hydraulic winch

A hydraulic winch and winch technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problem of increasing the space of the winch, limiting the improvement of the winch's on-board capacity, affecting the life of the wire rope, etc. Convenience, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

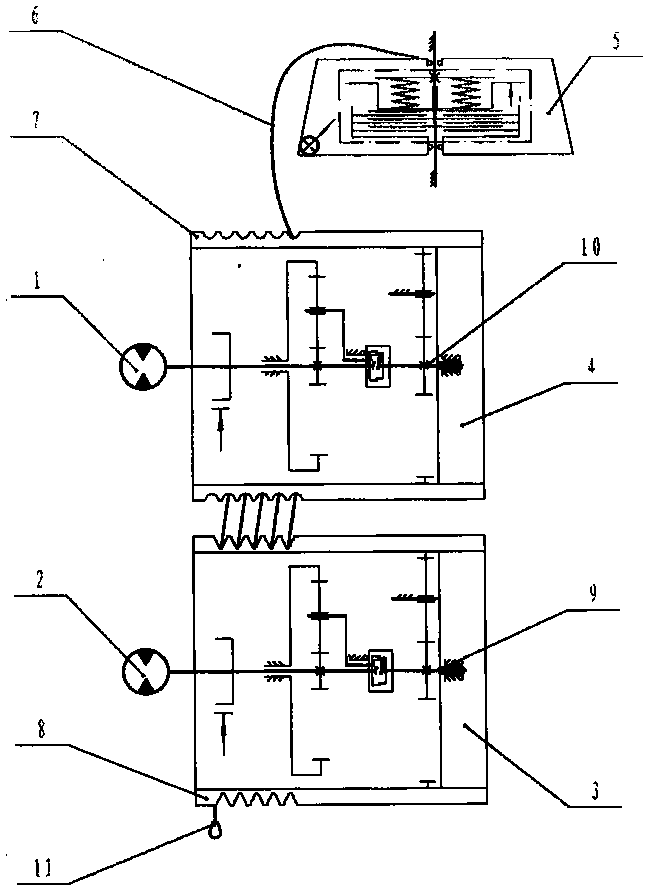

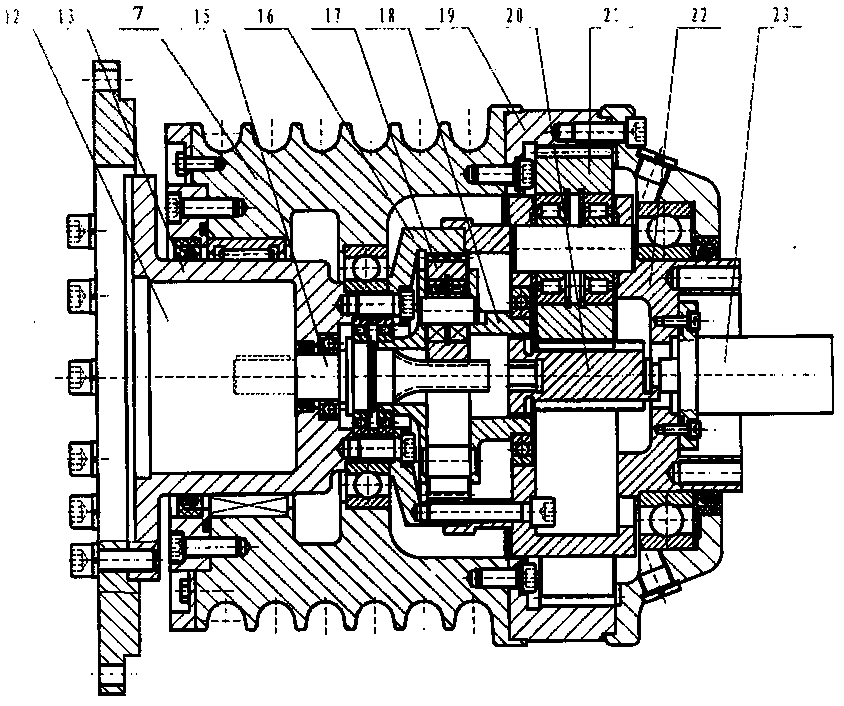

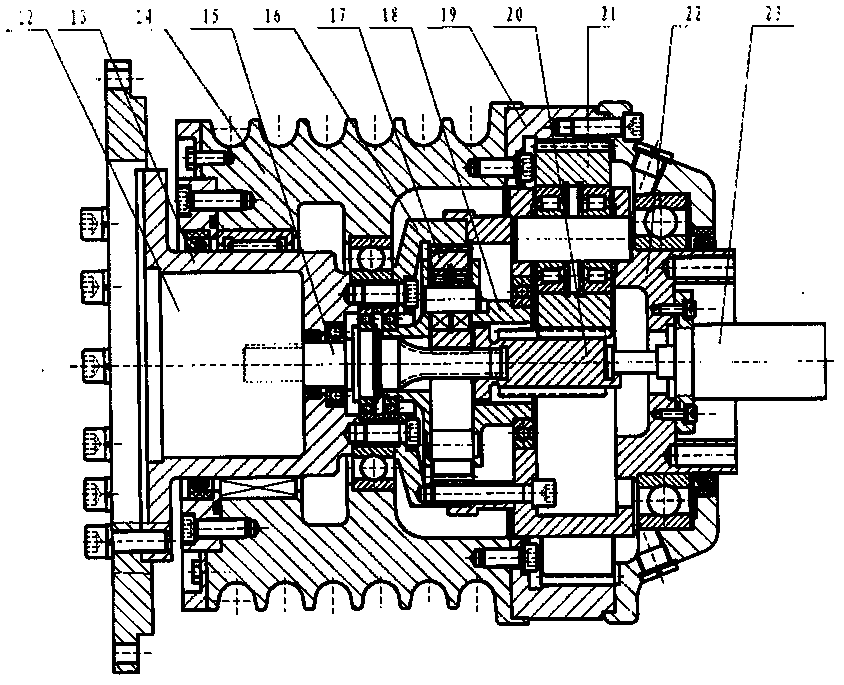

[0017] The mechanical transmission diagram of the hydraulic winch of the present invention is shown in figure 1 , consists of winch power device and rope storage device 5, and the two are connected by guide rail 6. The winch power device is mainly composed of motor 1, motor 2, front friction drum assembly 4, and rear friction drum assembly 3. There are rope grooves on the two friction drum assemblies, and the steel wire rope 11 forms the same winding direction along the outer side of the second friction drum assembly. Through each rope groove in turn, the two friction roller assemblies are connected together, and the friction force between the roller rope groove and the wire rope is used to transmit the motor 1 and motor 2 to the front friction roller 7 and the rear friction roller 7 through the reducer 9 and the reducer 10. The torque of the friction drum 8 is converted into the pulling force on the wire rope 11 to realize the constant pulling force output of the winch. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com