Regeneration method of soft water resin

A water softening resin and softening resin technology, applied in the direction of ion exchange regeneration, chemical instruments and methods, ion exchange, etc., can solve the problem of easy breeding of bacteria in the salt box, and achieve the effect of saving the amount of salt and avoiding the breeding of bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

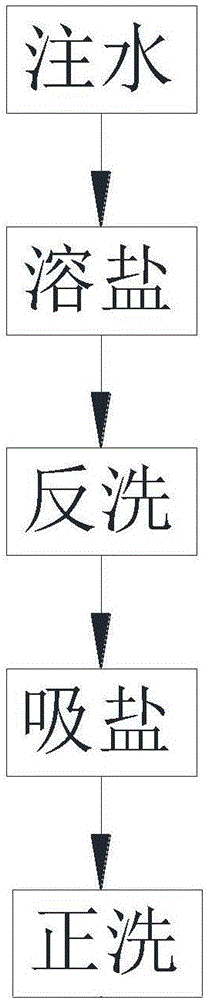

[0020] Such as figure 1 Shown, the regeneration method of a kind of soft water resin of the present invention may further comprise the steps:

[0021] 1) Water injection: inject water into the salt tank containing regeneration salt;

[0022] 2) Dissolved salt: wait for the regenerated salt to melt to obtain brine for regeneration;

[0023] 3) Backwashing: inject water into the water inlet at the bottom of the resin tank containing the soft water resin, and the water flow reversely washes the softened resin from bottom to top, and disperses the softened resin;

[0024] 3) Salt absorption: inject brine for regeneration into the resin tank to react with the softened resin to regenerate the softened resin;

[0025] 4) Positive washing: inject water into the water inlet on the top of the resin tank, and the water flows from top to bottom to reversely wash and soften the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com