Ultra-high sensitivity medium-wave cooling infrared athermal lens and its working method

A sensitivity and lens technology, applied in instruments, installations, optics, etc., can solve the problems of low sensitivity, slow response, indistinguishable objects with subtle differences, etc., and achieve the effect of high resolution, light lens, and low distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

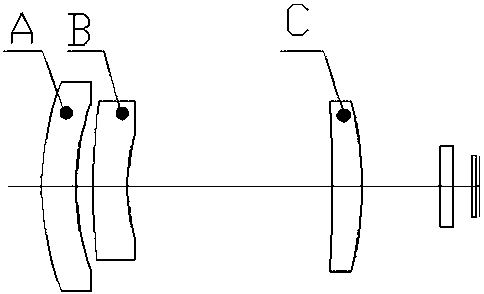

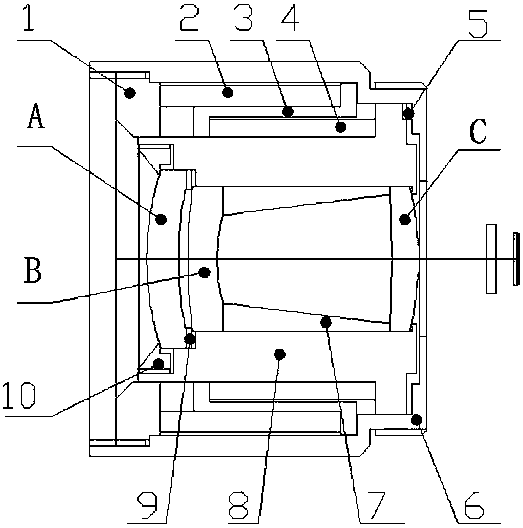

[0024] Such as Figure 1~2 As shown, the ultra-high-sensitivity medium-wave cooling infrared athermalization lens of the present invention has a negative crescent lens A, a negative crescent lens B, and a positive crescent lens C in the optical structure along the incident direction of light.

[0025] In this embodiment, the air gap between the negative crescent lens A and the negative crescent lens B is 1.5 mm, and the air gap between the negative crescent lens B and the positive crescent lens C is 16 mm.

[0026] In this embodiment, the mechanical structure of the lens mainly includes the main lens barrel 8, the outer cover 6, the limit pressure ring 1, the front pressure ring 10, the elastic gasket 5 and the first telescopic lens for mechanical athermalization adjustment function. Ring 2, fixing piece 3, second telescopic ring 4, the lens i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com