Sublevel open stoping mining chassis route ore drawing subsequent filling mining method

A backfill mining method and mining approach technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problem of large mining workload and other problems, so as to ensure the quality of ore supply, high ore recovery rate, and saving mining standards. The effect of the amount of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

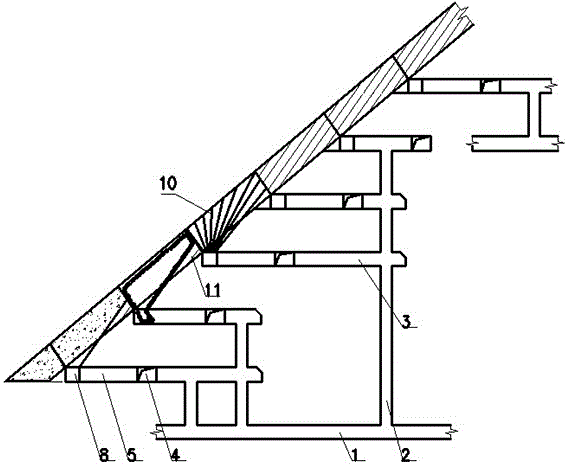

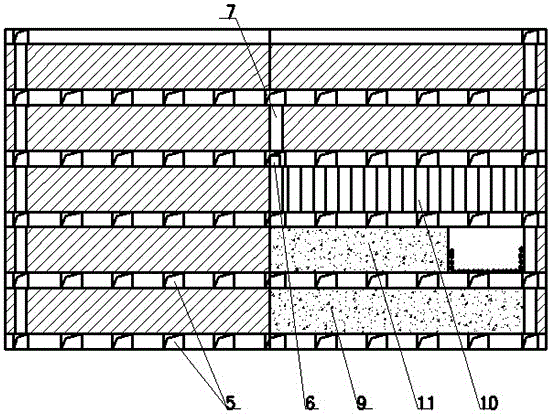

[0018] Depend on figure 1 , figure 2 As shown, the Ⅱ# ore body of an iron mine has a dip angle of 20°-60°, a thickness of 5-15 meters, and is distributed in a layered and stable manner, with a strike length of 1200m. The ore bodies within the scope belong to the type of iron ore deposits that are difficult to mine, and the surface of the iron ore deposits cannot be deformed and collapsed. According to the occurrence conditions of Ⅱ# ore body, combined with the preliminary mining design of the iron ore, a segmented open-field mining chassis of the present invention is selected to be used in the section north of the Ⅱ-1 exploration line in the middle section of -380m and the middle section of -320m. The filling mining method specifically includes the following steps:

[0019] Step A, ore block structure division: the ore block is arranged along the ore body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com