Cement-soil preparation system suitable for different fluidity and soil

A preparation system and fluidity technology, which is applied in the direction of clay preparation equipment, cement mixing equipment, mixing operation control, etc., can solve the problems of long mixing time, uneven mixing of cement and soil, and affecting the construction period, so as to achieve uniform cement composite soil and not easy Layered separation, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

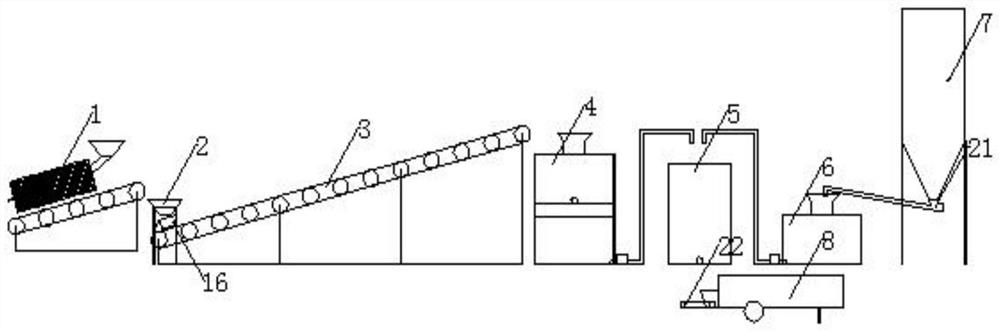

[0045] The present invention will be further described below in conjunction with accompanying drawing and embodiment, the overall structure of the present invention is as follows figure 1 shown, including:

