Suspension device for tunnels

A technology for suspension devices and tunnels, which is applied to mining devices, mining equipment, earthwork drilling and mining, etc. It can solve the problems of affecting the service life, not being able to increase or decrease the specifications of the pre-buried channels, and being fixed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

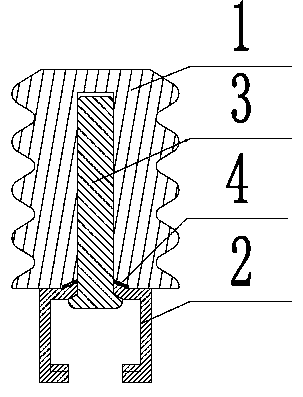

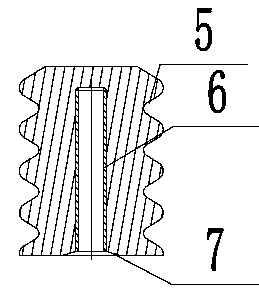

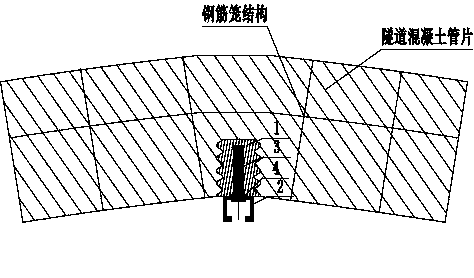

[0013] The following describes in detail a specific implementation example of the new type of the present invention, see image 3 , A suspension device for a tunnel is composed of embedded casing 1, toothed channel 2, countersunk screws 3, and elastic gasket 4. During construction, the embedded casing 1 is pre-cast in the tunnel concrete segments, and the cast The position is in the gap of the concrete segment reinforcement cage of the tunnel, the toothed channel 2 is connected to the inner arc surface of the tunnel concrete segment by the tightening fit of the countersunk screw 3 and the embedded casing 1, avoiding the embedded casing, The toothed channel is in direct contact with the steel cage structure in the tunnel concrete segment. The embedded casing 1 occupies a small space in the tunnel concrete segment and has little impact on the main structure of the tunnel concrete segment. The countersunk screw 3 An elastic washer 4 is installed between the bottom and the bottom 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com