Full-automatic shoe cleaning machine

A shoe washing machine, fully automatic technology, applied to the cleaning of boots and shoes, cleaning equipment, household appliances, etc., can solve the problems of lack of cleaning, disinfection, drying, incomplete physical cleaning of the shoe washing machine, and no shoe washing machine. , to achieve the effects of saving procurement costs, high degree of automation, and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] basic structure

[0039] Definition of terms in this article: One side or one end of the door of the shoe washing machine is called "front", and the opposite side or one end is called "back" or "bottom".

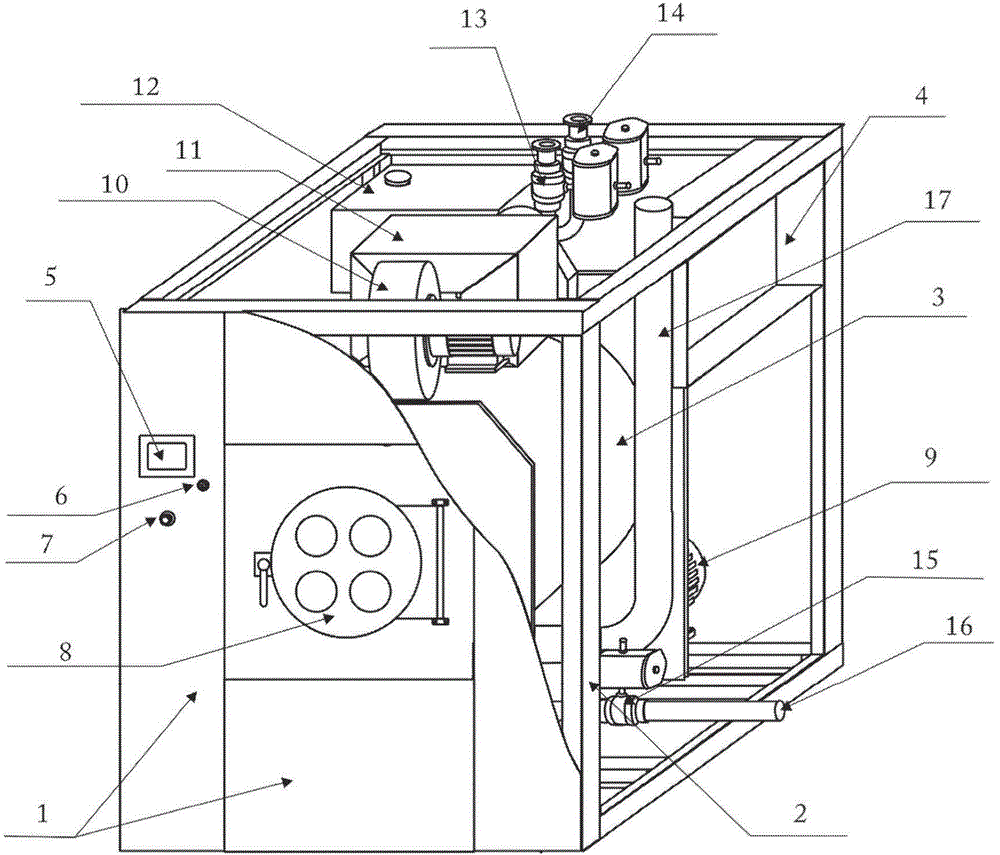

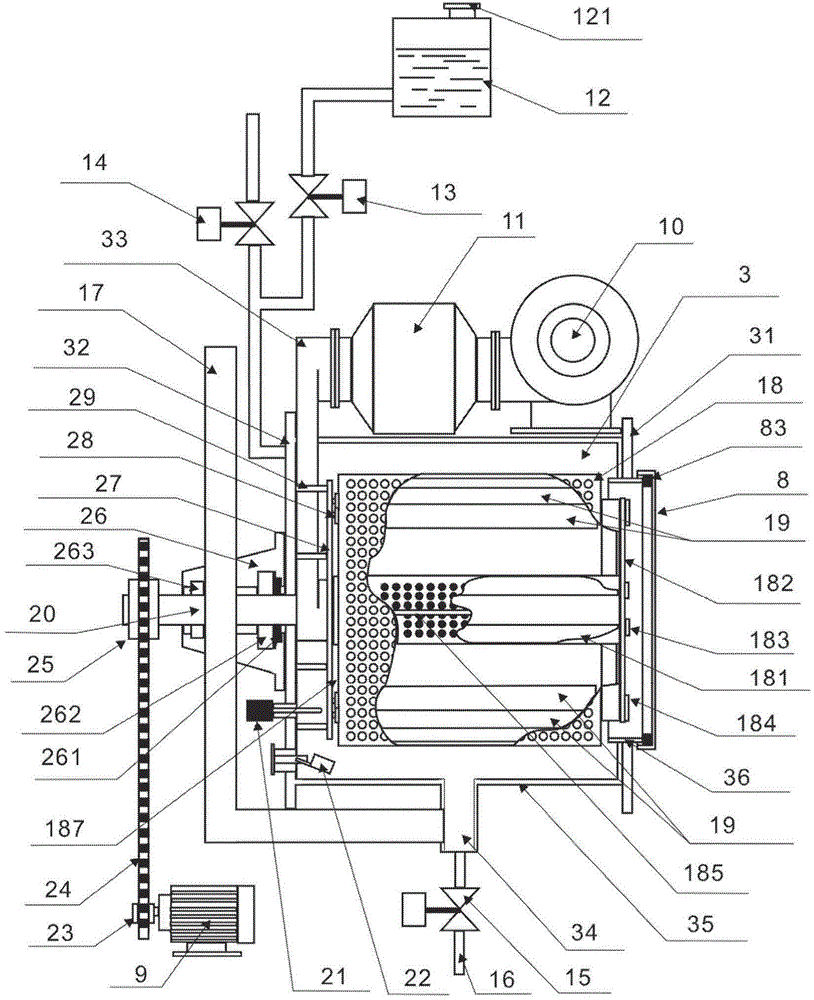

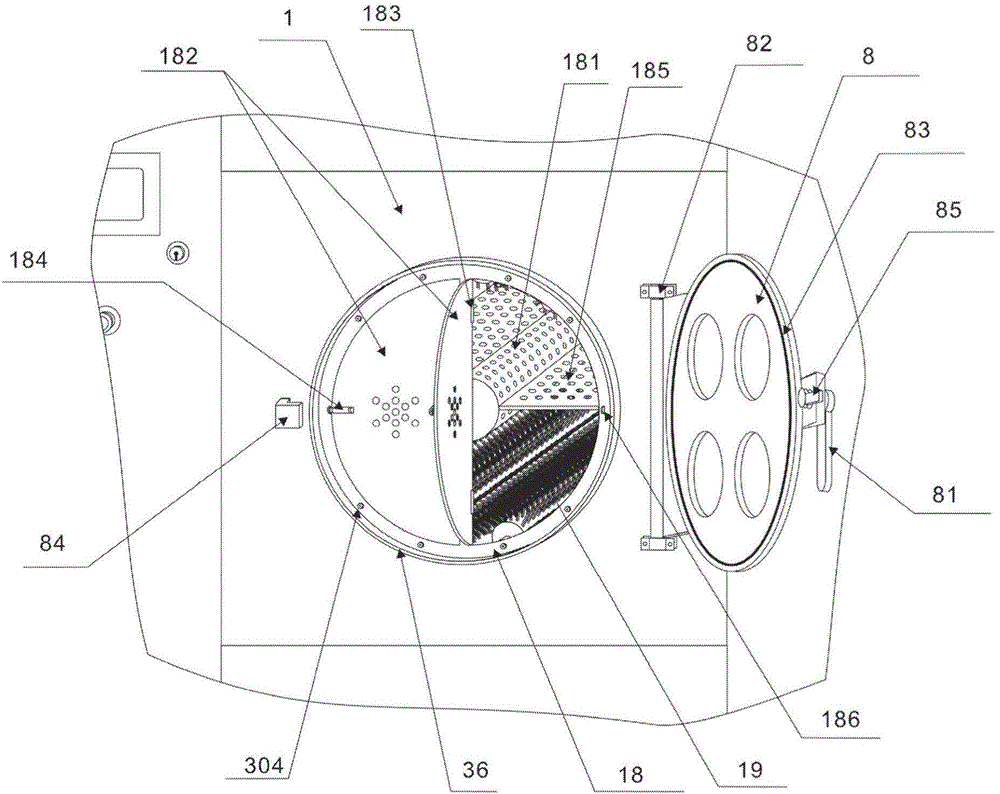

[0040] figure 1 , figure 2 , image 3 and Figure 4 A specific embodiment according to the principle of the present invention is shown, the shoe washing machine of this embodiment comprises a cylindrical container 3 and a frame 2, the cylindrical container 3 is fixed on the frame 2, and the cylindrical container 3 includes a Some large and small holes of cylinder body 35, container front plate 31, container rear plate 32, air inlet duct 33, container discharge port 34, and container door frame 36 arranged in container front plate 31. The cylinder body 35 , the container front panel 31 and the container rear panel 32 define the cavity of the cylindrical container 3 . Some large and small holes of the barrel body 35 are used to install various pipelines leading in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com