A combined length measuring device embedded in the inner cone and inner hole of the inner end of the cylindrical gear opposite to each other

A cylindrical gear, length measurement technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of structural asymmetry, shaking, the angle of the cone surface must be precisely controlled, and achieve accurate and smooth transmission and rapid measurement, tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

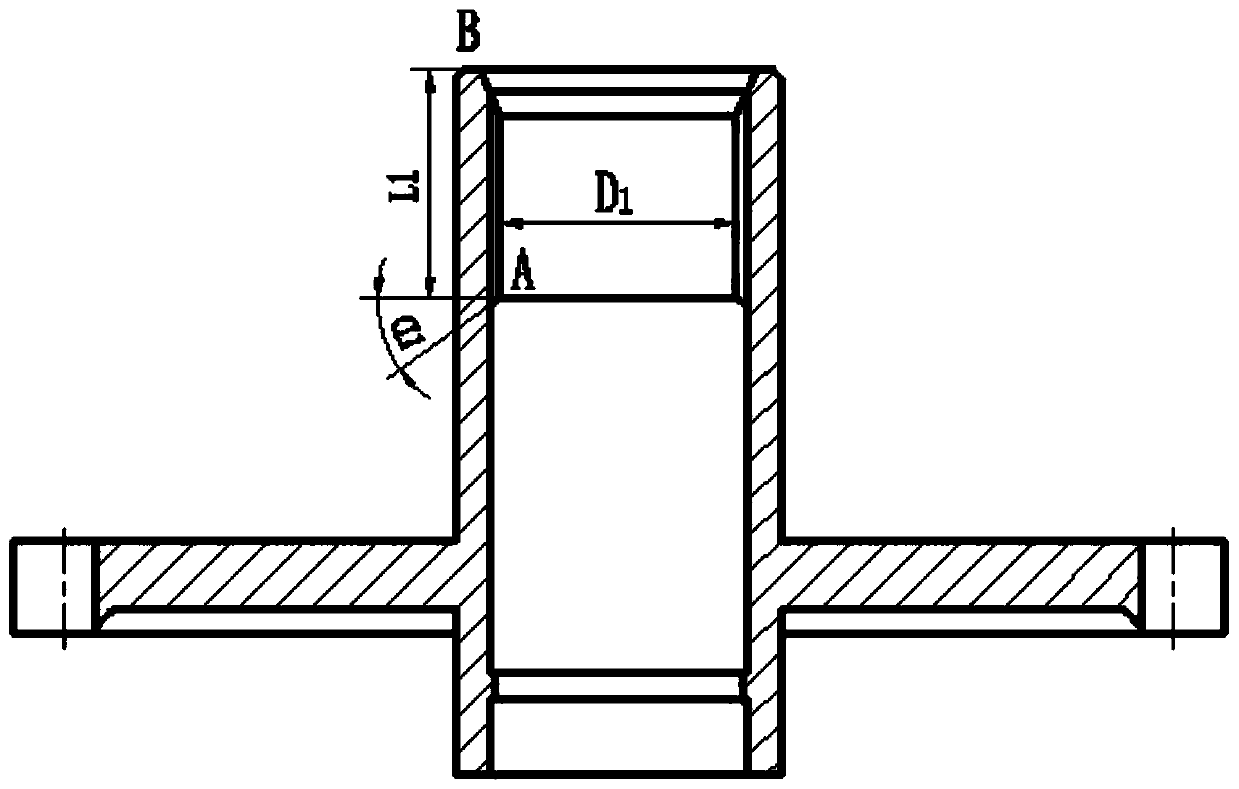

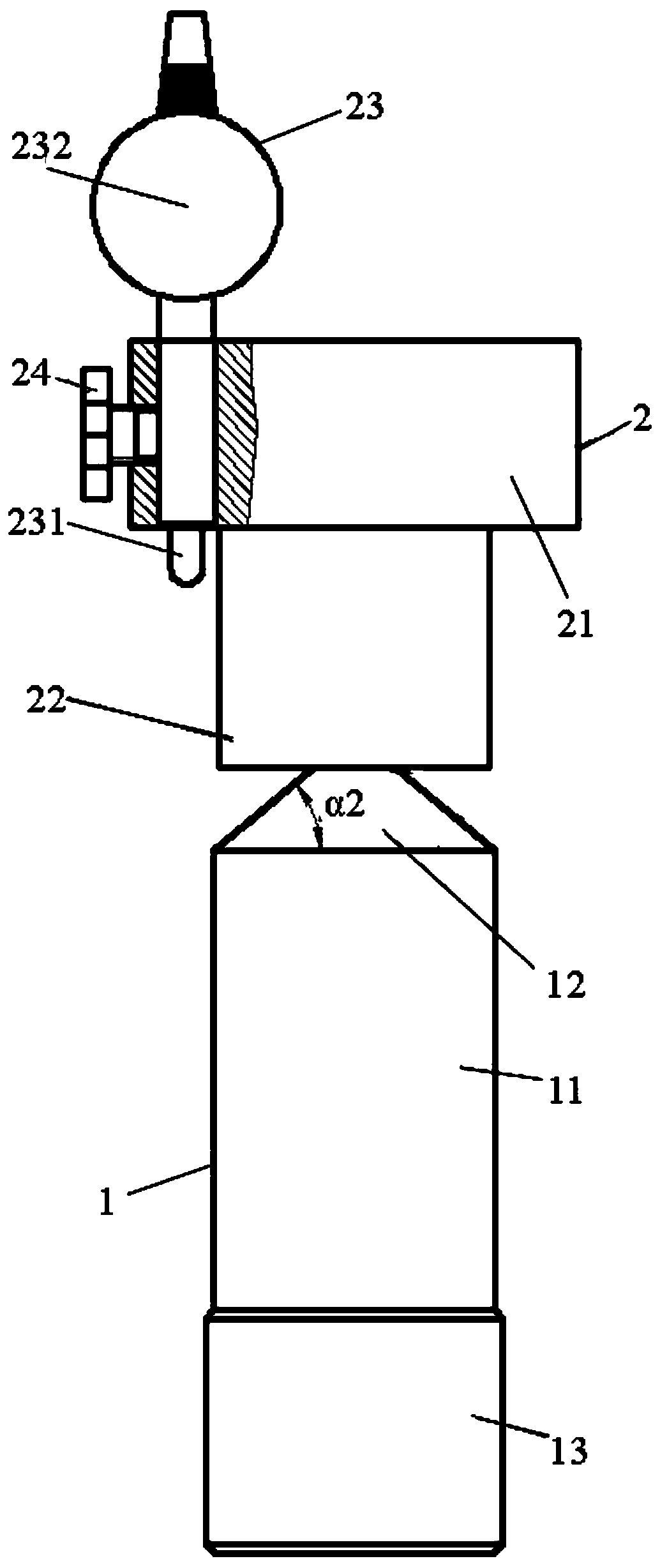

[0026] see figure 2 , the present invention provides a combined length measuring device that is embedded in the inner taper hole of the inner end of the cylindrical gear, which is composed of a separate positioning plug rod 1 and a measuring plug rod 2 that are