Mobile high-speed steel die rapid dust exhaust apparatus

A dust collection device, high-speed steel technology, applied in the direction of cleaning methods and appliances, cleaning methods using gas flow, chemical instruments and methods, etc., can solve the problems that the dust removal device cannot clean the dust of steelmaking molds, and it is inconvenient to move, so as to achieve improvement Dust removal efficiency, the effect of avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

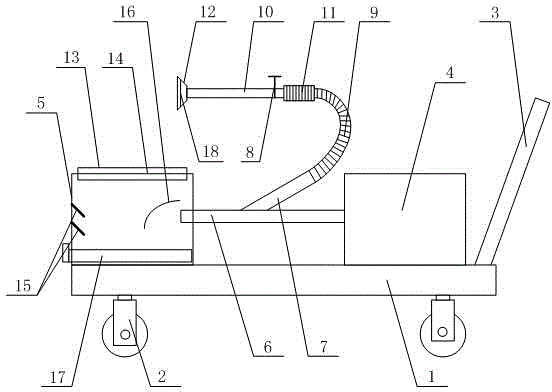

[0009] Such as figure 1 As shown, the mobile high-speed steel mold fast dust suction device of the present invention includes: a base plate 1, a universal wheel 2 installed below the base plate 1, a handrail 3 installed on the rear edge of the base plate 1, an air compressor 4, and a collection box 5 , blowing pipe 6, suction pipe 7, flexible pipe 9, air inlet pipe 10 and handle 11. Wherein, the air compressor 4 and the collecting box 5 are all installed on the base plate 1; the blowing pipe 6 is connected between the air compressor 4 and the collecting box 5; , and the suction pipe 7 is inclined to the air compressor 4; one end of the hose 9 is butted and installed on the other end of the suction pipe 7, and the other end is butted and installed on one end of the air inlet pipe 10; the handle 11 is sleeved on the air inlet On the pipe 10, a valve 8 is provided on the air inlet pipe 10; an air outlet window 13 is provided on the top of the collection box 5, and a filter scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com