Straight vertical pin clamp

A pin pliers, straight line technology, applied in the field of pin cancellation, can solve the problems of pin falling, falling objects, and increasing the risk of operation, and achieve the effect of convenient operation, reducing risks, and reducing the risk of falling objects from high altitudes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

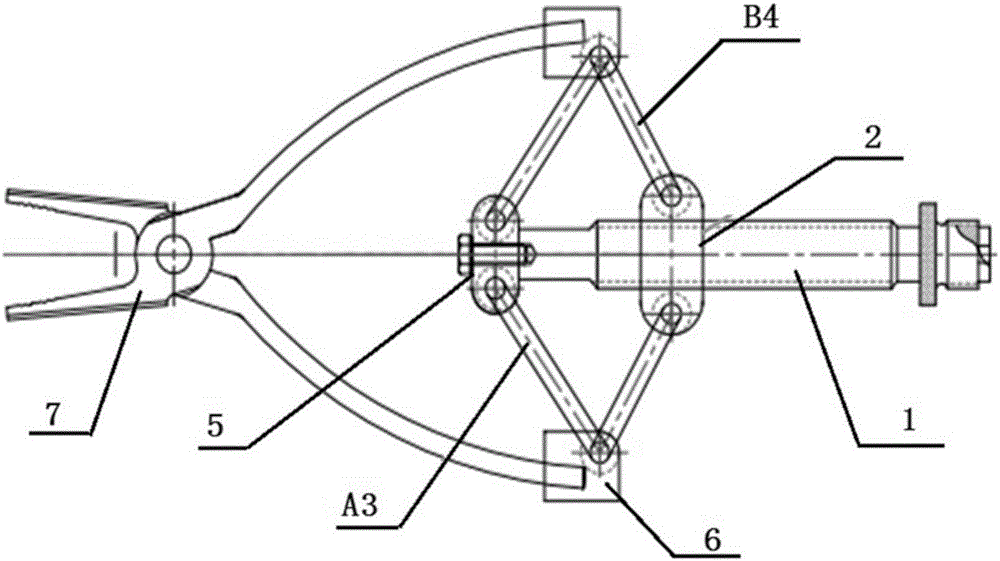

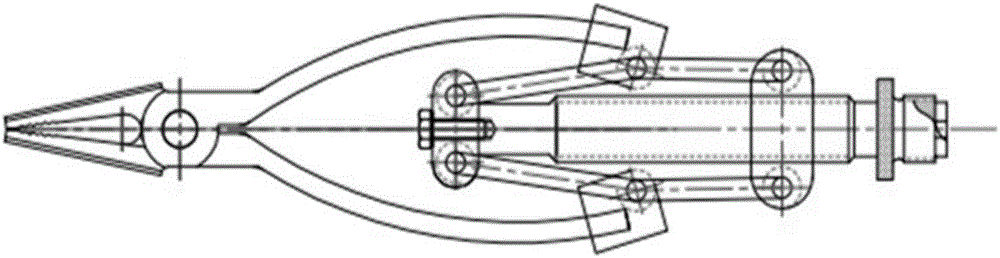

[0013] See figure 1 , a straight line vertical pin removal pliers, the present invention is characterized in that it includes a pin removal pliers 7 and an operating rod 1 connected with the pin removal pliers 7, wherein the shaft working section of the operating rod 1 is provided with threads, and on the working section A rotary connector 2 is screwed, and the two radial sides of the rotary connector 2 are symmetrically arranged to be respectively hinged with one end of the second connecting rod A3 and one end of the second connecting rod B4. One end and the other end of the second connecting rod B4 are respectively symmetrically hinged on both sides of the threaded top 5 in the radial direction; handle connectors 6 are fixed at the two tail ends of the handle of the pliers body 1, the middle hinge fulcrum of the second connecting rod A3, the second connecting rod B4 The middle hinge fulcrum of each is hingedly connected with the handle connector 6 respectively.

[0014] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com