Evaporation condensation oilless air conditioning system and control method thereof

A technology for evaporative condensation and air-conditioning systems, which is applied in air-conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc. It can solve problems such as energy efficiency decline, cooling tower occupancy, and equipment complexity, so as to improve energy efficiency and increase evaporation temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

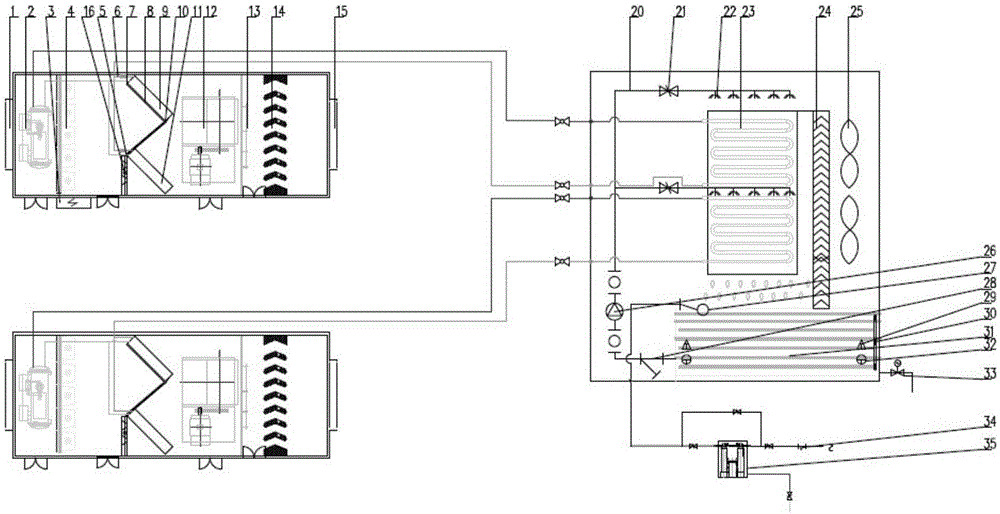

[0040] Such as figure 1 As shown, it is a structural schematic diagram of a specific embodiment of an evaporative condensation oil-free air-conditioning system according to the present invention. see figure 1 In this specific embodiment, an evaporative condensation oil-free air conditioning system specifically includes a control device 3, an air duct, an evaporative condensation cooling device connected to the control device 3, and a direct expansion compressed air processing device; air inlet ports are respectively provided at both ends of the air duct 1 and the air supply interface 15, the direct expansion compressed air processing device is placed in the air duct and is located between the air inlet interface 1 and the air supply interface 15, and the air supply interface 15 is used to communicate with the cooling area;

[0041] The direct expansion compressed air treatment device includes a magnetic levitation frequency conversion centrifugal compressor 2 connected to the...

Embodiment 2

[0061] On the basis of the evaporative-condensation oil-free air-conditioning system in Embodiment 1, the present invention also provides a control method for the evaporative-condensation oil-free air-conditioner system. This control method is implemented based on the air conditioning system of Embodiment 1. Described control method is specifically:

[0062] Open the control device 3, the air filter device 4, the air power system 12, the water pump 26, the fan 25, the damper 8 is at the air-conditioning operation limit end 5 driven by the damper drive shaft 10, and the damper 16 is in an open state;

[0063] When the control device 3 detects that the temperature in the cooling area has a logical relationship T 0 0 +Δt 1 , the air valve 16 is closed, the magnetic levitation frequency conversion centrifugal compressor 2 is opened and press H 1 / 2 frequency of operation, where T 0 is the set value of the cooling area, T is the real-time detection value of the cooling area, Δt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com