Laser beam quality control method for ultra-multi-pass amplification system

A technology of laser beam quality and amplifying system, applied in the field of laser beam quality control of super multi-pass amplifying system, can solve the problems of serious aberration accumulation effect of amplifying pulses, and the beam quality is not significantly improved, so as to avoid the problem of aberration accumulation, Effective light transmission, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for controlling the quality of a laser beam in an ultra-multipass amplification system, comprising the following steps:

[0040] S 1 : measuring the internal aberration of the amplifying cavity, and correcting the internal aberration;

[0041] S 2 : measuring the total optical path aberration, and correcting the total optical path aberration.

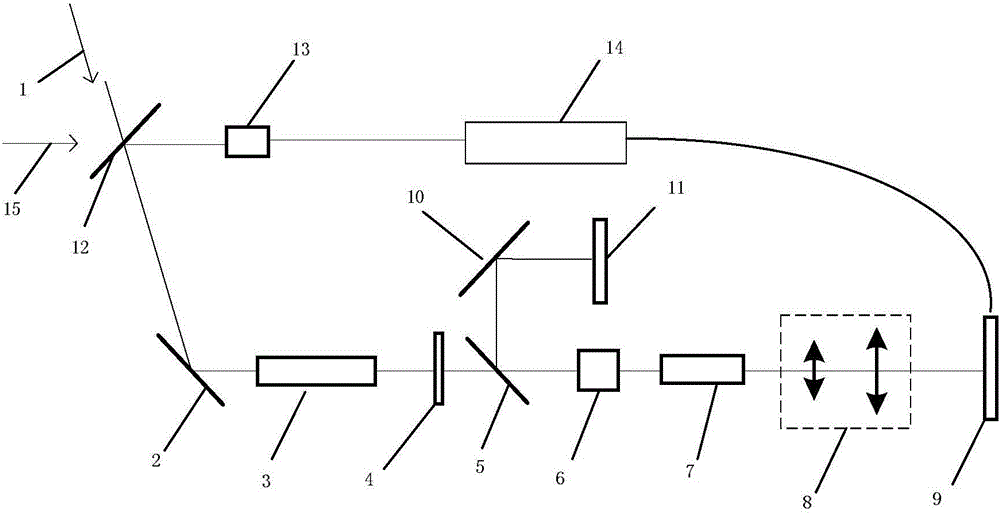

[0042] The super multi-pass amplification system such as figure 1As shown, the beam aperture of laser 1 is 8×8mm, the wavelength is 1053nm, the pulse width is 3ns, p-state polarized light, the parameters of the calibration light 15 are the same as those of laser 1, and the mirror 1 has a high reflectivity for laser 1. The diameter of the standard flat mirror 4 is 20×20mm, and it has high reflectivity to 1053nm laser 1, and the beam splitter 15 has high transmittance to p-state polarized light, and high reflectivity to s-state polarized light, and the size of laser amplifying medium 7 is 12× 12×30mm, the beam expansio...

Embodiment 2

[0059] The same part of this embodiment and Embodiment 1 will not be repeated, the difference is:

[0060] The beam diameter of laser 1 is 10×10mm, the wavelength is 1053nm, the pulse width is 1ns, p-state polarized light, the size of laser amplification medium 7 is 15×15×40mm, and the beam expansion ratio of spatial filter system 8 is 1:6. The diameter of the cavity mirror 11 is 20×20 mm, and the wavefront corrector 9 is a piezoelectric film-driven deformable mirror, and its parameters are shown in Table 3:

[0061]

[0062] , the wavefront detector 13 is a Hartmann wavefront sensor, and its parameters are as shown in Table 4:

[0063]

[0064]

