Braking system of large-tonnage storage battery forktruck

A brake system and battery technology, applied in brake safety systems, brakes, cooling brakes, etc., can solve problems such as easy heat generation, attenuation of braking capacity, and easy generation of abnormal noise, so as to prolong service life, reduce pressure loss, Effects without human intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

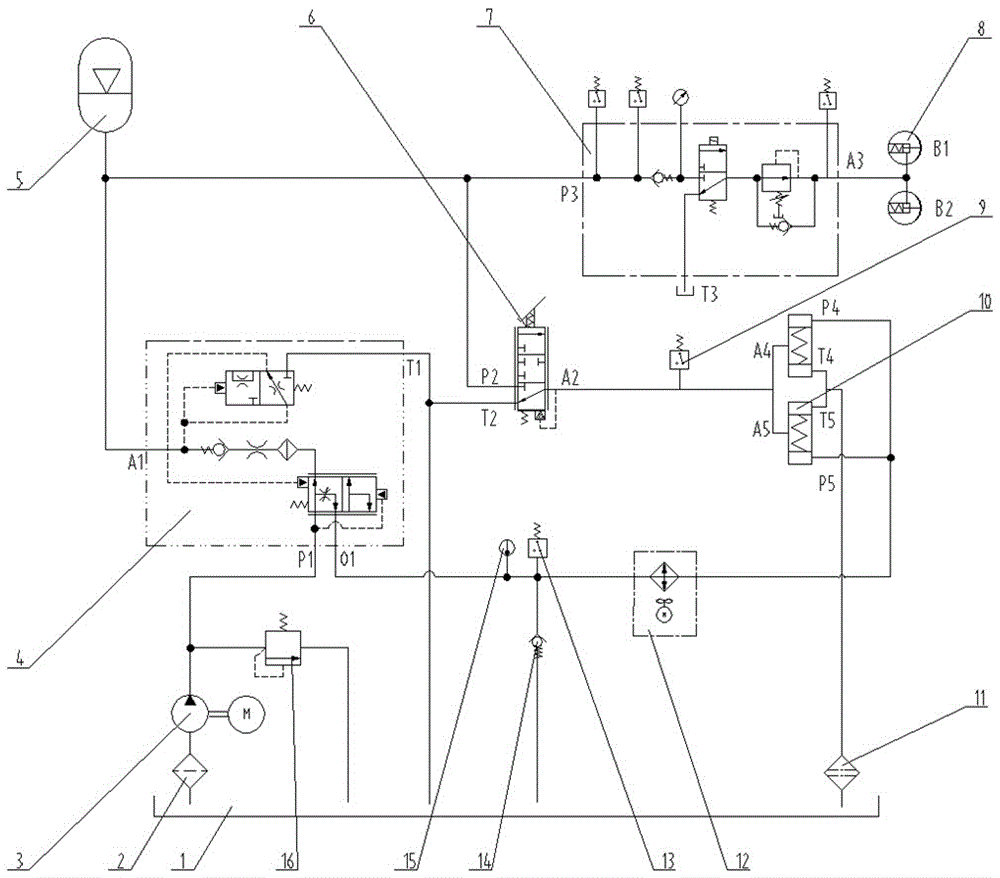

[0037] see figure 1 , the braking system of a large-tonnage battery forklift includes a service brake 10, a parking brake 8 and a hydraulic brake system; the service brake 10 is a wet brake, the parking brake 8 is a disc brake, and the hydraulic brake system includes a brake hydraulic oil tank 1 , Oil pump 3, accumulator 5, filling valve mechanism 4, power brake valve 6 and parking brake valve block 7.

[0038] The oil pump 3 is a gear pump, the inlet of the oil pump 3 is connected with the oil suction filter 2 in series, and the oil outlet of the oil pump 3 is connected with the overflow valve 16 in series.

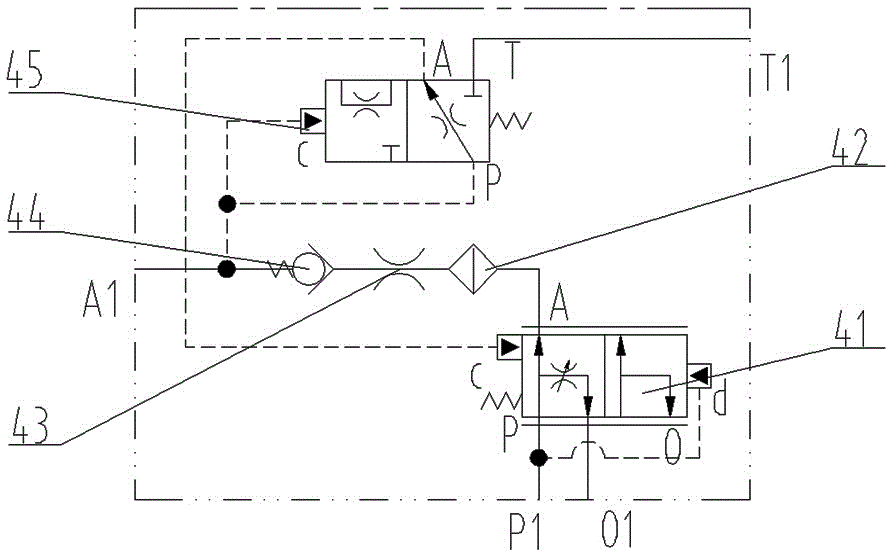

[0039] see figure 2 , The filling valve mechanism 4 includes a pressure compensation valve 41 and a pilot valve 45; both the pressure compensation valve 41 and the pilot valve 45 are two-position two-way valves. The oil outlet A of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com