Pile sinking construction method based on jacking-pushing walking platform

A construction method and a walking platform technology, which are applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as poor stability of floating platforms, fluctuations of floating platforms, time-consuming and labor-consuming auxiliary piles, etc., and achieve adjustment and movement The process is simple and convenient, the efficiency of pile driving is improved, and the operation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

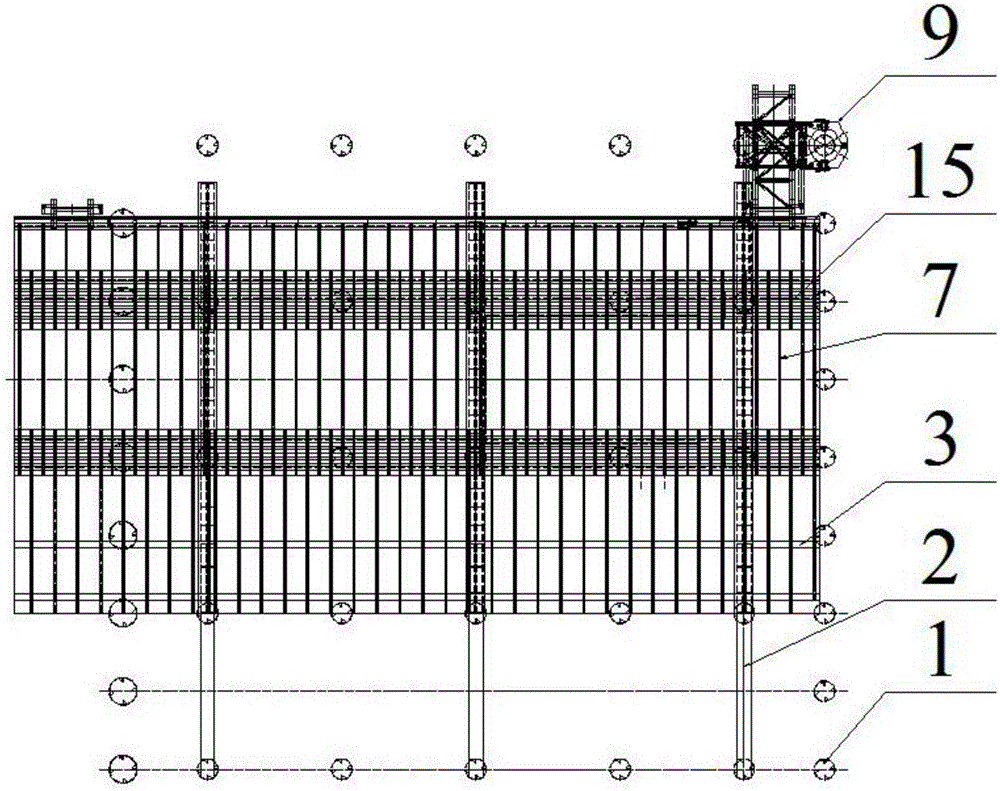

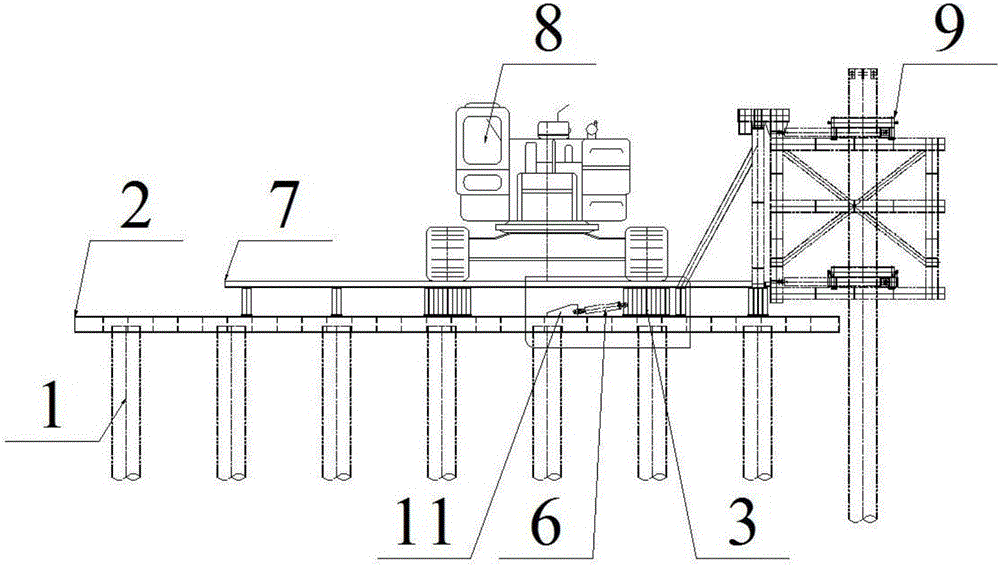

[0036] Such as Figure 1~5 , the walking platform of the present embodiment includes a crossbeam 3, and a distribution beam 7 is erected above the crossbeam 3, and the distribution beam 7 and the crossbeam 3 are arranged in a criss-cross pattern to form the supporting skeleton of the whole platform. As for the main structure, a guide frame 9 is installed on the side of the walking platform.

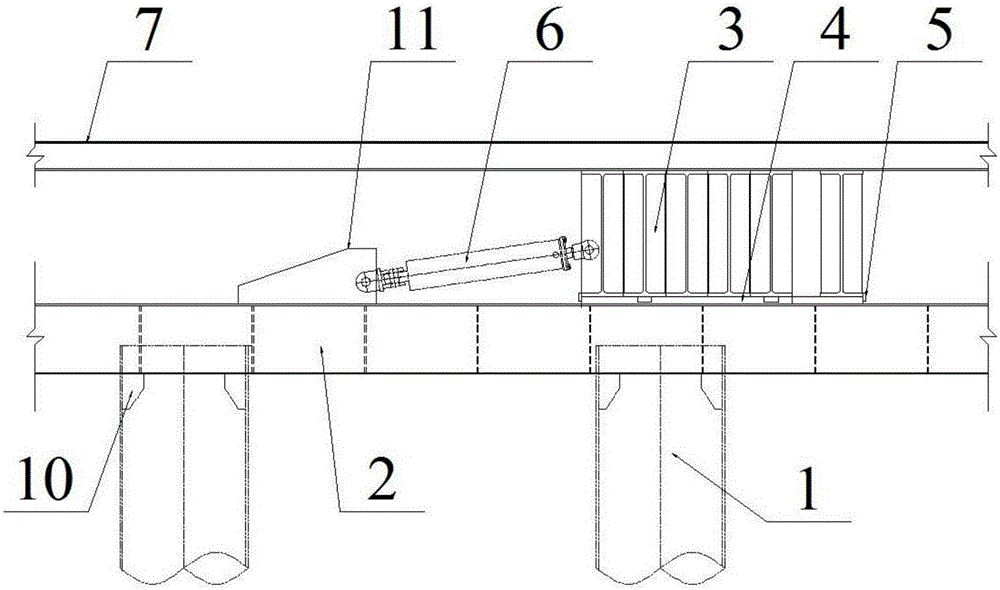

[0037] The walking platform of the present embodiment is slidably connected on the track beam 2 at the upper end of the steel pipe pile, as Figure 2-4 As shown, the track beam 2 of this embodiment is fixed on the upper end of the steel pipe pile 1. After the steel pipe pile 1 is installed, a fixing groove is opened on the upper end of the steel pipe pile 1, and the track beam 2 is engaged in the fixing groove. A stiffening plate 10 is welded b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com