Tea leaf spreading airing device

A tea and tea storage technology, which is applied in the field of drying equipment, can solve the problems of frequent operation of tea leaves, moving plates and gauze nets, etc., and achieve the effect of convenient and convenient recycling

Inactive Publication Date: 2016-11-23

正安县清新种养殖农民专业合作社

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The present invention intends to provide a tea drying device to solve the current problem that the tea is exposed to wind on one side and requires frequent operation of the moving plate and gauze

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

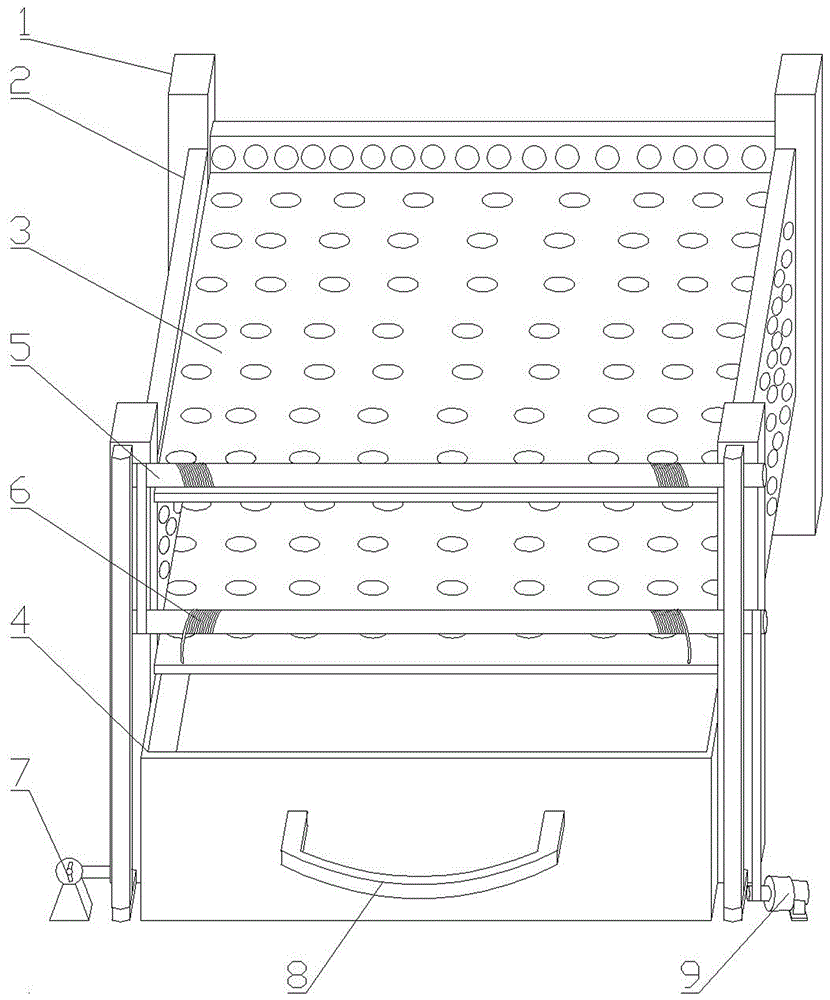

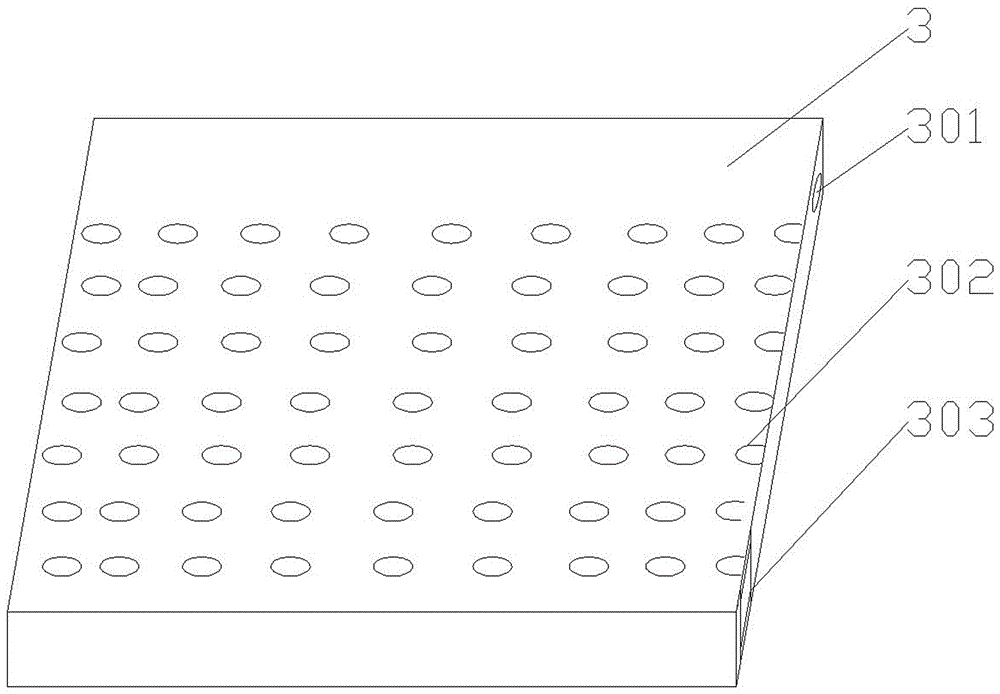

The invention discloses a tea leaf spreading airing device in the field of spreading airing equipment. The tea leaf spreading airing device comprises at least one support plate, each support plate is in a square shape, stand columns are connected to the four corners of the support plates respectively, a baffle is arranged between every two adjacent stand columns, each support plate is of a hollow structure, small holes communicated with the interior of each support plate are evenly distributed on the upper face and the lower face of the support hole, and each stand column is of a hollow structure; an opening is formed in the joint of each stand column and the corresponding support plate, and the internal hollow structure of each stand column is communicated with that of the corresponding support plate; one end of each support plate is hinged to the corresponding baffle, ropes are connected to the other end of each support plate, the other ends of the ropes are connected with power equipment, and a fan is connected to one stand column. Due to the fact that the stand columns and the support plates all adopt the hollow structures, and the small holes communicated with the interior of each support plate are formed in the upper face and the lower face of the support plate, airflow generated by the fan can conduct uniform spreading airing on tea leaves at the upper side and the lower side through the hollow structures, the power equipment is adopted for driving the ropes, and the tea leaves can be rapidly recycled at a time; the problem that in the prior art, the tea leaves are subjected to a wind at one side is solved, and the work efficiency is improved.

Description

technical field [0001] The invention relates to the field of drying equipment, in particular to a tea drying device. Background technique [0002] Tea drying is a tea processing process that spreads the picked fresh tea leaves according to a certain thickness, and through drying, redistributes the water in each part of the fresh leaves evenly, distributes the heat between the leaves, and reduces the rate of water loss and chemical change; It plays an important role in ensuring the quality of tea processing, and is also a necessary condition for subsequent processing procedures. [0003] At present, tea leaves are generally placed in air-drying devices on the market, but some of the air-drying equipment currently used do not use fans, and the water loss is slow, and the withering process is long, making the airing cycle long; some design There is a fan, but the board where the fan is installed is not solid, but is composed of slats at equal intervals. There are gaps between ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23F3/06

CPCA23F3/06

Inventor 宋涛宋尔军

Owner 正安县清新种养殖农民专业合作社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com