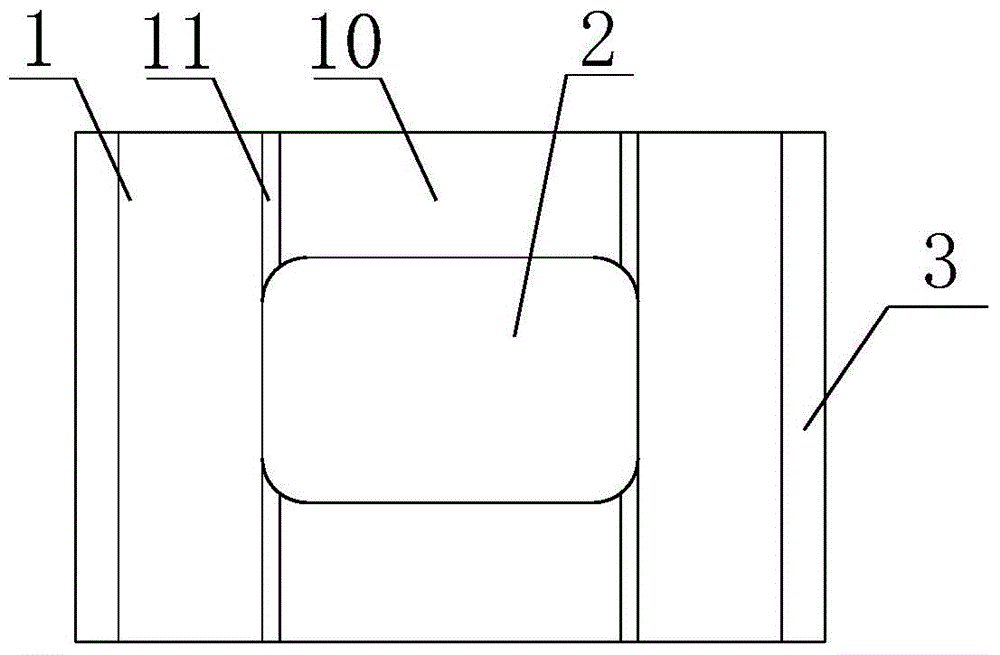

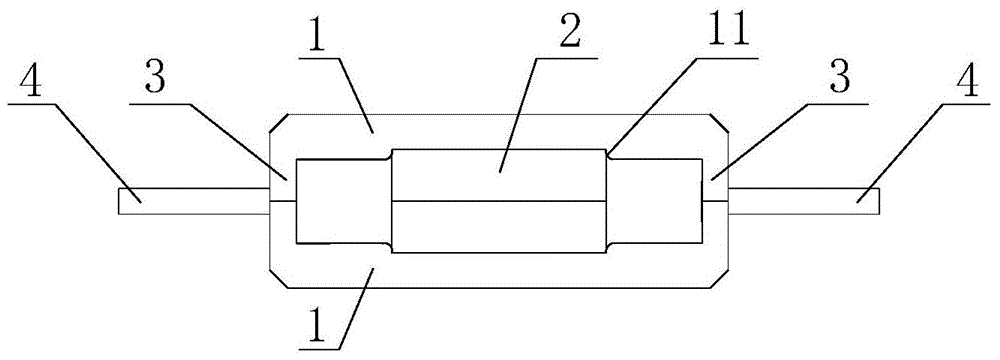

[0018] Such as Figures 1 to 3 as shown, figure 1 It is a structural schematic diagram of a magnetic core proposed by the present invention, figure 2 for figure 1 Front view of the proposed magnetic core, image 3 for figure 1 A side view of the proposed core mounted to a circuit board.

[0019] refer to figure 1 and 2 , a magnetic core proposed by the present invention is composed of a bottom plate 1, two side plates 2 and a winding post 3;

[0020] The shape of the bottom plate 1 and the side plate 2 is rectangular, and the winding post 3 is a cuboid. The two side plates 2 are arranged on both sides of the length direction of the bottom plate 1 and are perpendicular to the bottom plate 1. The width D2 of the bottom plate 1 is the same as the length C1 of the two side plates 2. Equal, the winding post 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com