Optical axis parallelism calibrating system and calibrating method

The technology of a calibration system and calibration method, which is applied in the optical axis parallel calibration system and calibration field, can solve the problems of the optical axis parallelism of the optical system, and achieve the effects of good real-time performance, simple testing equipment, and less process variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

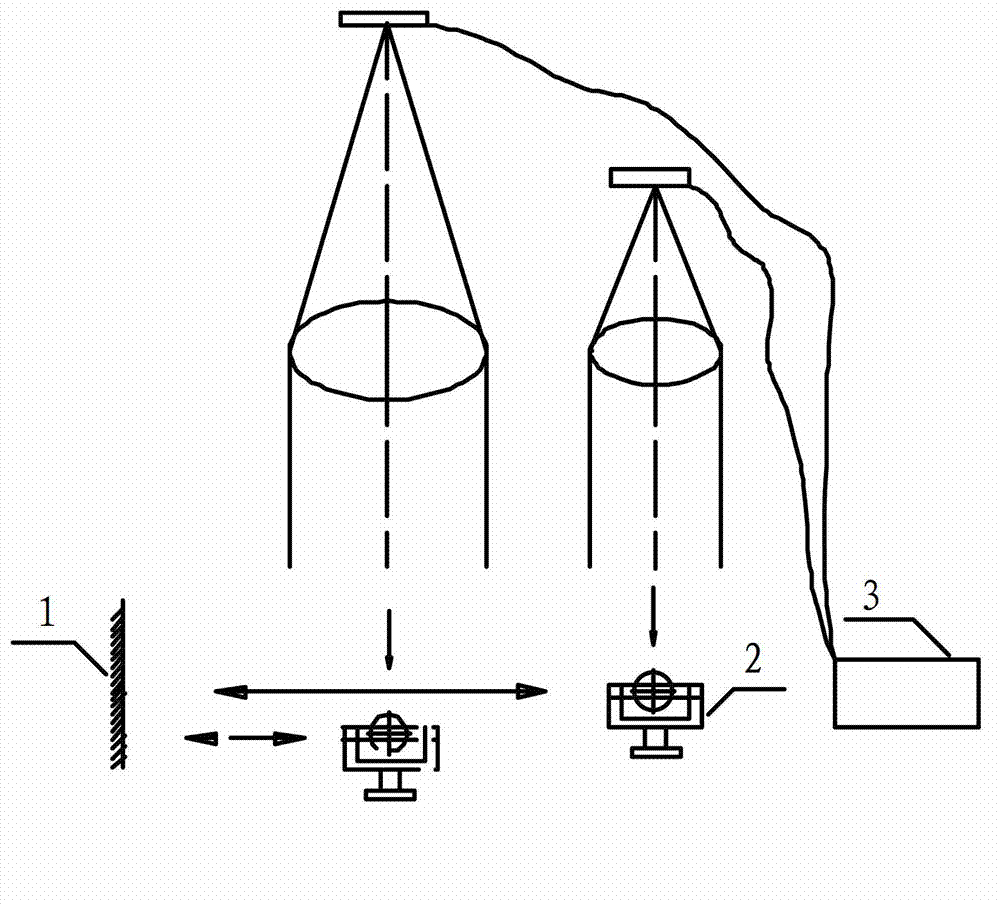

[0023] see figure 1 , the present invention provides a kind of optical axis parallelism calibration system, this optical axis parallelism calibration system comprises autocollimation theodolite 2, data processing computer 3 and is used for self-collimation plane mirror 1 to autocollimation theodolite 2; The optical system to be tested is arranged on the outgoing optical path of the autocollimation theodolite 2 and is electrically connected to the data processing computer 3; the optical system to be tested is a multi-optical axis system, preferably a multi-optical axis system with multiple sensors.

[0024] While providing the above-mentioned calibration system, the present invention also provides a calibration method based on the calibration system, the method comprising the following steps:

[0025] 1) Place the autocollimation theodolite 2 in front of the first sensor of the multi-optical axis system, turn on the laser of the photoelectric autocollimation theodolite 2, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com