A hydraulically telescopic conveying arm

A technology of hydraulically telescopic and conveying arms, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., and can solve problems such as unstable shaking of the hull, potential safety hazards, and failure of the four-bar mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

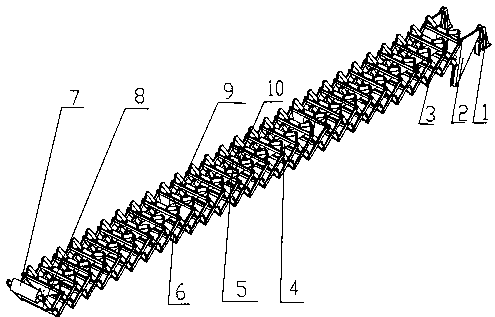

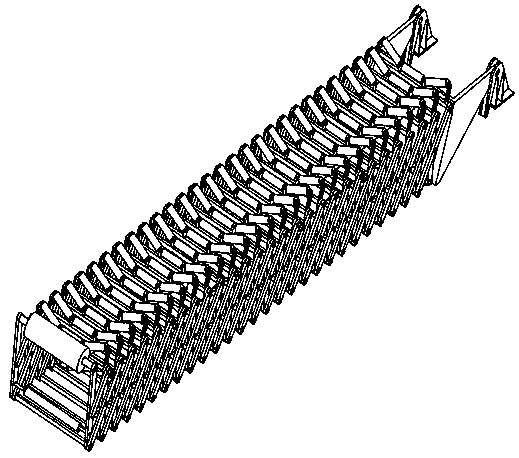

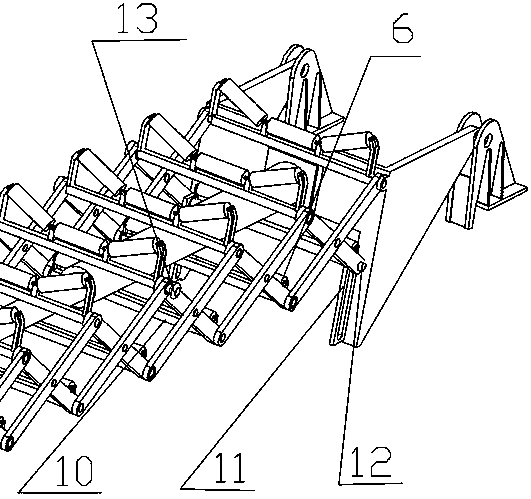

[0021] attached figure 1 Among them, a hydraulically telescopic conveying arm specifically includes a conveying arm base 1, a conveying arm connecting plate 2, a scissors fork conveying arm frame 3, a hydraulic cylinder 4, an upper carrying idler 5, a lower return idler 6, an upper reversing The drum 7, the lower reversing drum 8, the upper boom cross bar 9, and the lower boom cross bar 10.

[0022]In a specific embodiment, the scissors fork delivery arm frame 3 is a left-right symmetrical structure hinged by a plurality of rectangular steel bars. Extend the length of the delivery arm; the scissors fork delivery arm frame 3 is installed on the delivery arm connecting plate 2, and the connection mode between it and the delivery arm connecting plate 2 is hinged; the upper and lower hinges of each scissor fork are provided with The boo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com