Measurement and control method in suspension pouring construction process of continuous rigid frame bridge

A measurement and control method and technology for rigid-frame bridges, applied in special data processing applications, instruments, electrical digital data processing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

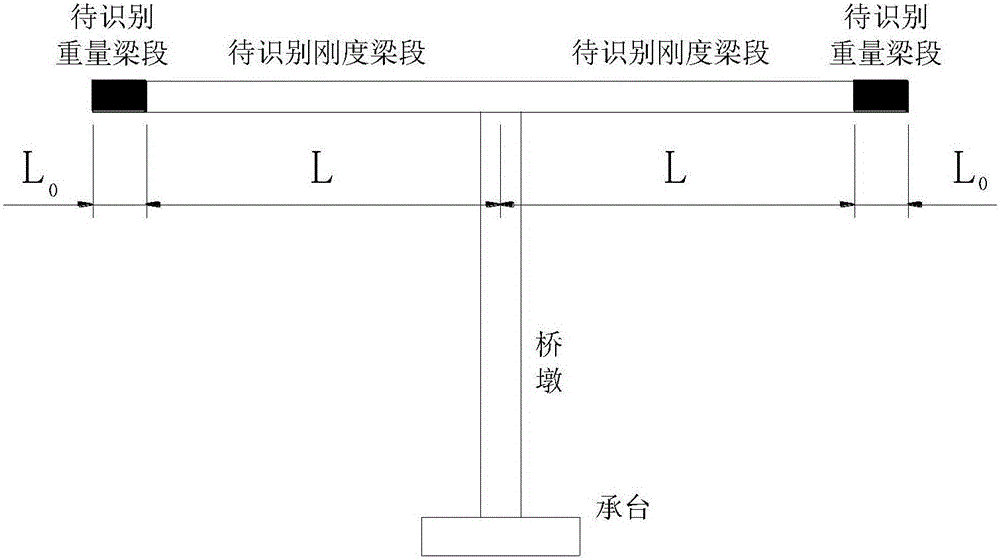

[0035] The steps of the inventive method are as follows:

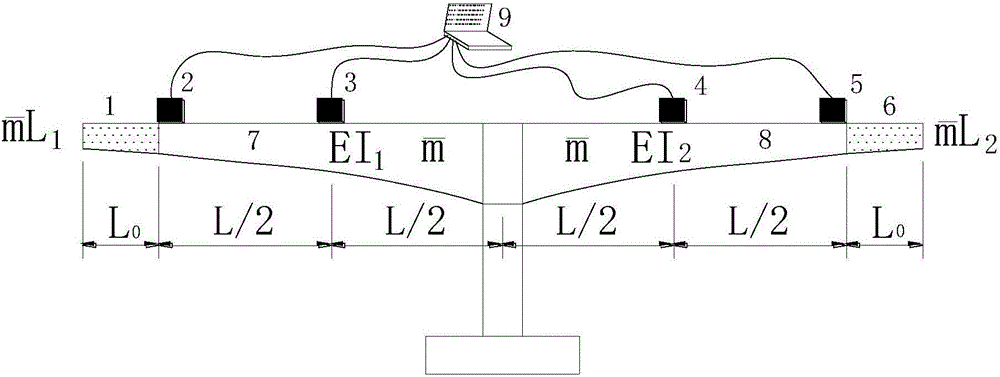

[0036] attached image 3 Among them, 1 and 6 are weight beam sections to be identified, 2, 3, 4, and 5 are four measuring points, 9 is a data testing and analysis system, and 7 and 8 are stiffness beam sections to be identified.

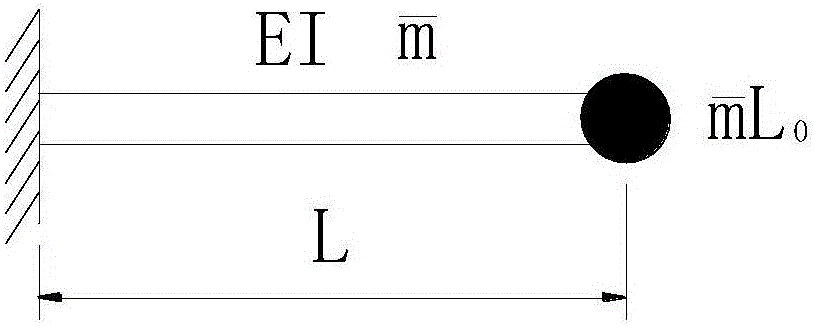

[0037] (I) Test the frequency spectrum data of the four measurement points 2, 3, 4, and 5 before the pouring of the weight beam sections 1 and 6 to be identified, and obtain the first-order frequency and mode shape eigenvalues. Through these six parameters, the least square method is used to obtain the comprehensive stiffness EI of stiffness 7 and 8 to be identified 1 and EI 2 (Note: The mass per unit length has been accurately identified in the previous cantilever construction).

[0038] (II) Test the frequency spectrum data of the four measurement points 2, 3, 4, and 5 after the pouring of the weight beam sections 1 and 6 to be identified, and obtain the first-order frequency and mode sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com