Pressure gas pipeline leakage detection system and method

A pressure gas and pipeline leakage technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of poor location and accuracy of leakage points, achieve high accuracy and ensure real-time detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

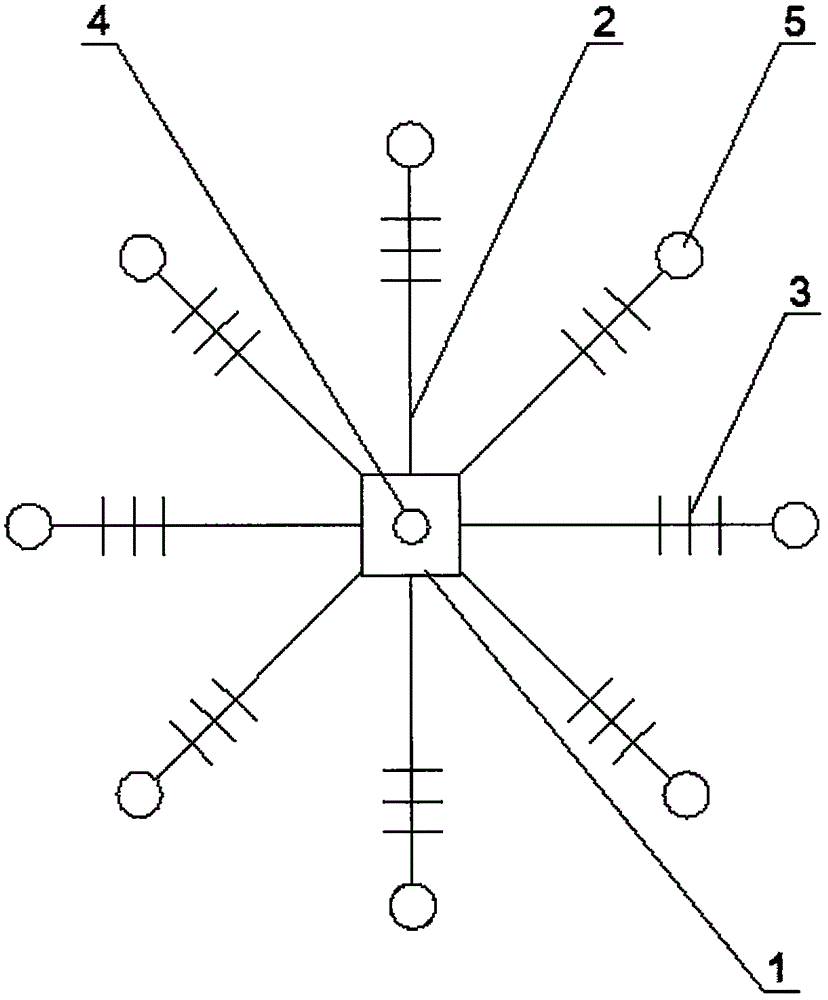

[0027] The pressure gas pipeline leakage detection system includes a hub 1, 6 spoke fingers 2, 6 sensing units 3, a positioning unit 4, 6 fingers 5 and a console.

[0028] The core 1 moves in the pipeline with the pressure gas. The center 1 is equipped with fluid dynamics software CFD, and according to the pressure data collected by the sensing unit 3, the pressure gradient distribution data inside the pressure gas pipeline is automatically generated, and according to the preset pressure gradient change critical value, it is confirmed whether the gas pressure pipeline is Leakage, in the event of a confirmed pipeline leak, an alert is sent to the console.

[0029] One end of the spoke fingers 2 is fixedly connected to the central hub 1 for moving the central hub 1 in the pipeline with the pressure gas, and the six spoke fingers 2 are symmetrically distributed around the center of the central hub 1 .

[0030] Each of the sensing units 3 is installed on one of the spoke fingers ...

Embodiment 2

[0035] Compared with the second embodiment, this embodiment has the same technical features except for the following differences.

[0036] The hub 1 is used to analyze and process the data collected by the sensing unit 3 to form real-time pressure data, and transmit the pressure data to the console.

[0037] The console is equipped with fluid dynamics software CFD, which generates a pressure gradient distribution map inside the pressure gas pipeline according to the pressure data transmitted by the center 1, and determines whether the pipeline leaks according to the preset pressure gradient change critical value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com