Nanometer cold cathode electron source of coplanar double-gate focusing structure and manufacturing method of nanometer cold cathode electron source

A technology of focusing structure and cold cathode, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc. Spotting, solving divergence, improving the effect of gate control characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This example prepares ZnO nanometer cold cathode electron source

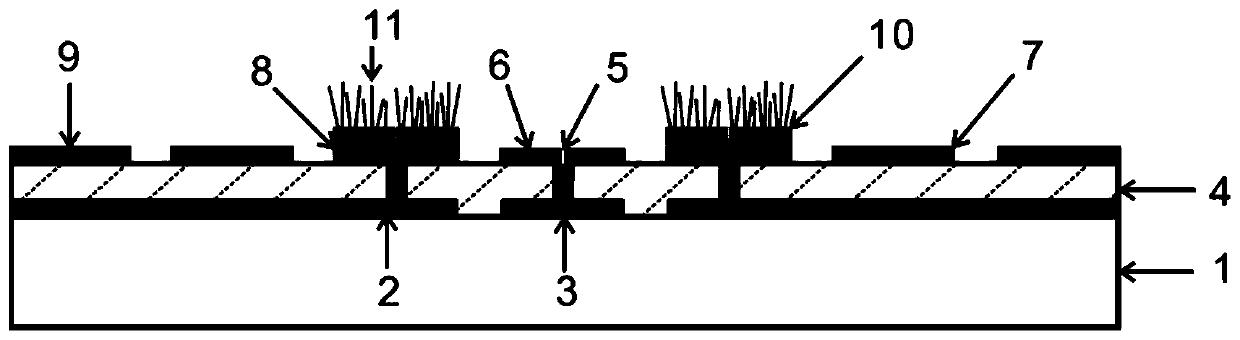

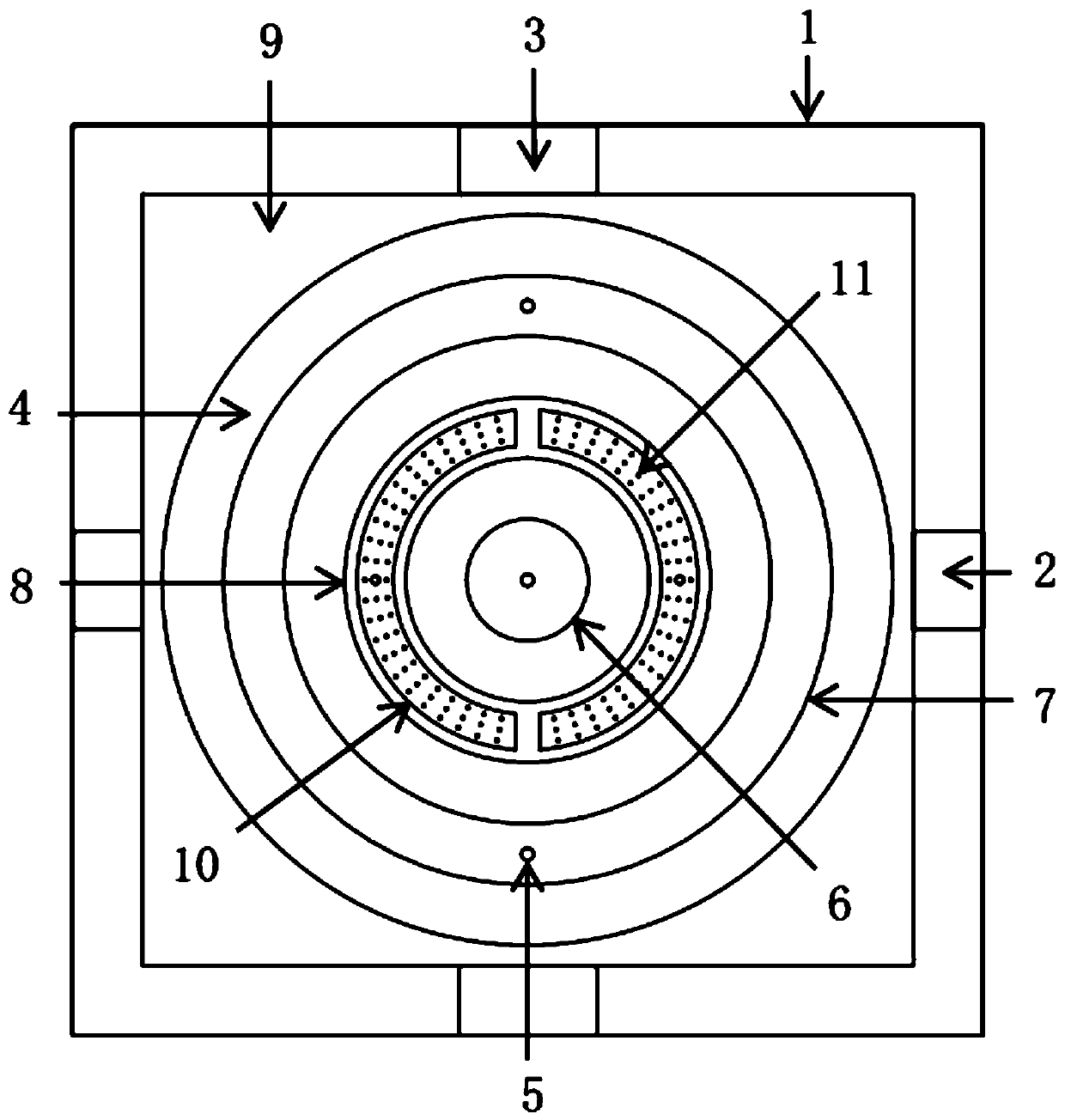

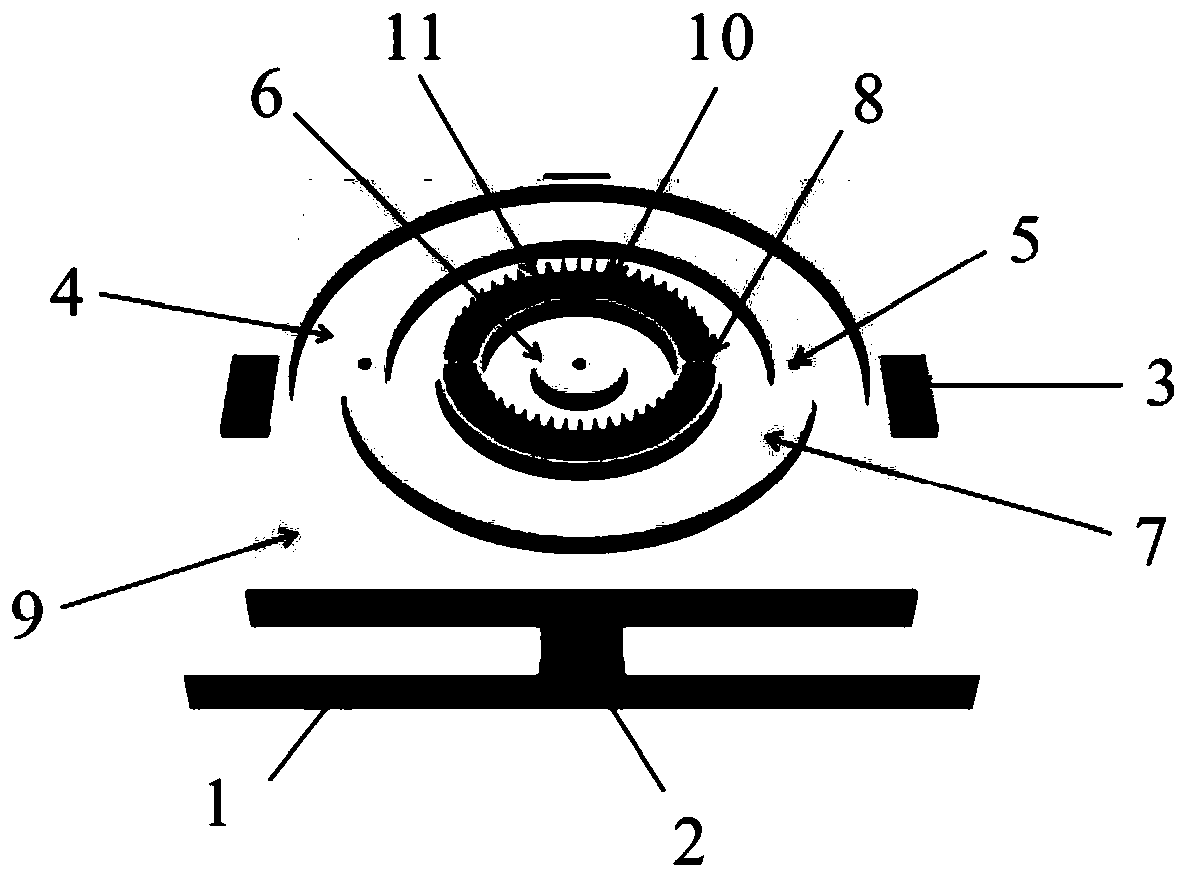

[0050] Such as Figure 1-Figure 3 As shown, the nano-cold cathode electron source of the coplanar double-gate focusing structure of the present invention includes a substrate 1, a bottom segmented cathode electrode 2, a bottom gate electrode 3, an insulating layer 4, an etched via hole 5, and a top layer internal gate Electrode 6, top-layer external ring-shaped gate electrode 7, top-layer ring-shaped cathode electrode 8, focusing electrode 9, growth source film 10, nanowire cold cathode 11.

