Spliced stator iron core of tractor

A technology of stator iron core and machine stator, which is applied to synchronous machine parts, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problem of limiting the power output of the traction machine and increasing the circumference of copper wire , temperature rise and other problems, to achieve the effect of improving material utilization, reducing the length of copper wire, and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

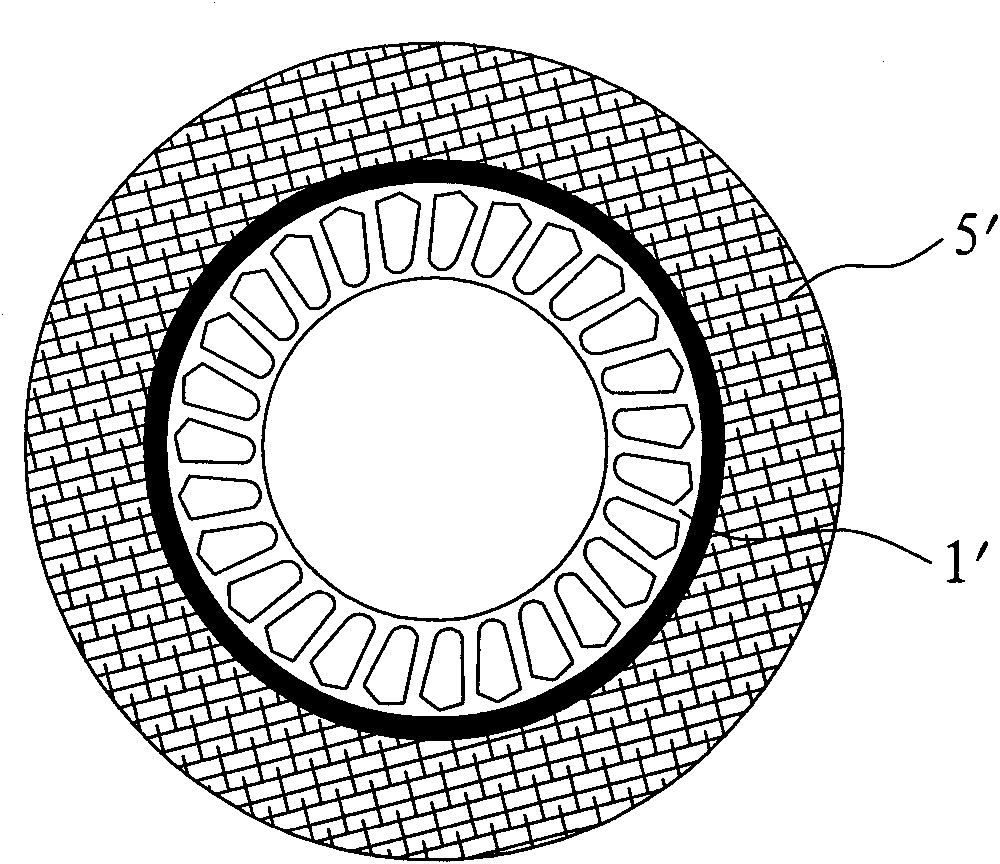

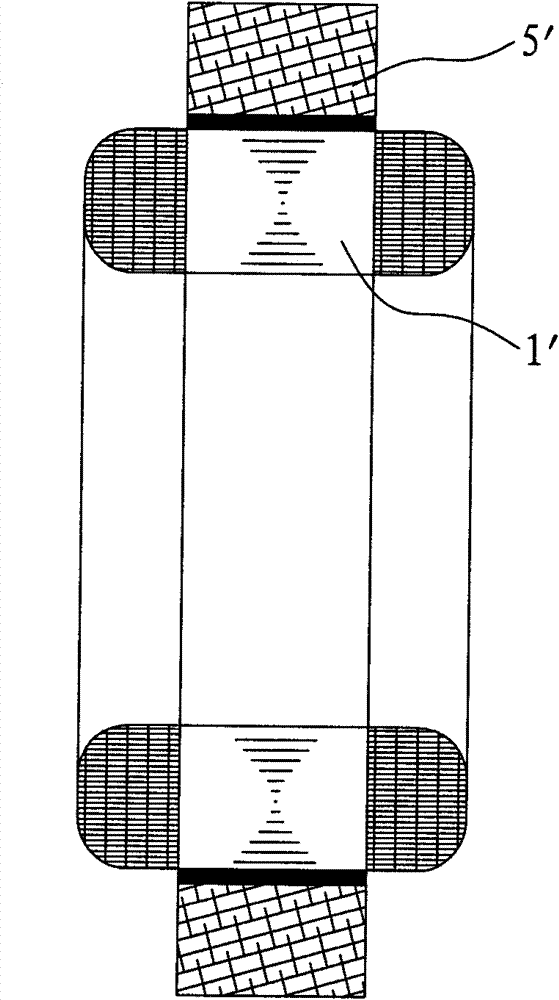

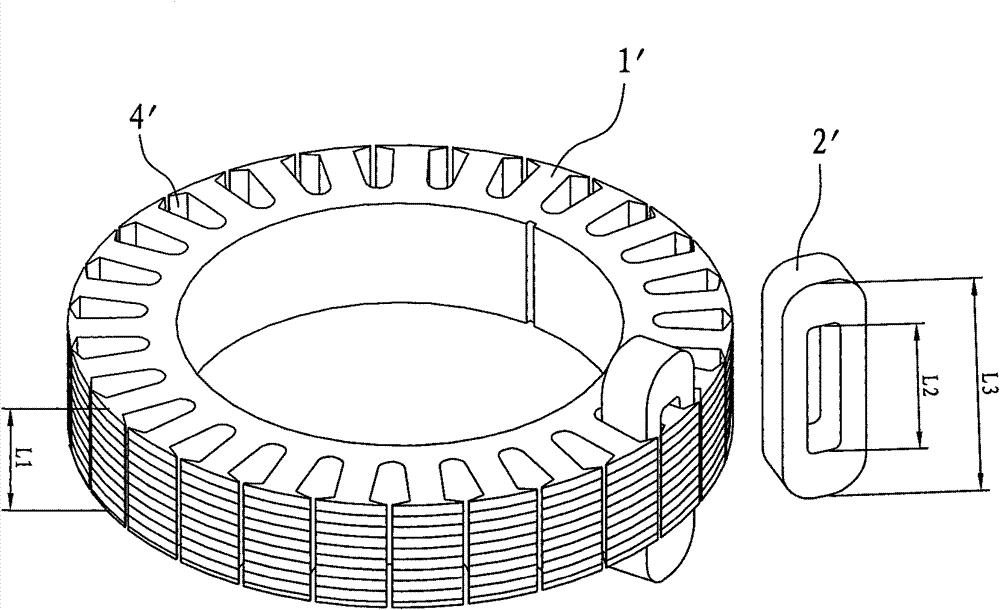

[0025] Such as Figure 5 --- Figure 7 As shown, a block-type traction machine stator core, the stator core 1 is composed of several separated stator blocks 2, and each separated stator block 2 is composed of multiple separated stator cores with the same outline 3 stacked and seen Figure 6 , a number of separate stator blocks 2 form a circular stator core with a certain thickness through a fixed structure (see Figure 11 ).

[0026] Each separated stator punching piece 3 is punched and formed by silicon steel sheet or other metal materials of standard thickness.

[0027] There is an interlocking structure between two adjacent separated stator punches 3, which is convenient for assembly and combination. Figure 9 : At A and B, the convex part of A is placed in the concave part of B to form as Figure 7 The interlocking structure shown is only one kind of embodiment.

[0028] The stator core 1 is composed of several separate stator blocks 2, such as Figure 10 Stator blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com