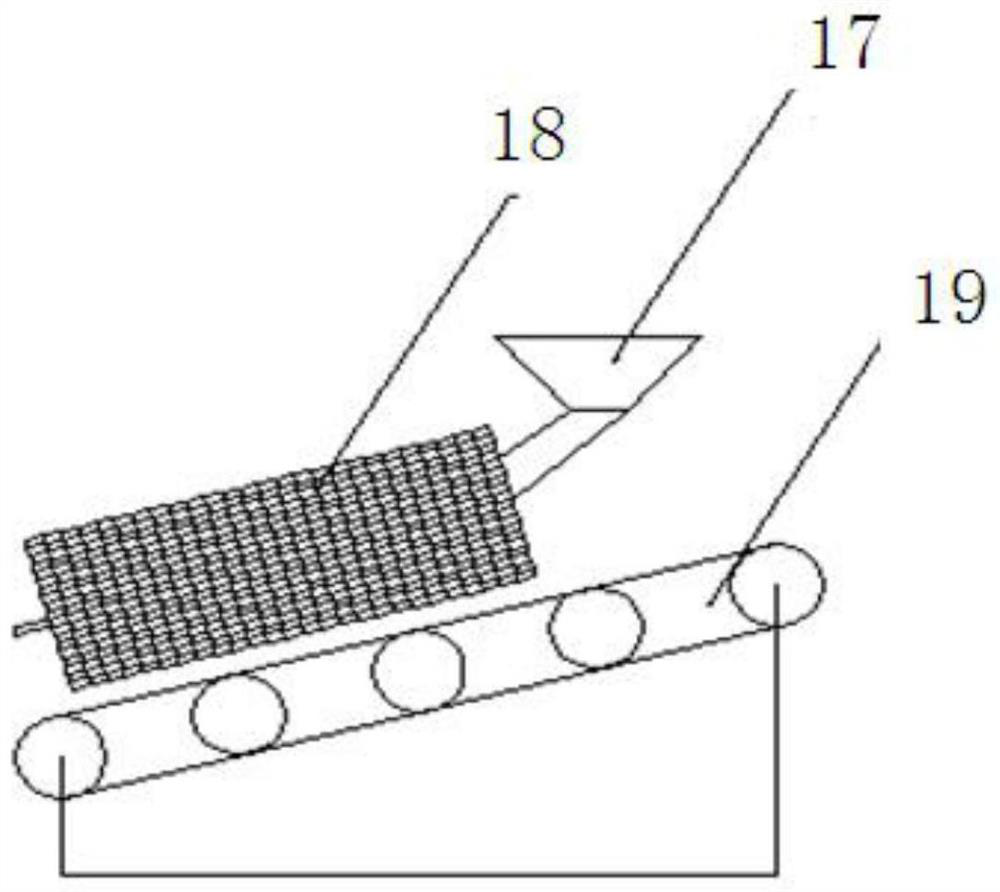

[0046] Soil material screening machine 1 is used to screen the soil material, and the sieved soil material is sent to the soil material metering bin through the conveyor belt 19;

[0047] The soil material weighing bin 2 weighs a certain amount of soil material according to the set weight, and the weighed soil material is sent to the mud mixing station through the conveyor belt conveyor 3;

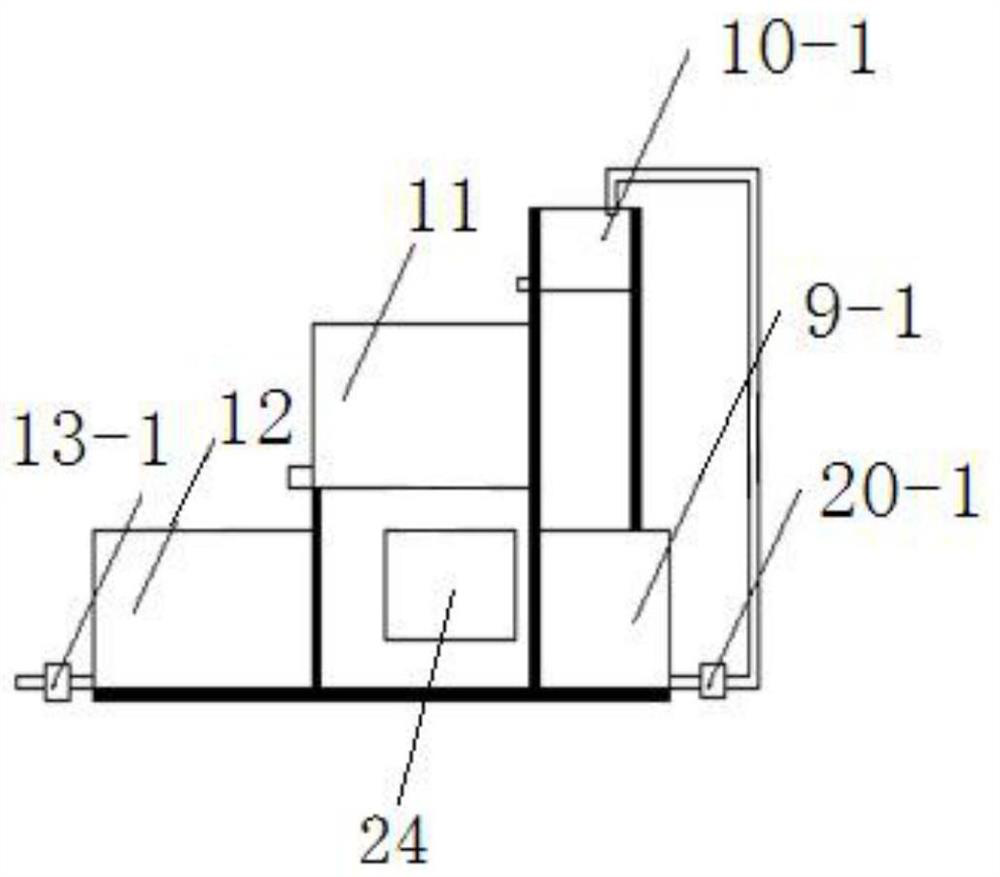

[0048] A mud mixing station 4, the mud mixing station includes a mixer, one side of the mixer is equipped with a water storage tank I communicated with it, the communication circuit between the water storage tank I and the mixer is provided with a water metering bin I, The water metering bin 1 supplies water to the mixer according to the set amount, and the mud stirred by the mixer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com