Method for detection of ink residual, ink residual detection mechanism, ink supply system and ink jet printer

A technology for detecting mechanism and ink volume, which is applied in the field of detecting ink remaining and inkjet printers. It can solve the problems of inaccurate detection of ink remaining and achieve the effect of improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for detecting the remaining amount of ink, which is used for detecting the presence or absence of ink, comprises the following steps:

[0044] 1. Set a predetermined value greater than the normal suction power;

[0045] 2. Detecting the amount of ink The detection part detects whether there is ink in the position, if there is, it will print normally, if there is no ink, then enter step 3;

[0046] 3. Compare the real-time suction power with the predetermined value, if the real-time suction power is less than the predetermined value, go to step 4, otherwise, go to step 5;

[0047] 4. Increase the suction power and go to step 2;

[0048] 5. Reminder that the ink is exhausted.

[0049] In step 2, it may further comprise that the ink quantity detecting component transmits the first electrical signal indicating that there is no ink at the position to the controller.

[0050] In step 2, it may also include that the ink quantity detection component transmits the fi...

Embodiment 2

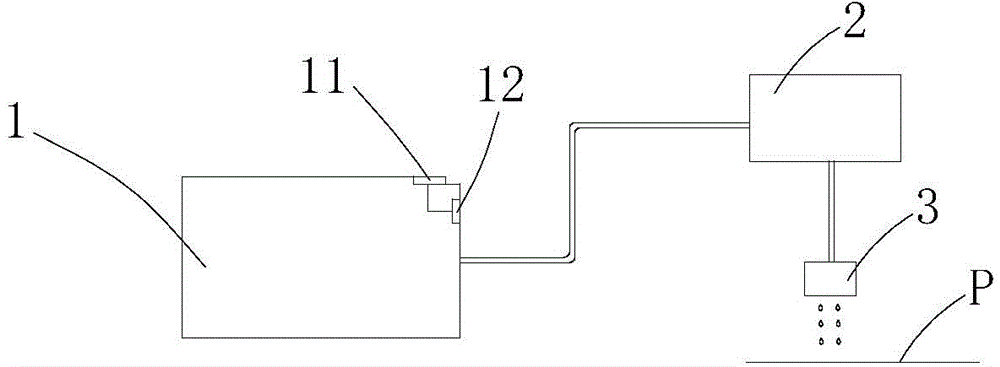

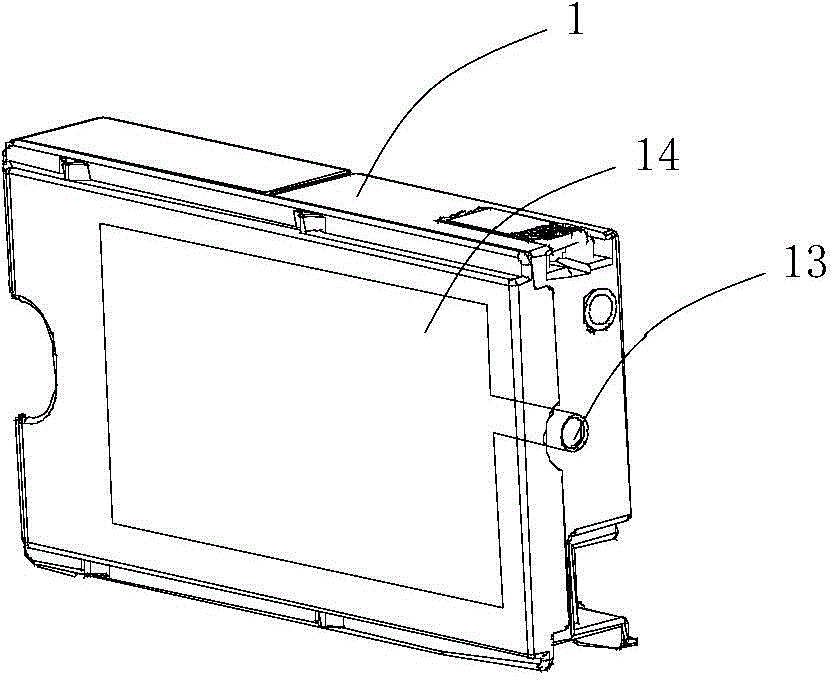

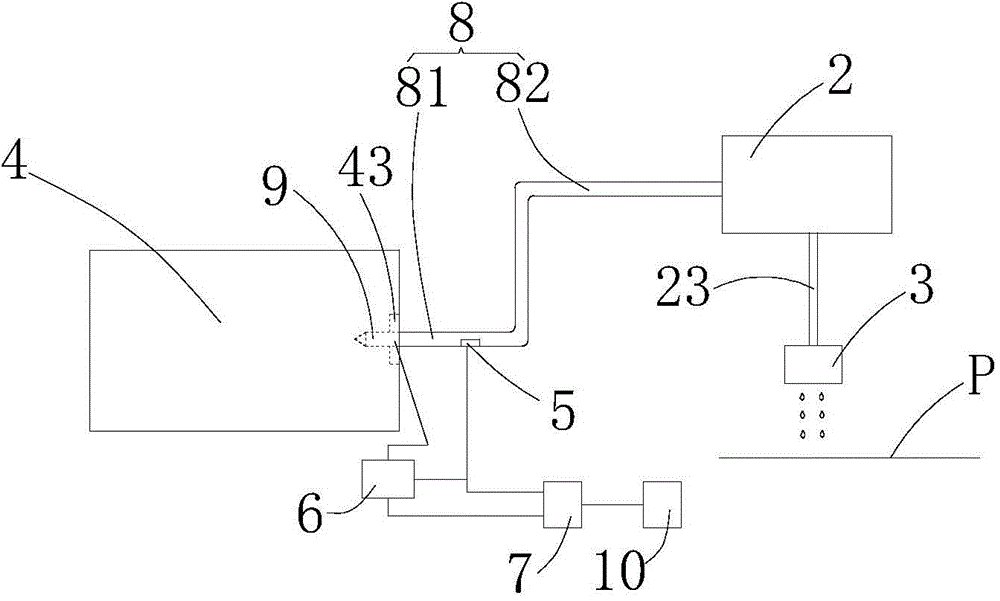

