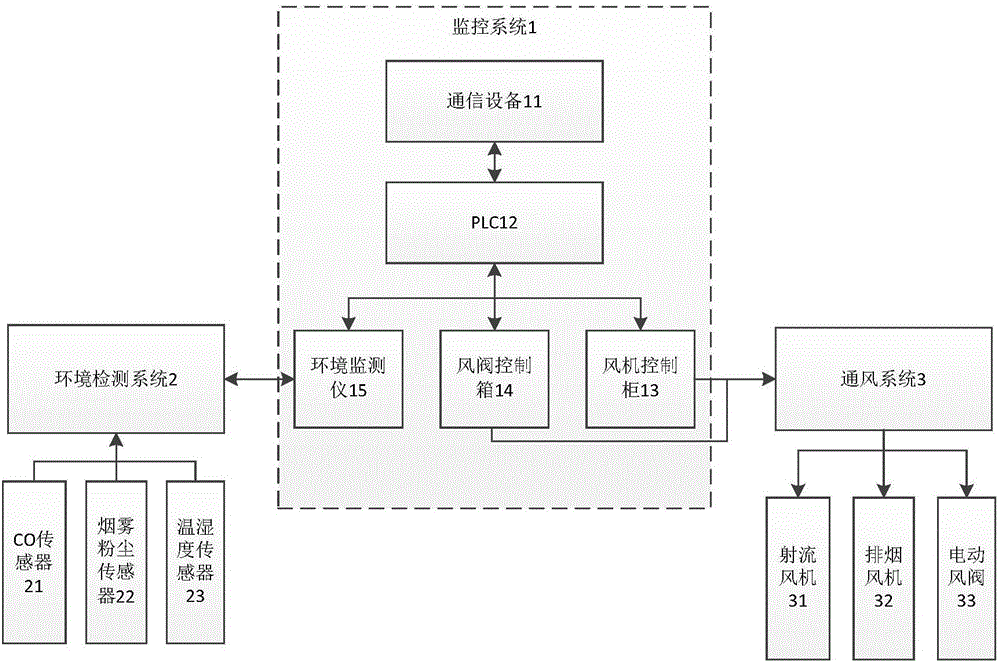

Intelligent ventilation monitoring system based on tunnel environment

A monitoring system and tunnel environment technology, which is applied in mine/tunnel ventilation, mining equipment, mining equipment, etc. It can solve the problems of no monitoring system, economic loss, and inability to timely lock dangerous positions, etc., and achieves simple structure and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: Under normal circumstances, according to the environmental parameters such as CO, dust that environmental detection system 2 collects, one or several jet fans 31 are automatically turned on and off by PLC12; according to the tunnel wind direction, the jet fans 31 are controlled to rotate forward and Reversed, to inhale fresh air into the tunnel, and at the same time, according to the working hours of the jet fans 31, the jet fans 31 are automatically controlled to start and stop in turn, so as to be used repeatedly, so as to avoid one or more jet fans 31 from starting and stopping too frequently, which may cause the jet fans 31 to fail. The service life is shortened; when the train passes through the tunnel or stops in the tunnel, the ventilation system 3 is automatically opened, and when the train leaves the tunnel, the ventilation system 3 is automatically closed to save electric energy.

Embodiment 2

[0014] Embodiment 2: When a fire occurs, PLC12 controls all the exhaust fans 32 to perform smoke exhaust work, and the smoke exhaust direction is along the direction of the tunnel; for extra-long tunnels, it is controlled according to the predetermined disaster plan; all jet fans 31 are turned on during the fire extinguishing stage And smoke exhaust fan 32, increase air volume, to be beneficial to extinguishing a fire, cooling and smoke exhaust. After the fire extinguishing, the fan is gradually turned off by the PLC12 or the on-site control cabinet. After confirming that it can pass normally, the original setting of various equipment operating states will be restored.

Embodiment 3

[0015] Embodiment 3: When a certain equipment of the ventilation system 3 breaks down and cannot continue to operate, the PLC12 will automatically switch to the standby equipment, and at the same time send an alarm signal to notify the maintenance personnel to detect, in order to prevent a wider range of equipment failures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com