A track sound-absorbing panel and its installation and construction method

A construction method and technology of sound-absorbing panels, which are applied in the direction of track, track laying, track maintenance, etc., can solve problems such as replacement and maintenance of unfavorable track sound-absorbing panels, burial of train safety operation, and impact on train safety operation, so as to ensure safe operation and reduce Construction cost, effect of limiting displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

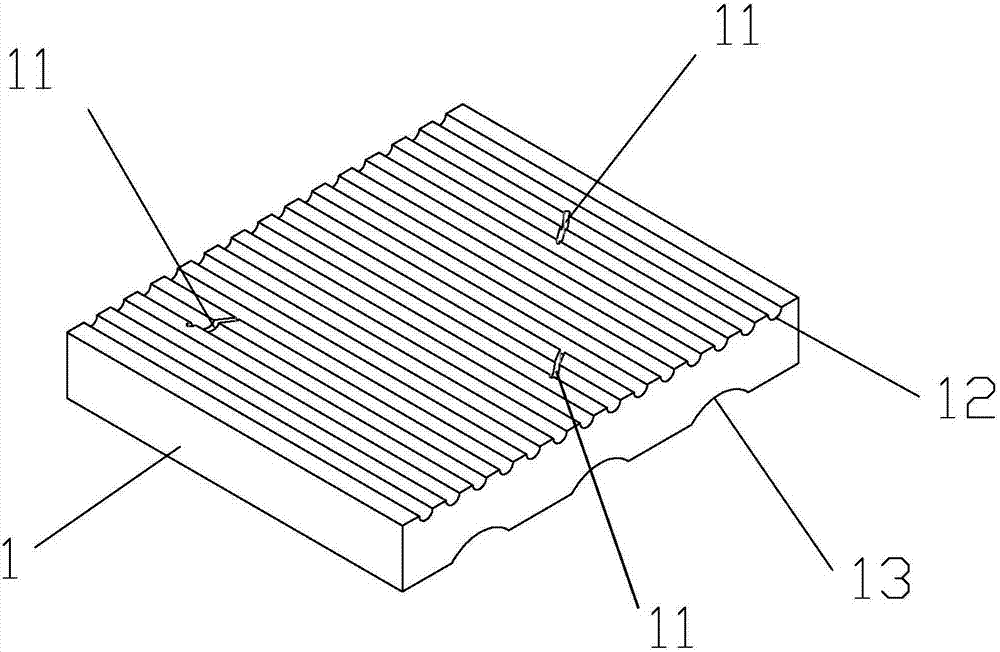

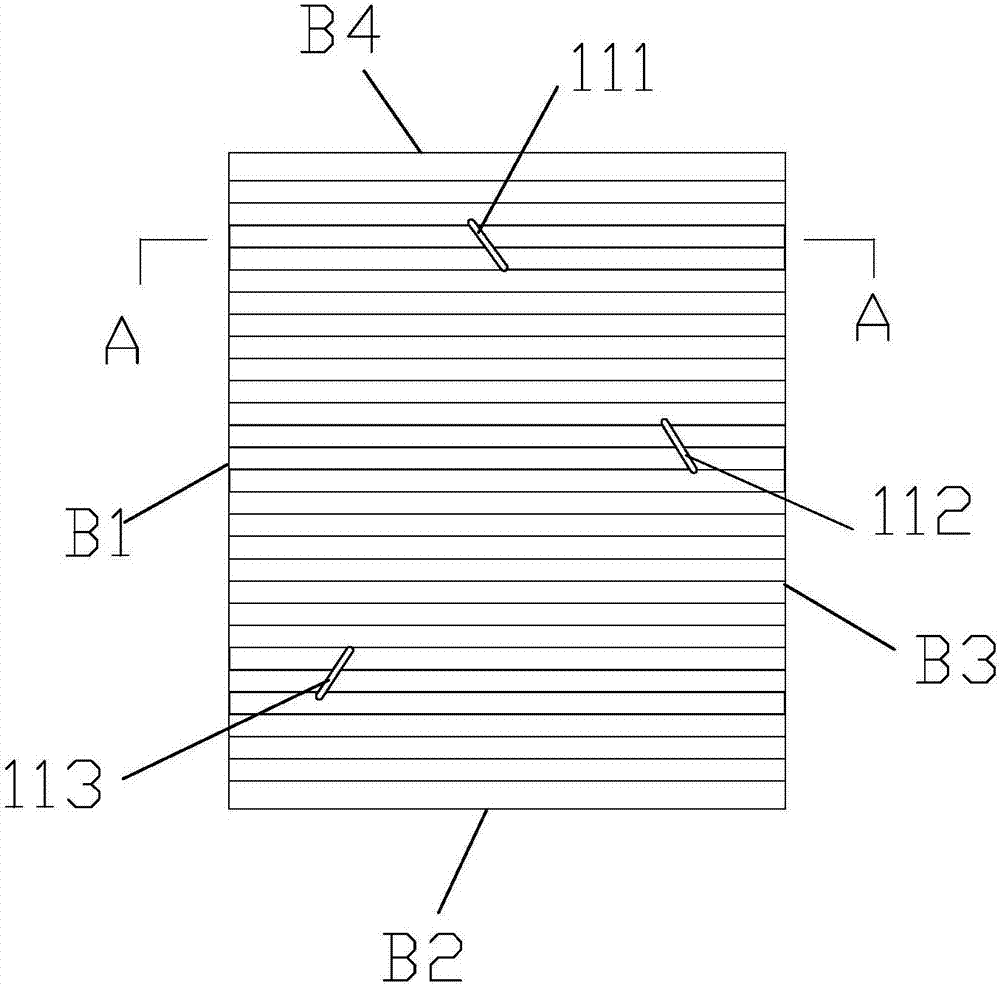

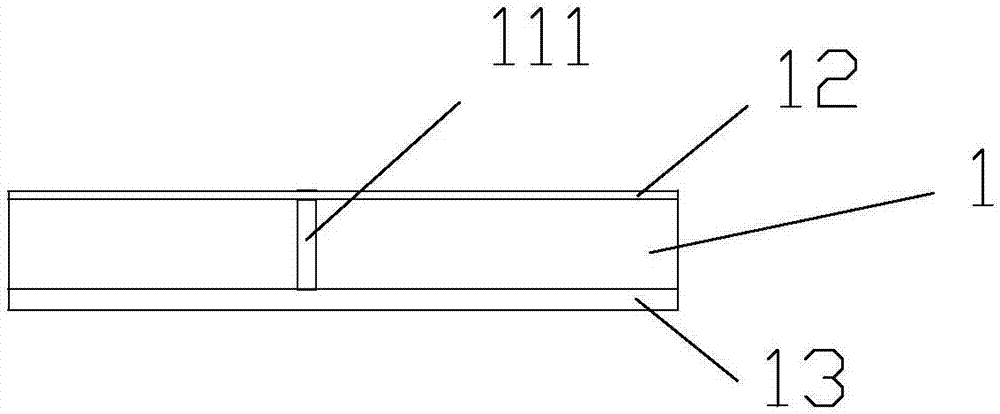

[0031] A track sound-absorbing panel such as Figure 1 to Figure 4 As shown, the track sound-absorbing panel 1 is a cuboid, the upper surface of the track sound-absorbing panel 1 is provided with a sound-absorbing groove 12, and the lower surface of the track sound-absorbing panel 1 is provided with an arc-shaped groove 13, and the sound-absorbing groove 12 and the arc-shaped groove 13 are mutually The purpose of the parallel and arc-shaped grooves is to facilitate the fixing of the sound-absorbing panels of the track, to prevent the unfixed sound-absorbing panels of the tracks from being repeatedly damaged by the vibration and wind rheology generated during the operation of the subway locomotive, and to ensure and improve safety; the sound-absorbing panels of the tracks are equipped with The elliptical track holes 11, the elliptical track holes 11 include elliptical track holes I 111, 112 and elliptical track holes II 113 in a triangular distribution; The middle of the adjace...

Embodiment 2

[0036] A method for installing and constructing a track sound-absorbing panel, the method for installing and constructing comprises the following steps:

[0037] A. Prefabricated track sound-absorbing panel 1:

[0038] The track sound-absorbing panel 1 with elliptical runway holes is prefabricated in the factory. The long axis of the elliptical runway through-hole forms an angle of 45° or 135° with any side line of the track sound-absorbing panel 1. The positions of the elliptical runway through holes I 111 and 112 are selected on the track. In the middle of the two adjacent sides of the sound-absorbing panel, the position of the elliptical runway through hole II 113 is selected on the diagonal line of the other two adjacent sides of the track sound-absorbing panel; after the maintenance of the track sound-absorbing panel 1 with the elliptical runway through hole reaches the design strength , after passing the quality inspection, it will be transported to the laying site;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com