A measurement and control production pipe string for stratified section mining

A technology for producing pipe strings and layered sections, which is applied in the production of fluids, drill pipes, casings, etc., can solve the problems of poor reliability of wet-slip connection of cables, lack of real-time control, and inability to know the ground, and achieve timely production conditions. Controllable, meet real-time monitoring requirements, simple and reliable effect of downhole operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

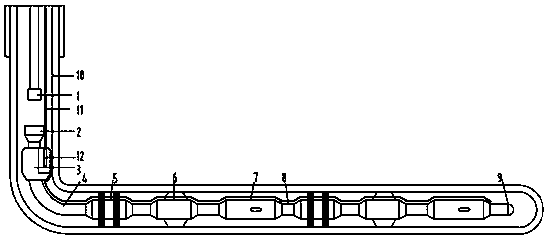

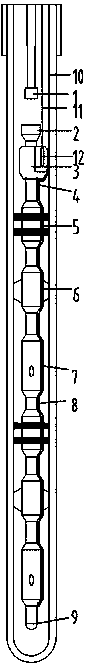

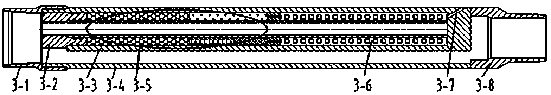

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings, not to limit the protection scope of the present invention, and all improvements obtained by using the design idea of the present invention belong to the protection scope of the present invention. The present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples.

[0024] see figure 1 , figure 2 , image 3 and Figure 4 , the intelligent real-time control device includes a centralized CPU management system 3-5 and a high-temperature-resistant high-energy battery 3-6, the body 3-4 is provided with an eccentric installation cavity 3-3, a centralized CPU management system 3-5 and a high-temperature resistant high-energy battery 3-6 6. Connect and install in the ring cavity between the eccentric installation cavity 3-3 and the inner center tube; one end of the eccentric installation cavity 3-3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com