Compound type pile foundation construction site structure and compound type pile foundation construction process

A construction site, composite technology, applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of difficult removal of waste residue, pile foundation quality problems, etc., to achieve good wall protection, speed up hole cleaning, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

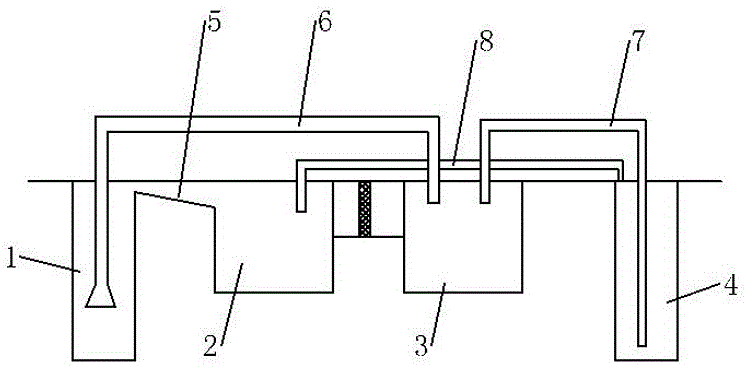

[0008] refer to figure 1 As shown, the composite pile foundation construction site structure provided by the present invention includes the first pile hole 1 formed by the percussion drill holes distributed in sequence in the horizontal direction, the mud sedimentation tank 2, the mud reserve pool 3 and the second pile hole formed by the rotary drilling drill holes. The pile hole 4, the first pile hole 1 and the mud sedimentation tank 2 are connected by an oblique groove 5, and the oblique groove 5 is distributed near the first pile hole 1 with one end high and the other end low, and the mud The sedimentation tank 2 and the mud reserve tank 3 are connected through a channel configured with a filter screen, and the first pile hole 1 and the mud sedimentation tank 2 are connected through the first external pipeline 6, and the first external pipeline 6 is configured to transport the muddy water To the pump of the first pile hole 1, the mud reserve tank 3 is connected with a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com