[0051] There are two bottom segmented cathode electrodes 2 located on both sides of the bottom grid electrode 3 , and the outer leads of the bottom segment cathode electrodes 2 and the bottom grid electrode 3 are vertically arranged. The insulating layer 4 covers the bottom segmented cathode electrode 2 and the bottom grid electrode 3, and the insulating layer 4 is respectively etched with a number of etching throu...

Embodiment 2

[0061] The nano-cold cathode electron source array of the coplanar double-gate focusing structure in this embodiment is basically the same as that in Embodiment 1, as Figure 5 As shown, the difference is that the bottom grid electrodes form electrodes arranged in columns, and the segmented cathode electrodes on the bottom layer form electrodes arranged in rows under the connection of the ring-shaped cathode electrodes on the bottom layer. The design can make the bottom segmented cathode electrode and the bottom gate electrode perpendicular to each other on the same plane, so that the electron source array composed of the electron source has row and column addressing capability. The electron sources arranged in an array can repel the emitted electron beams by applying a negative voltage to the focusing electrode to produce a focusing effect, thereby realizing the micro-focus spot of the electron source.

Embodiment 3

[0063] The nano-cold cathode electron source of the coplanar double-gate focusing structure is basically the same as that of Embodiment 1, the difference is that

[0064] (1) The cathode substrate 11 is a large-area silicon wafer.

[0065] (2) The bottom segmented cathode electrode 2 and the bottom gate electrode 3 are made of Al, and the thickness range is 1 μm.

[0066] (3) The insulating film as the insulating layer 13 is composed of a silicon nitride insulating film; the thickness of the insulating layer is 1 μm;

[0067] (4) The top inner grid electrode 6, the top outer annular grid electrode 7, the top annular cathode electrode 8, and the focusing electrode 9 are made of AZO, and the thickness range is 2 μm;

[0068] (5) On the top ring-shaped cathode electrode 8, photolithographically locate the growth region of the nanowire cold cathode 11, and then deposit the growth source film 10; the growth source film 10 is molybdenum, and its thickness is 2.5 μm; the growth sour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com