Novel light body armor with kinetic energy absorption structure

A technology of absorbing structure and bulletproof vest, which is applied in the technical field of cushioning structure of bulletproof clothing. It can solve the problems of low elastic deformation of the foam layer, self-recovery, and flexible movement restrictions, so as to reduce injuries, save maintenance and storage costs, etc. , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

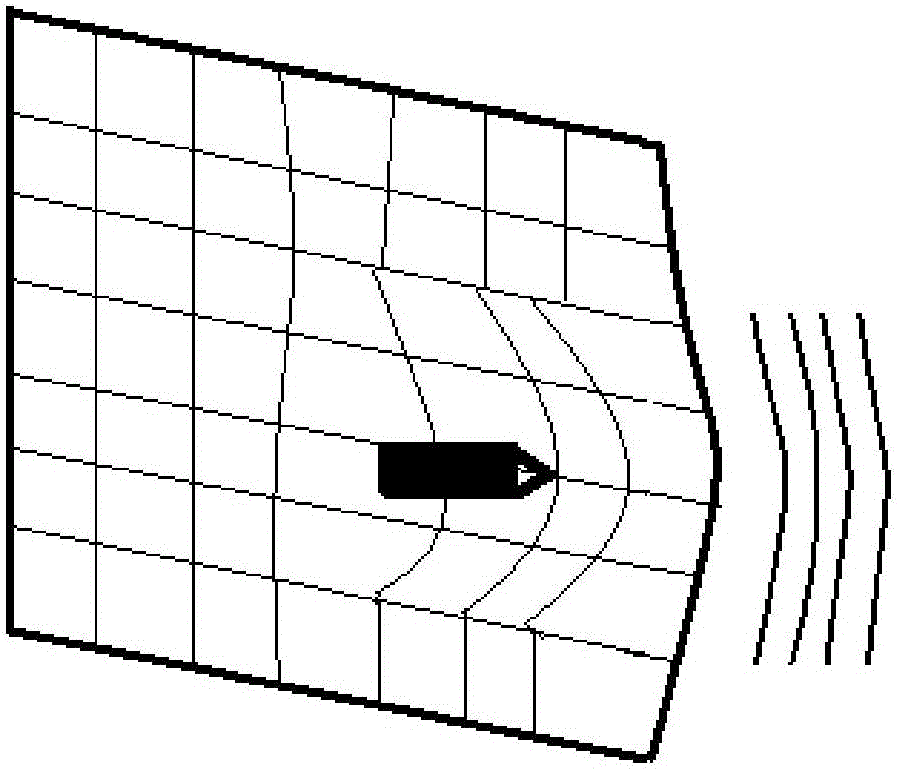

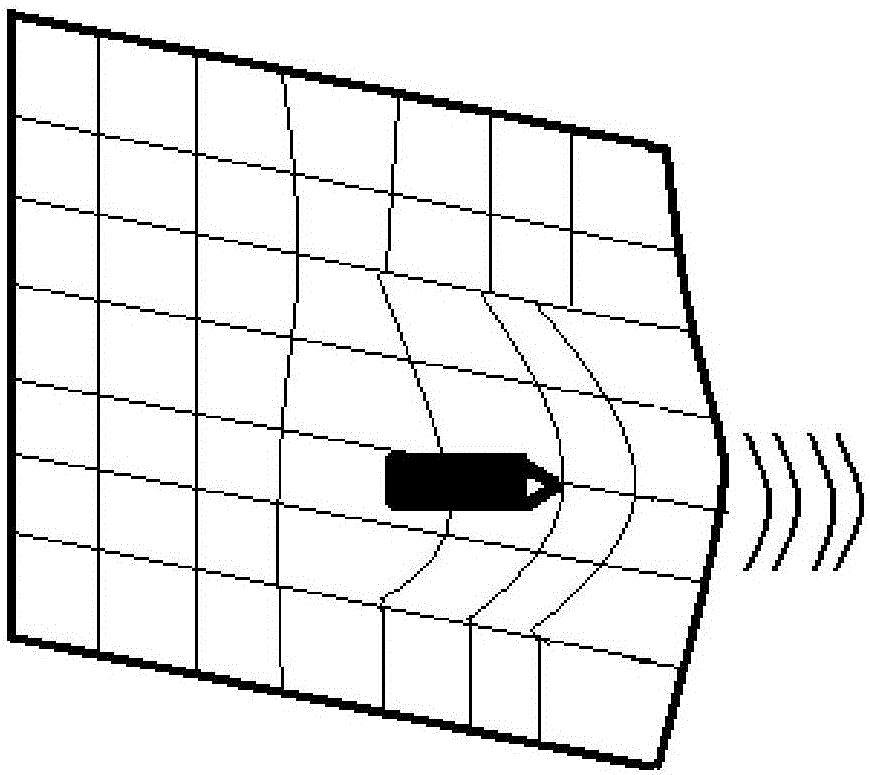

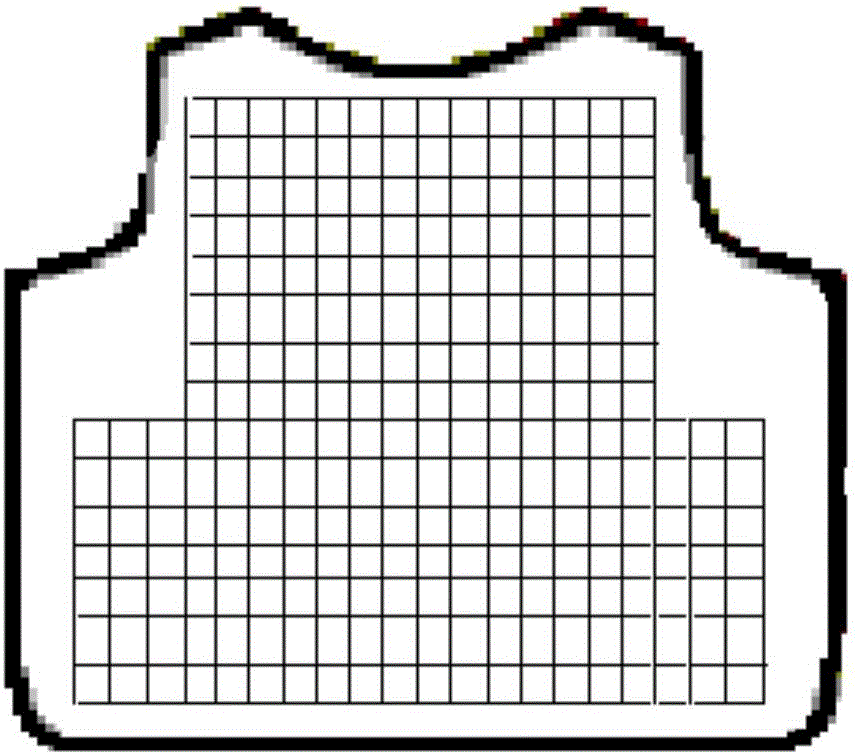

[0036] refer to Figure 1 to Figure 3 As shown, a new type of lightweight body armor with a kinetic energy absorption structure, including: jacket, body armor body, inner lining and kinetic energy absorption structure;

[0037] Further, the jacket is placed on the outside of the body armor body for aesthetic and protective purposes;

[0038] Further, the inner lining is placed on the inner side of the bulletproof vest body, which is used to protect the human body and look beautiful;

[0039] Further, the body armor body is made of high-performance fibers;

[0040] As an example, the high-performance fiber is one or a combination of ultra-high molecular weight polyethylene, aramid fiber, PBO or carbon fiber materials;

[0041] As an illustration, the specified areal density (i.e. single-layer density) of its ultra-high molecular weight poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com