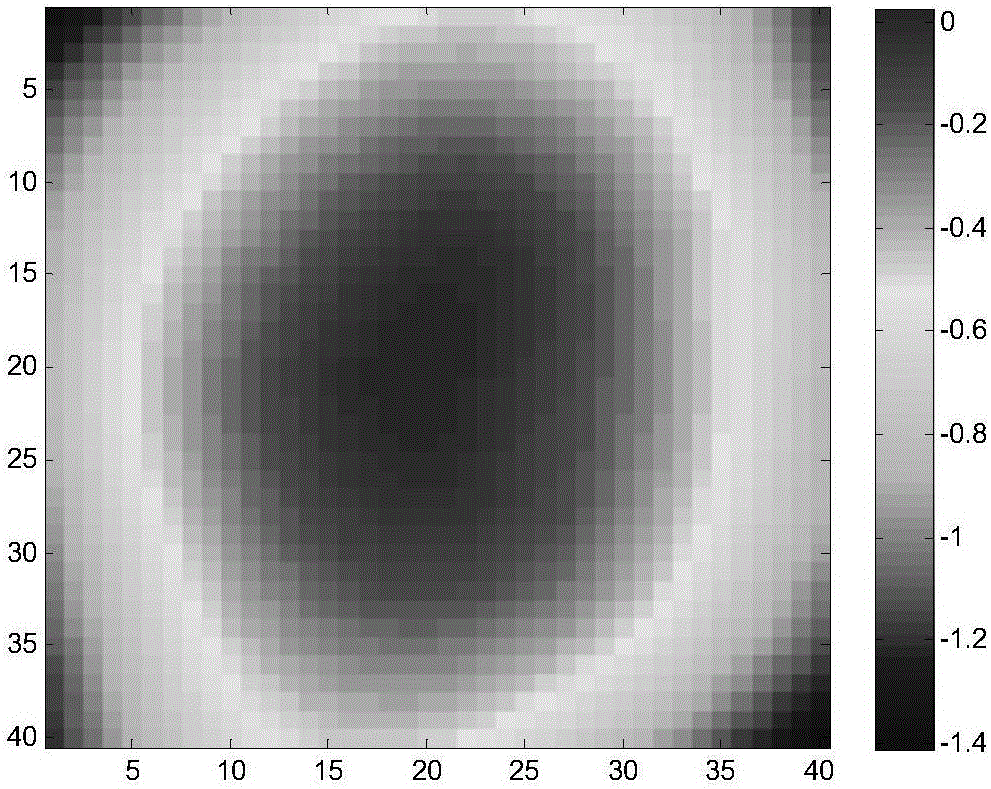

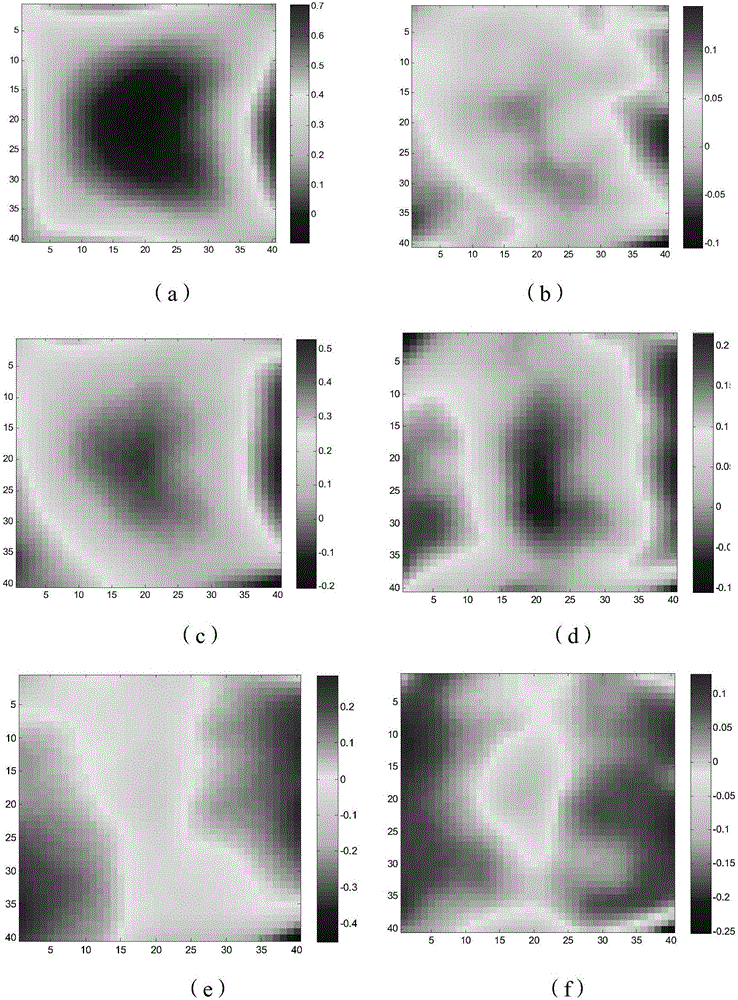

[0065] In this embodiment, the amplification system is an eight-pass amplification, and the optical path aberration W outside the amplification cavity is measured 1 , and its corresponding wavefront distribution is shown in Figure 4 As shown, the wavefront distortion is 0.42 wavelength; when the laser optical path is doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com