A multi-source data power plant inspection management system

A management system and subsystem technology, applied in the field of multi-source data power plant inspection management system, can solve the problems of complicated parameters, time-consuming and labor-intensive, etc., and achieve the effect of reducing the amount of calculation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described in conjunction with the following examples.

[0015] Application Scenario 1:

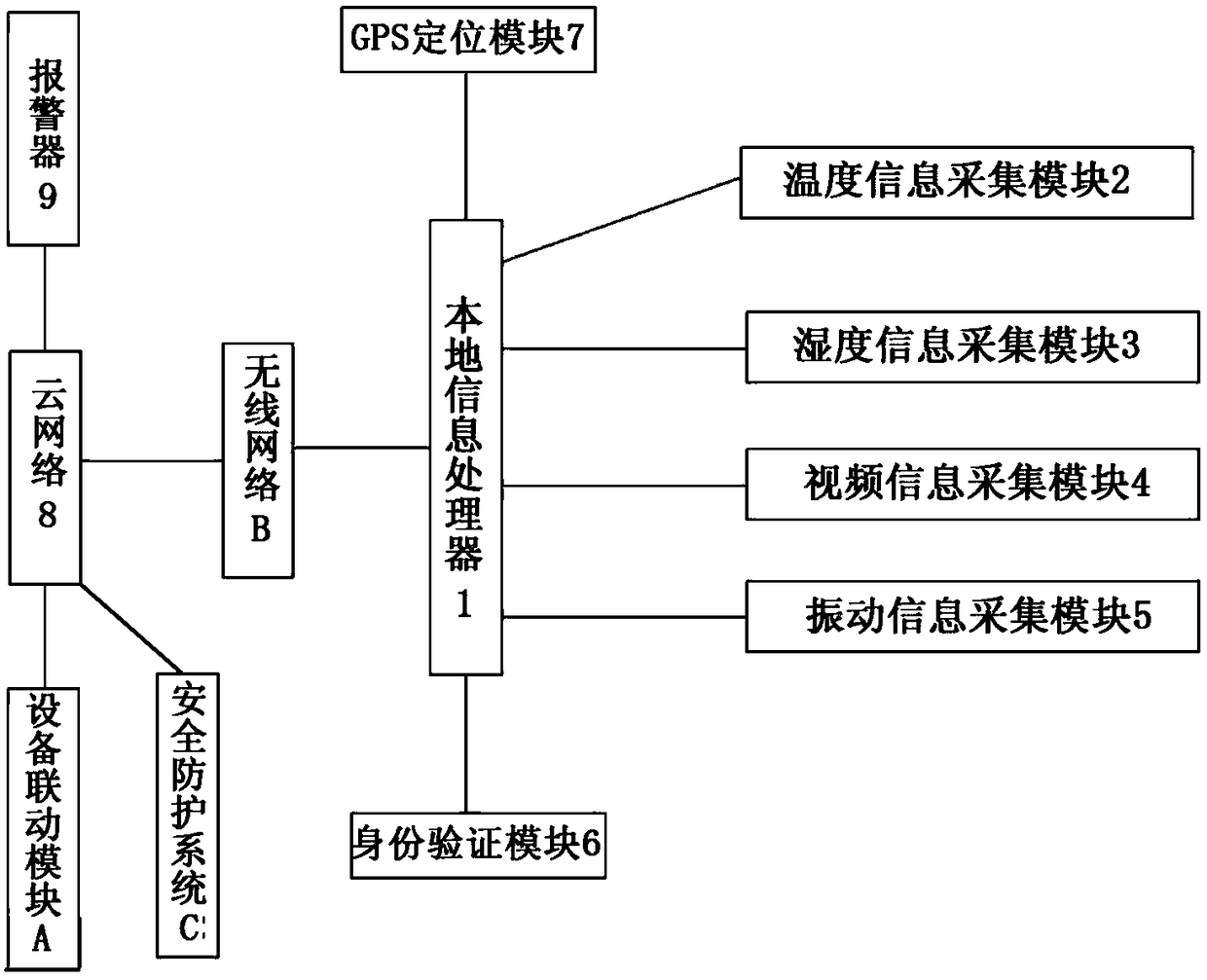

[0016] Such as figure 1 A multi-source data power plant inspection management system shown includes a local information processor 1, a temperature information collection module 2, a humidity information collection module 3, a video information collection module 4, a vibration information collection module 5, an identity verification module 6, GPS positioning module 7, cloud network 8, alarm 9, equipment linkage module A and security protection system C.

[0017] The temperature information collection module 2, the humidity information collection module 3, the video information collection module 4, and the vibration information collection module 5 are all integrated on the patrol instrument carried by the patrol inspector, and are used to collect temperature, humidity, video and vibration respectively. information, and upload the information to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com