Indoor harmful gas removing device based on low-temperature cold source

A low-temperature cold source, harmful gas technology, used in indoor harmful gas removal devices, harmful gas purification fields, can solve the problems of limited purification effect, secondary pollution, etc., to achieve safe discharge, convenient secondary pollution, and no secondary pollution. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

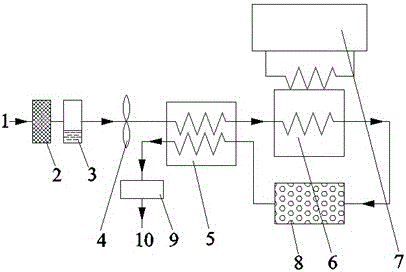

[0024] Such as figure 1 As shown, an indoor harmful gas removal device based on a low-temperature cold source includes a primary heat exchanger 5, a secondary heat exchanger 6, an adsorber 8, a low-temperature cold source 7, an air inlet 1 and a primary heat exchanger 5 The gas inlet of the primary heat exchanger 5 is connected with the gas inlet of the secondary heat exchanger 6, and the gas outlet of the secondary heat exchanger 6 is connected with the gas inlet of the primary adsorber 8. The gas outlet of the primary adsorber 8 is connected to the cold end inlet of the primary heat exchanger 5, the cold end outlet of the primary heat exchanger 5 is connected to the air outlet 10, and the low-temperature cold source 7 is connected to the secondary heat exchanger 6 phase connection.

[0025] Between the air inlet 1 and the primary heat exchanger 5, a filter screen 2, a dehumidification device 3, and a fan 4 are sequentially arranged, and a humidifier 9 is arranged between th...

Embodiment 2

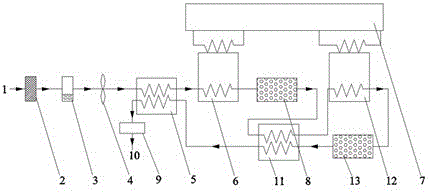

[0029] In order to obtain air with a higher degree of cleanliness, this embodiment adopts a combination of multi-stage heat exchangers and adsorbers.

[0030] In this embodiment, the first-stage heat exchanger 5 and the third-stage heat exchanger 11 adopt plate-fin heat exchangers, the second-stage heat exchanger 6 and the fourth-stage heat exchanger 12 adopt finned heat exchangers, and the first-stage adsorber The adsorbent used in 8 is molecular sieve, the adsorbent used in the secondary adsorber 13 is activated carbon, and the low-temperature cold source 7 is a refrigerator.

[0031] Such as figure 2 As shown, the secondary heat exchanger 6 and the fourth-stage heat exchanger 12 of an indoor harmful gas removal device based on a low-temperature cold source are connected to the low-temperature cold source 7 respectively, and the air inlet 1 is connected to the gas of the primary heat exchanger 5 The inlets are connected, the gas outlet of the primary heat exchanger 5 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com