Method for reducing surface magnetic difference of two surfaces of sintered neodymium-iron-boron magnet

A neodymium iron boron and magnet technology, which is used in the manufacture of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of low molding production efficiency, inability to directly improve the magnetic difference between the two surfaces, and long production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

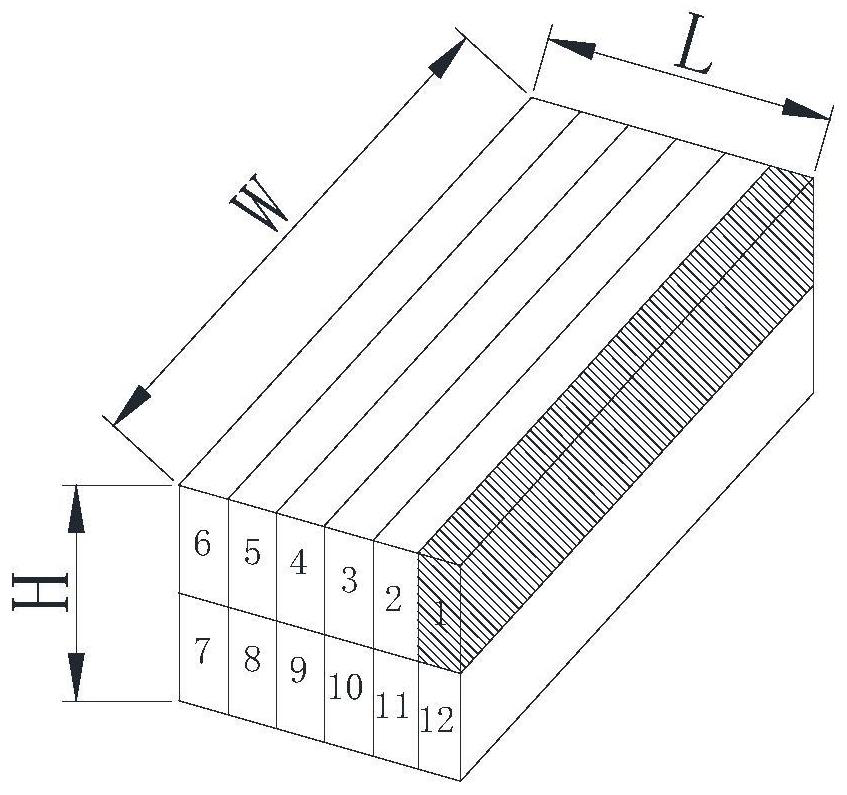

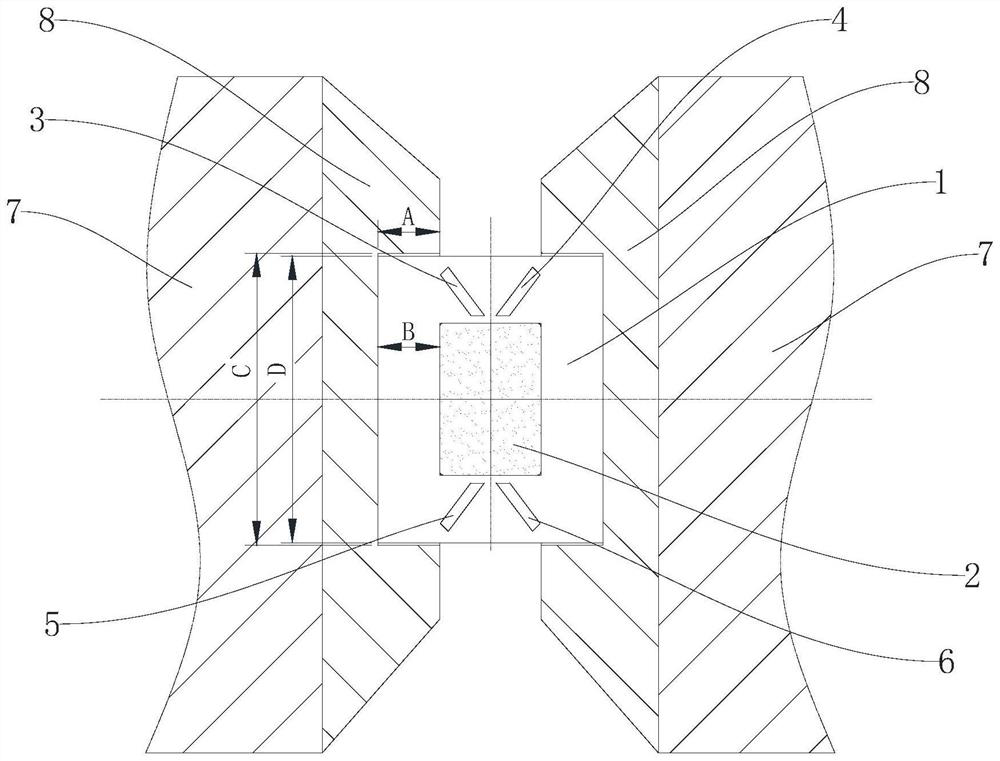

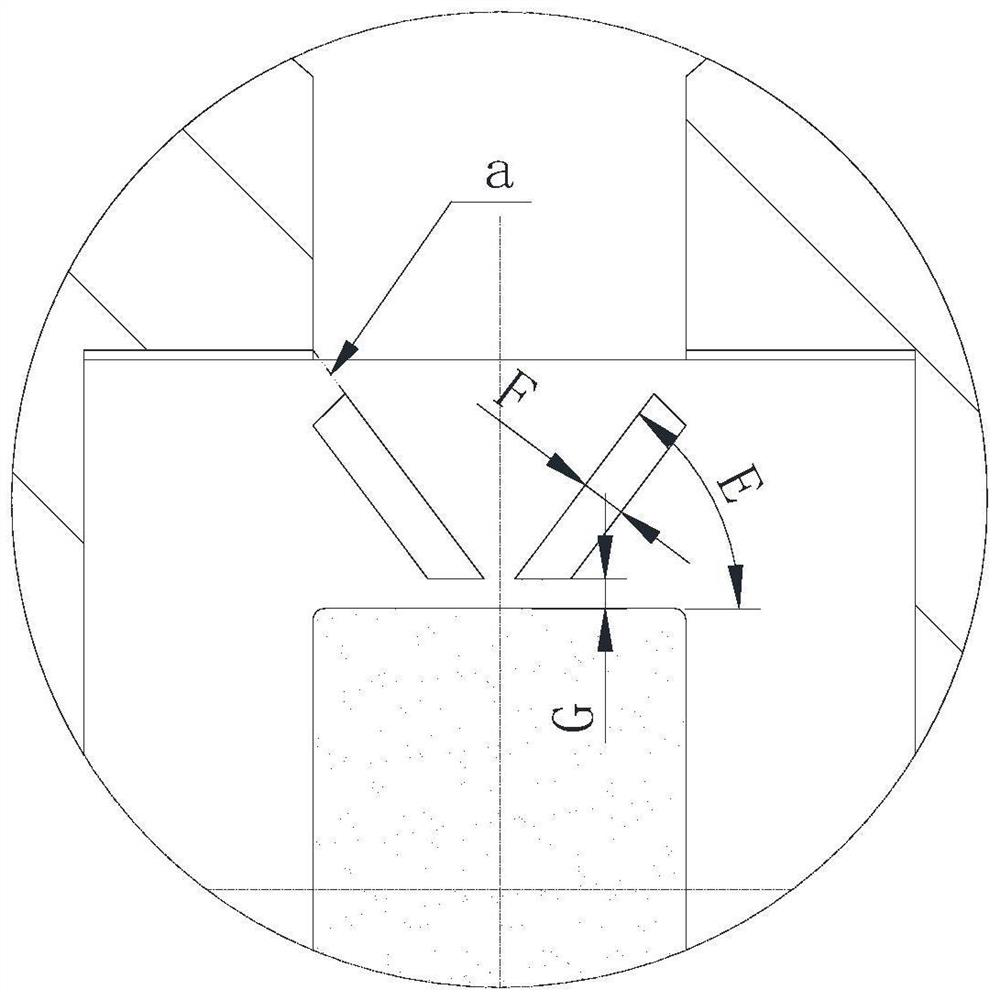

[0020] Example: such as Figure 1 ~ Figure 3 As shown, a method for reducing the difference in surface magnetism on both sides of a sintered NdFeB magnet comprises the following steps:

[0021] (1) Complete the batching operation of sintered NdFeB magnets according to the formula, use a melting furnace to prepare cast pieces, crush and remove impurities and send the cast pieces to hydrogen crushing furnace for hydrogen crushing to obtain hydrogen crushed powder, and hydrogen crushed powder Sorting the materials, removing the undersize material with a particle size below 5 μm and the oversize material with a particle size above 100 μm to obtain hydrogen crushed powder with a particle size range of 5 μm to 100 μm. Add lubricant to the hydrogen crushed powder and mix it evenly before entering Jet milling equipment is used to grind powder to obtain a fine powder with a particle size of 4±0.1 μm. The mixing time of hydrogen crushed powder and lubricant is controlled to 90 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com