A construction method for thermal insulation wall of steel structure building

A technology for building thermal insulation and construction methods, which is applied in the direction of construction, thermal insulation, and building components. It can solve the problems of reducing thermal insulation effect, cumbersome construction process, and increasing wall load, etc., to solve cold bridges, simplify construction technology, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention mainly discloses a construction method for the thermal insulation wall of a steel structure building, in which the relevant regulations on the construction technology of the steel structure and the energy-saving building thermal insulation are well known to those skilled in the relevant technical fields, so the following description does not refer to the building The use of thermal insulation templates and related regulations are fully described.

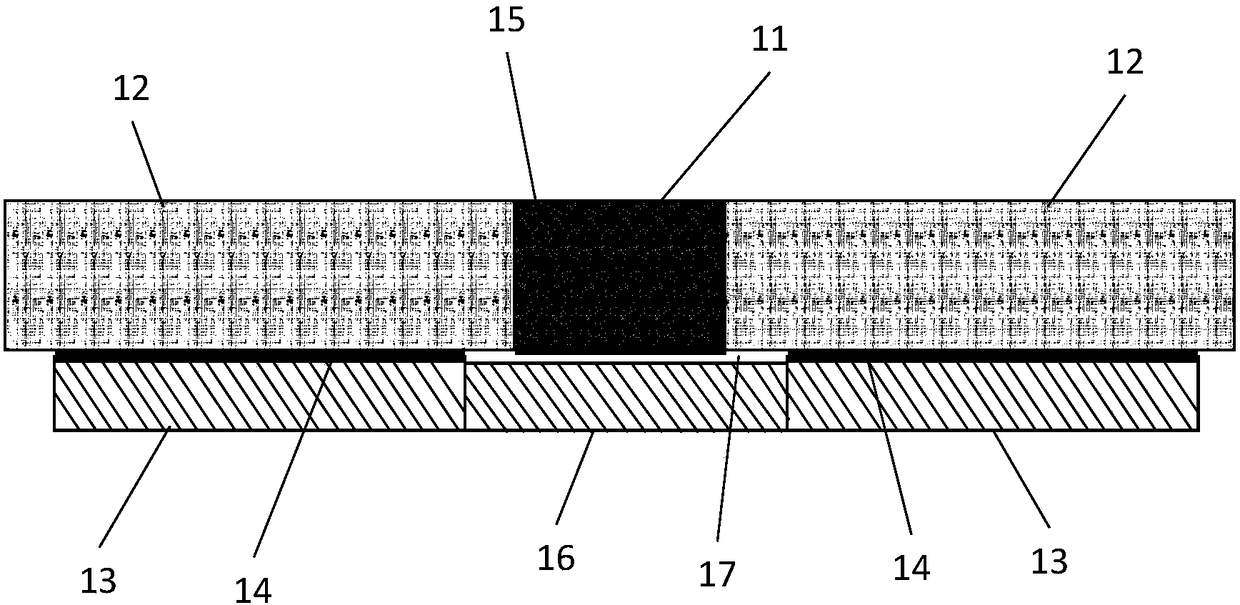

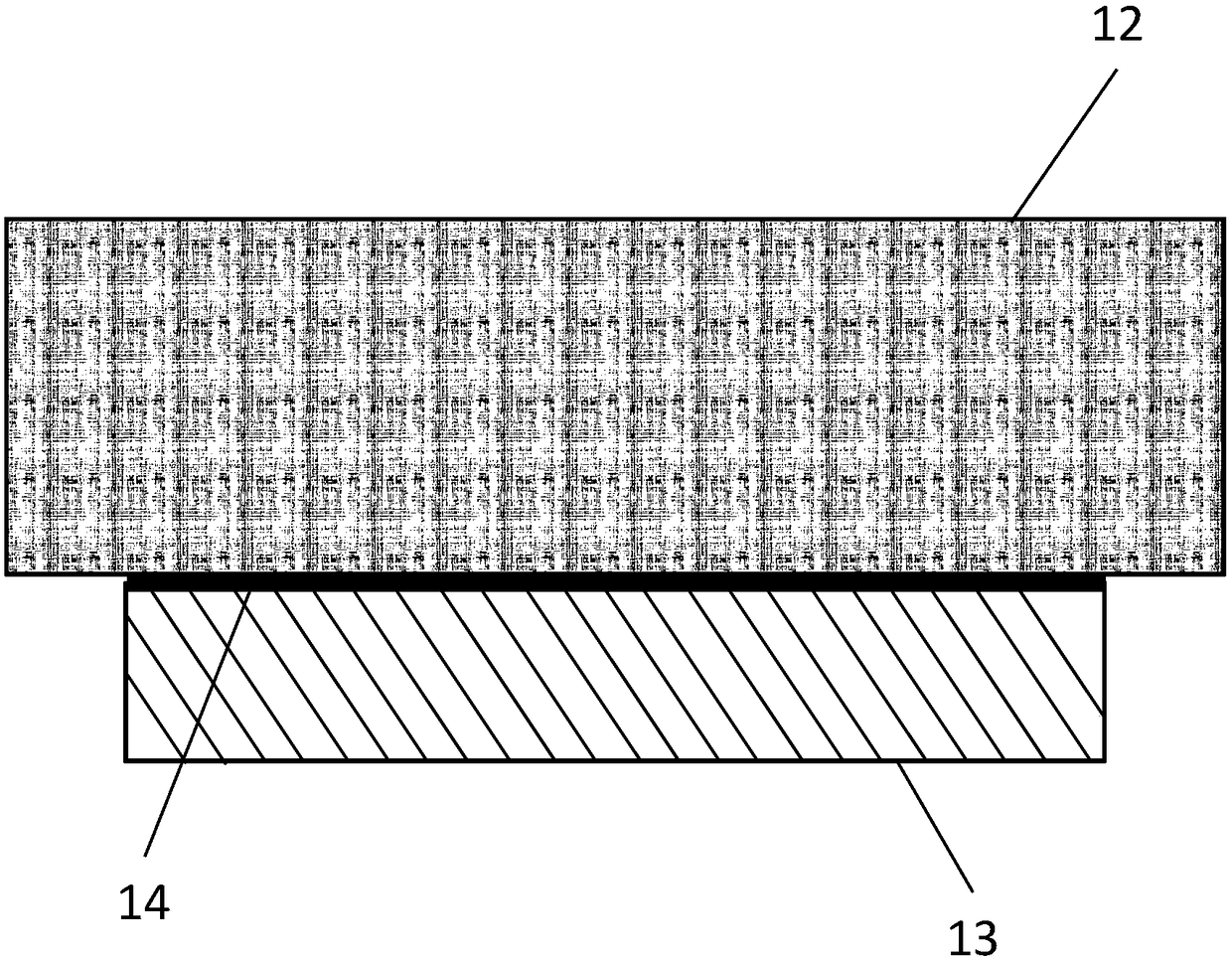

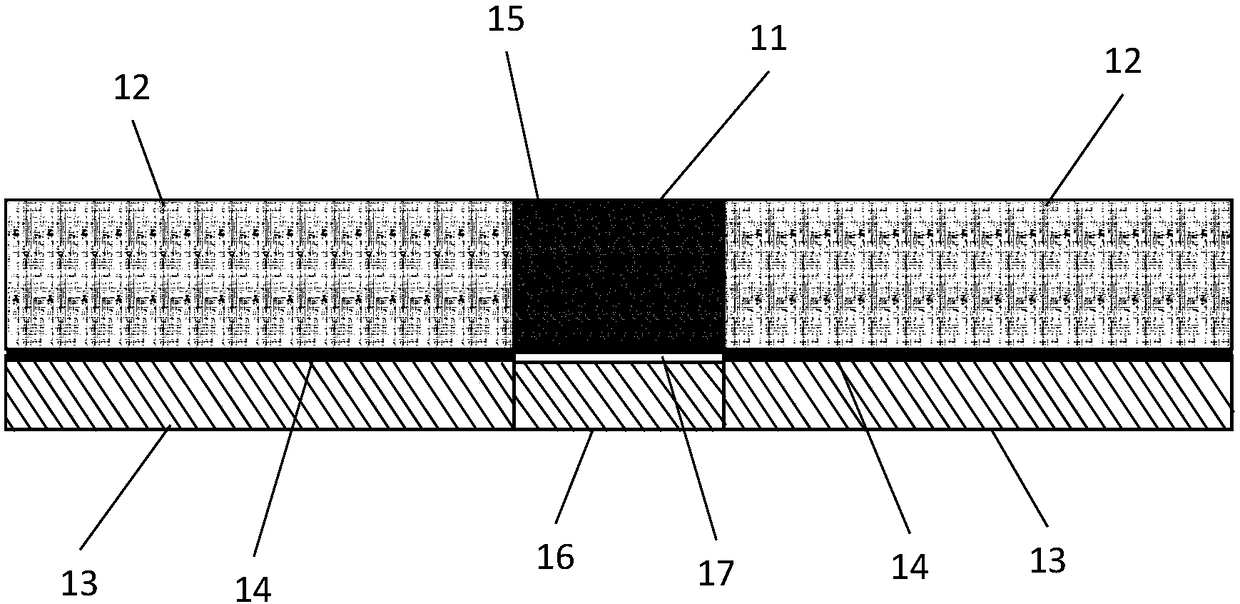

[0036] Please refer to figure 1 , to provide a steel structure building thermal insulation wall for the present invention, comprising steel column 11, wall body 12 and first thermal insulation board 13, first thermal insulation board 13 is arranged on the outer side of wall body 12, first thermal insulation board 13 and wall body There is an adhesive layer 14 between the 12, and the adhesive layer 14 can adopt inorganic mortar or fireproof adhesive, and the wall body 12 adopts the air-entrained concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com