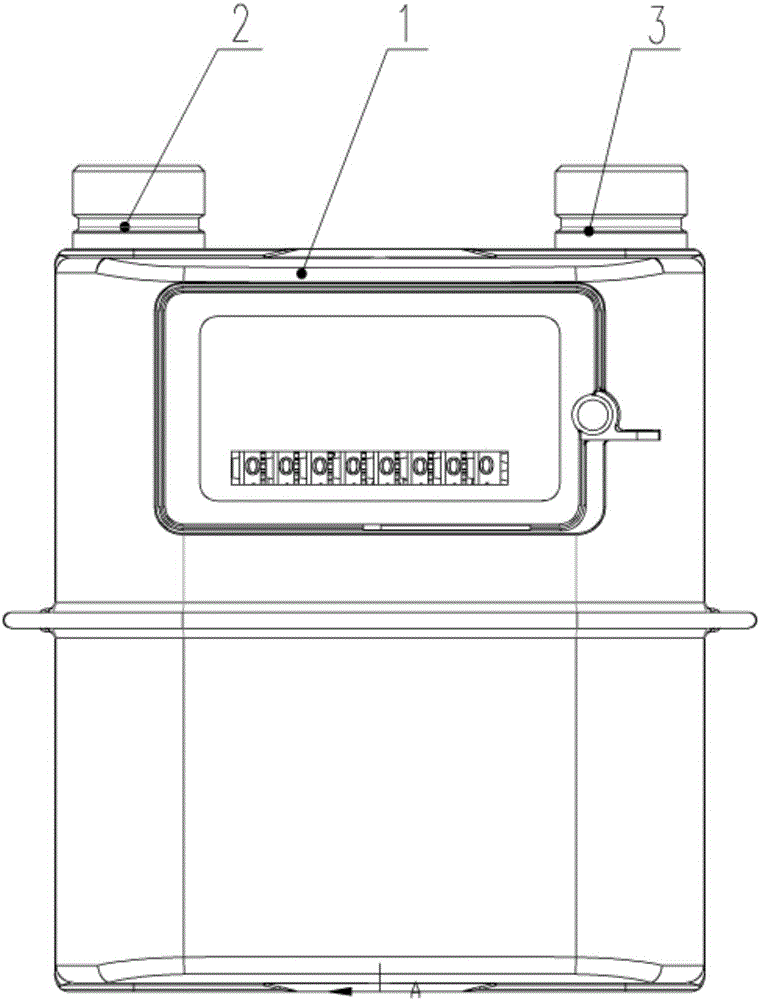

G2.5 diaphragm gas meter

A membrane gas meter and gas inlet technology, applied in instruments, measuring devices, volume metering, etc., can solve the problems of poor matching of flow channels, aging structure, large pressure loss, etc., and reduce the cost of parts, assembly and testing costs , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

