Peelable thin-film type deicing method for airplanes

A film-type and thin-film technology, which is applied in the field of aircraft peelable film-type deicing, can solve the problems of infeasibility and difficulty in deicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

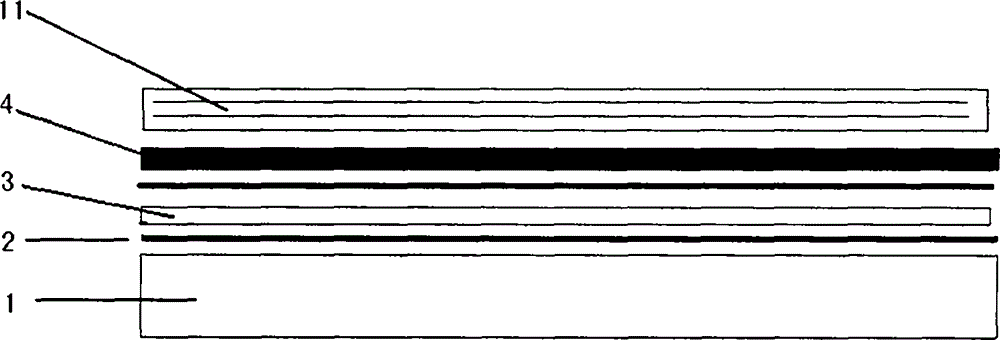

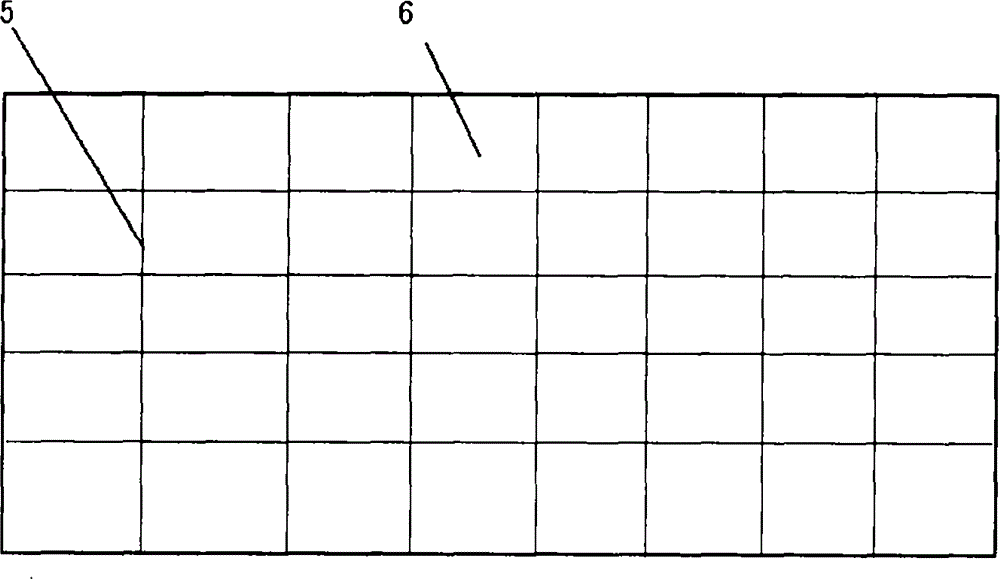

[0022] On the surface of the aircraft shell 1, a large piece or even a whole film 4 is spliced with a plurality of film segments 6, and each film segment 6 is independent, and a segmented splicing line 5 is formed between adjacent blocks; corresponding to the segmented splicing line 5 At the place, there is a thermal cutting line 8 composed of resistance wire; between the film 4 and the aircraft shell 1, and between the film 4 and the film 4, there is a heating layer 3; when the aircraft shell 1 freezes, turn on the heating Layer 3 heats the power supply 9, and connects the thermal cutting line 8 that is made up of resistance wire, like this, the thermal cutting line 8 melts the ice layer 11 from the block splicing line 5 or the dividing line 7, and makes the ice layer 11 form and film The melting line matched by the block stitching line 5 of the block 6, that is, the ice layer is cut into a small piece of flake ice layer by the thermal cutting line 8. At this time, due to th...

Embodiment 2

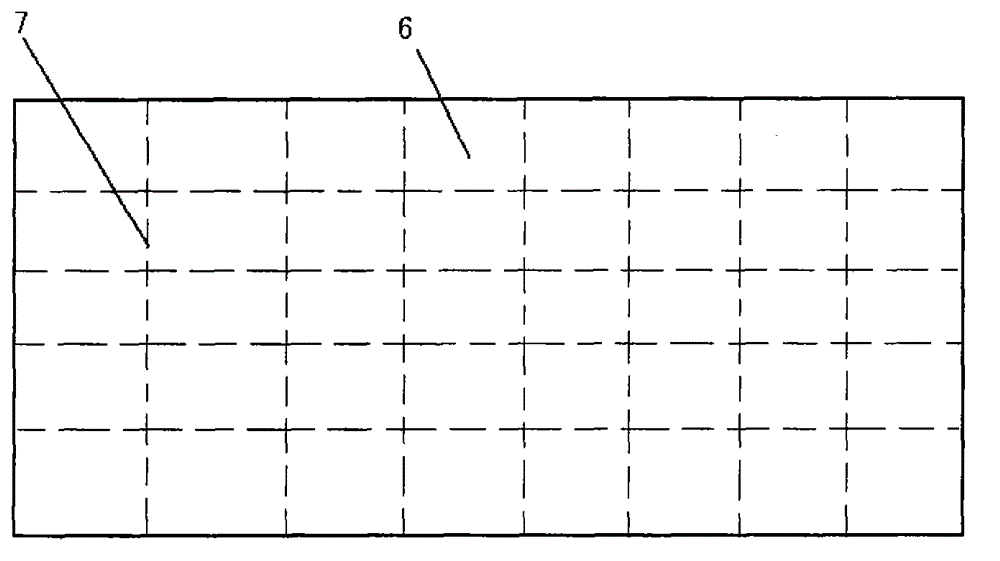

[0024] Embodiment 2 is roughly the same as Embodiment 1, and the difference is that what Embodiment 2 used was a large film with dividing line 7. After freezing on the aircraft shell 1, the heating power supply 9 and thermal cutting of the heating layer 3 were switched on. Line 8 power supply, film 4 is torn and peeled off from parting line 7, and is also torn and peeled off from parting line 7 with a piece of ice layer 11.

[0025] The film 4 is any stickable film. The dividing line 7 is physically divided or chemically divided.

Embodiment 3

[0027] Figure 5 Middle, 5. Block splicing line, 6. Film block, 12. Folding protrusion. The folding protrusion 12 is exactly to fold the edge at the edge of the film segment 6 to form a folding protrusion 12 at a certain angle with the film segment 6 plane. The function of the folding protrusion 12 is that after the film segment 6 freezes, The folded projections 12 tightly covered by the ice layer 11 can be torn off from the splicing line 5 by the falling ice layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com