[0055] image 3 Embodiment 2 is a schematic diagram of an ink supply system in a printer utilizing the method of Embodiment 1. Inkjet printers, including: ink supply systems, printing equipment. The ink supply system in an inkjet printer is like image 3 The ink supply system shown includes: an ink remaining detection mechanism, a secondary ink chamber 2 , an ink channel 23 , a print head 3 , and a terminal device 10 . Ink is sprayed from the ink supply system onto the medium P (generally paper) according to the printing task. The remaining ink amount detection mechanism is used to detect whether the ink amount is in an ink-end state. The remaining ink amount detection mechanism includes: an ink cartridge 4 , an ink suction needle 9 , an ink flow path 8 , an ink amount detection component 5 , a suction power control unit 6 , and a controller 7 . The suction power control part is provided with a predetermined value larger than the normal suction power; during the printing p...

Embodiment 3

[0059] Figure 5 It is a schematic diagram of the ink supply system in the printer of the third embodiment. like Figure 5 As shown, the ink cartridge is provided with a chip 41 . Ink quantity information is stored in the chip 41 . like Figure 6 As shown, when the first electrical signal is generated, step S401 will be executed to transmit the first electrical signal to the chip 41 , and after the chip 41 receives the first electrical signal, step S402 will be executed to correct the ink volume information in the chip 41 .

[0060] The first electrical signal generated by the ink volume detection component 5 can correct the ink volume information stored in the chip 41 and improve the accuracy of the stored information in the chip 41 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com