A high-reliability current predictive control method and system for a permanent magnet synchronous motor

A permanent magnet synchronous motor and current prediction technology, which is applied in the control system, motor control, vector control system, etc., can solve the problems of low steady-state accuracy, low robustness, poor operation reliability, etc., and achieve low steady-state accuracy , improve robustness and operational reliability, and enhance the effect of dynamic response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

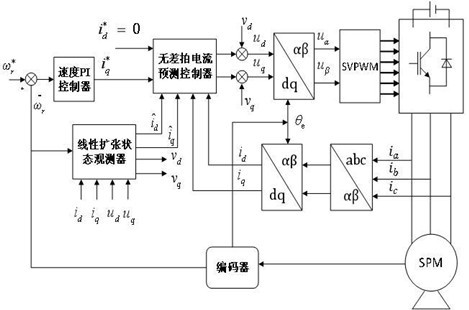

[0042] A high-reliability current prediction control system for permanent magnet synchronous motors, including an acquisition system, a coordinate transformation system, a deadbeat current prediction controller, a linear expansion state observer, and a PI speed controller. The encoder of the actual speed of the magnetic synchronous motor and the sensor used to collect the current of the permanent magnet synchronous motor; the deadbeat current prediction controller is used to output the dq axis voltage; the PI speed controller is used to calculate the given value of the dq axis current; The linear expansion state observer is used to obtain the dq axis current prediction value of the permanent magnet synchronous motor and the dq axis voltage interference caused by parameter changes;

[0043]The coordinate transformation system is respectively connected with the acquisition system and the modulation module, and predicts the current of the next cycle through the linear expansion st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com