separately arranged. In order to realize the measurement and positioning functions, the outer diameters of the positioning plug rod 1 and the measuring plug rod 2 in this embodiment are both smaller than the inner diameter of the measured inner hole. During measurement, the positioning stopper rod 1 and the measuring stopper rod 2 extend into the measured inner hole from the openings at both ends of the measured inner hole respectively.

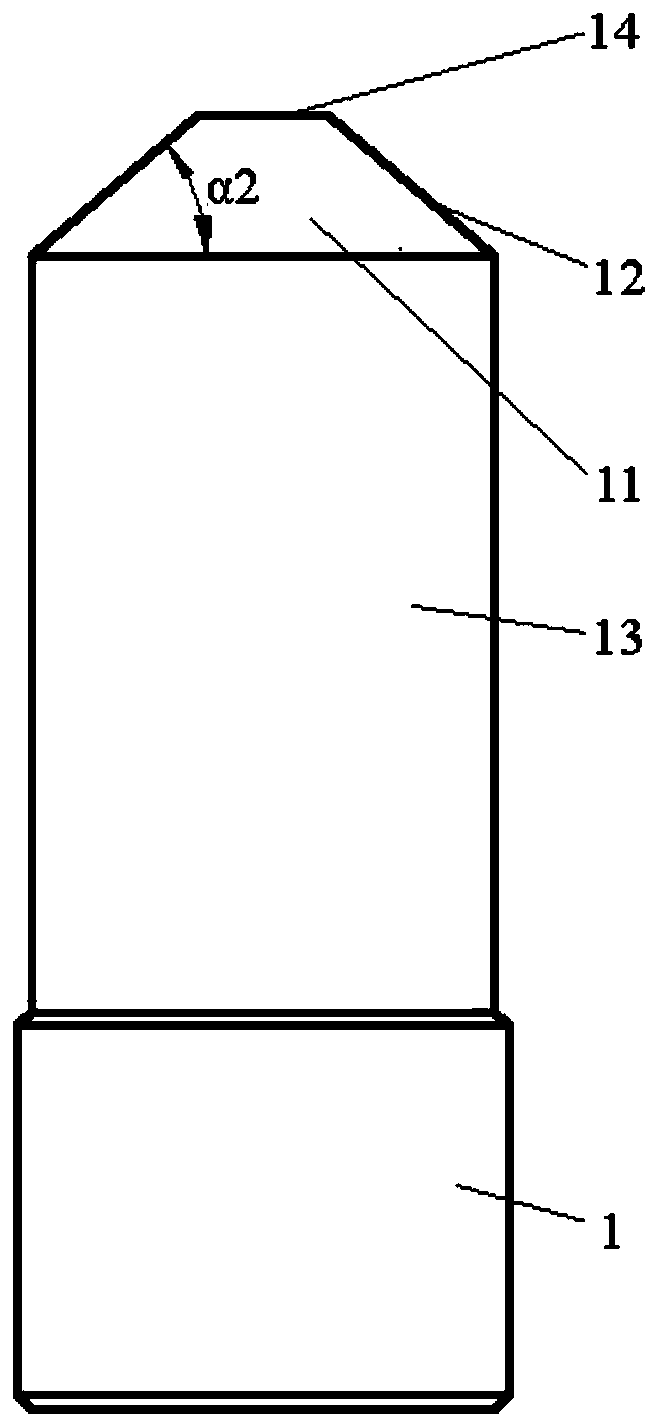

[0027] see figure 2 and image 3Specifically, the positioning plug rod 1 is used to locate the measurement starting point of the inner hole, that is, the measurement starting point at the inner end inner cone of the small hole used to locate the inner cone at both ends of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com