A method for testing optical fiber stress and strain

A technology of strain testing and optical fiber stress, which is applied in the field of optical fiber production, can solve problems such as low input cost and test deviation, and achieve the effects of reduced input cost, convenient use, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

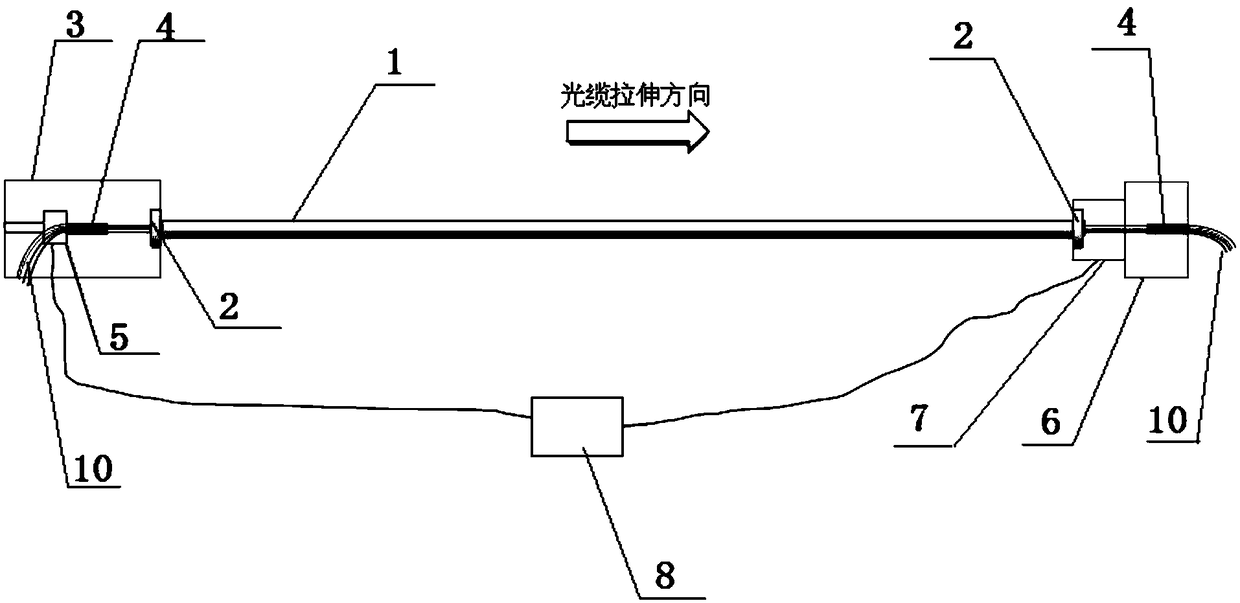

[0028] To carry out optical fiber stress and strain test on the optical cable, first fix the optical cable on the test device, such as figure 2 As shown in , the specific steps are as follows:

[0029] Step 1: Strip off the two ends of the submarine optical cable 1 to expose a section of optical fiber bundle 10 respectively.

[0030] Step 2: Install the cable clamps 2 on both ends of the submarine optical cable, and then clamp the optical cable clamps 3 on the cable fixing pile head 3 and the force value loading pile head 6 respectively. The above optical cable clamps 3 are fixed according to the submarine optical cable and The structure of the pile head is specially made.

[0031] Step 3: Fix the optical fiber bundles at both ends of the submarine optical cable by dispensing glue, one end of which is fixed on the optical fiber tension sensor 5 through the glue dispensing fixing groove 4, the above optical fiber tension sensor 5 is arranged inside the cable fixing pile head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com