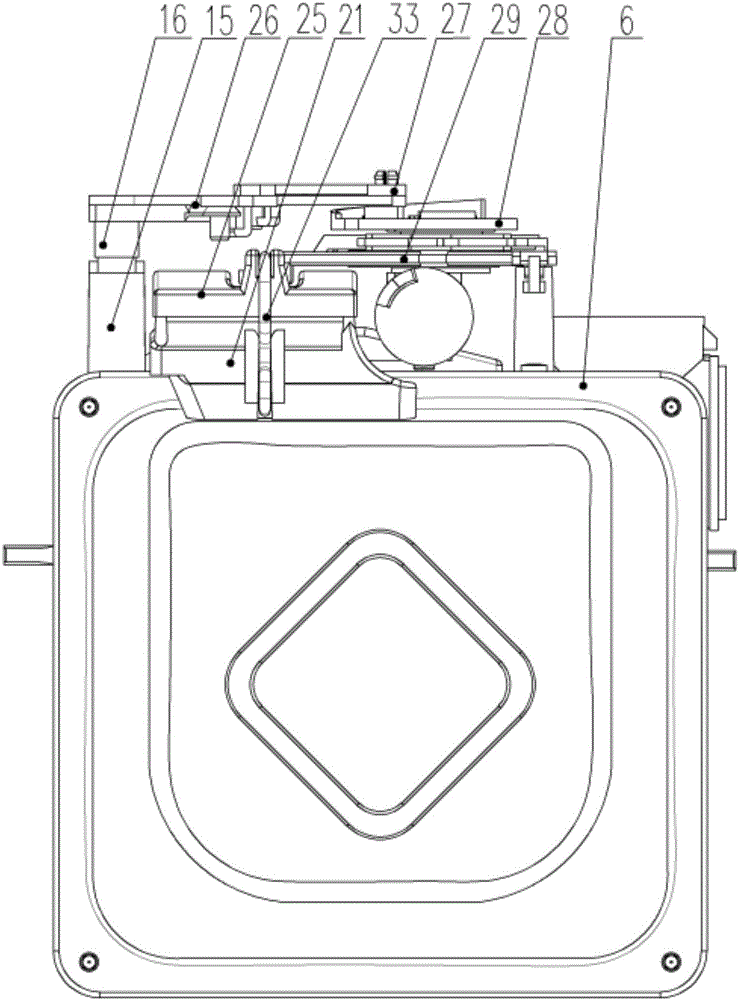

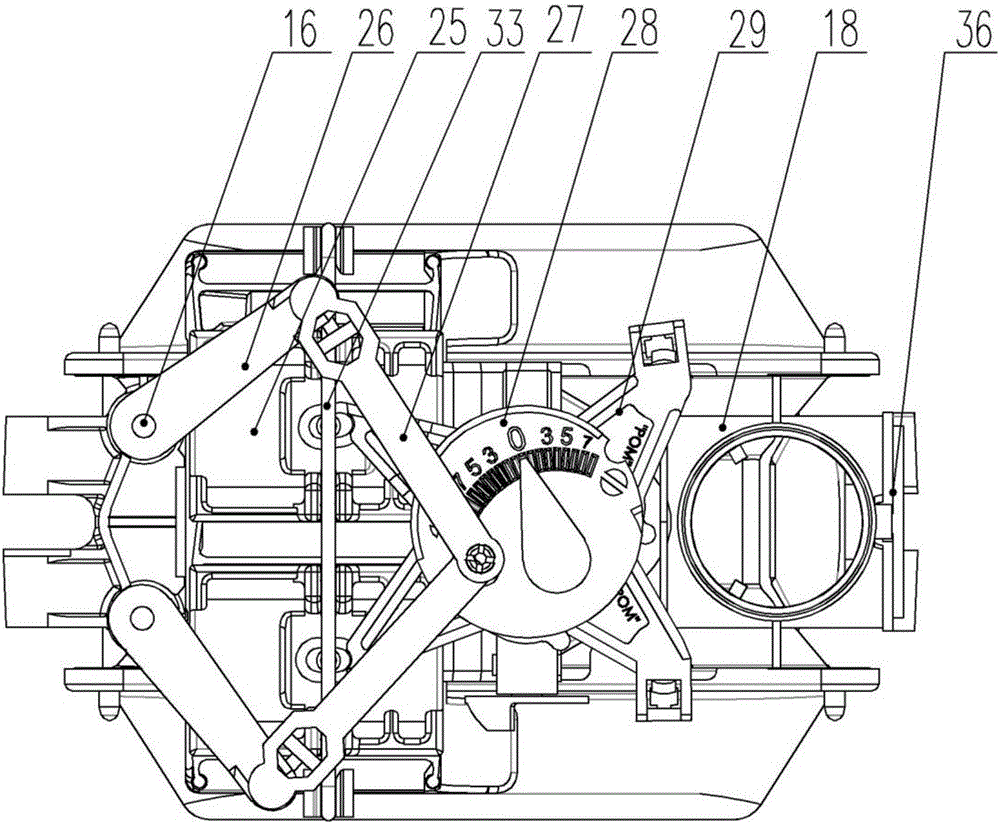

[0028] Refer to attached figure 1 , 2 , 3, 4, 5, the present invention comprises installation housing 1, and gas inlet 2 and gas outlet 3 are arranged on installation housing 1, and movement is installed in installation housing 1, and movement comprises movement body 6, the first measurement Shell 4 and the second metering shell 5, the core body 6 is provided with the first membrane box 7 and the second membrane box 8, the first membrane box 7 and the first metering shell 4, the second membrane box 8 and the second metering shell 5 constitute the first chamber and the second chamber respectively, and the first membrane 34 and the second membrane are respectively provided between the first membrane box 7 and the first metering shell 4, the second membrane box 8 and the second metering shell 5 35, and the first film 34 separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com