Connection structure and method of prefabricated column and beam-slab joints in concrete frame structure

A frame structure and prefabricated column technology, applied in building construction, construction, etc., can solve the problems of limited working space, difficult positioning, difficult operation, etc., to reduce the amount of concrete pouring, reduce the time for drying and hardening, and improve the shear resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

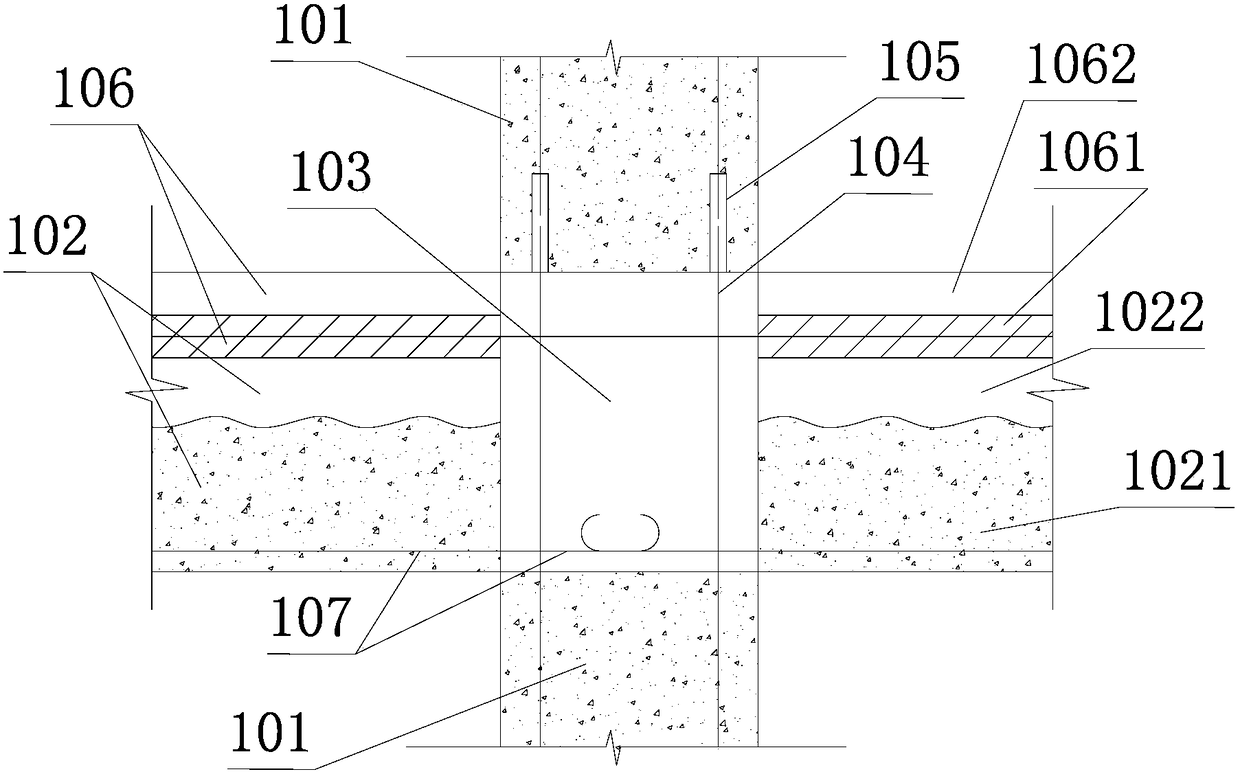

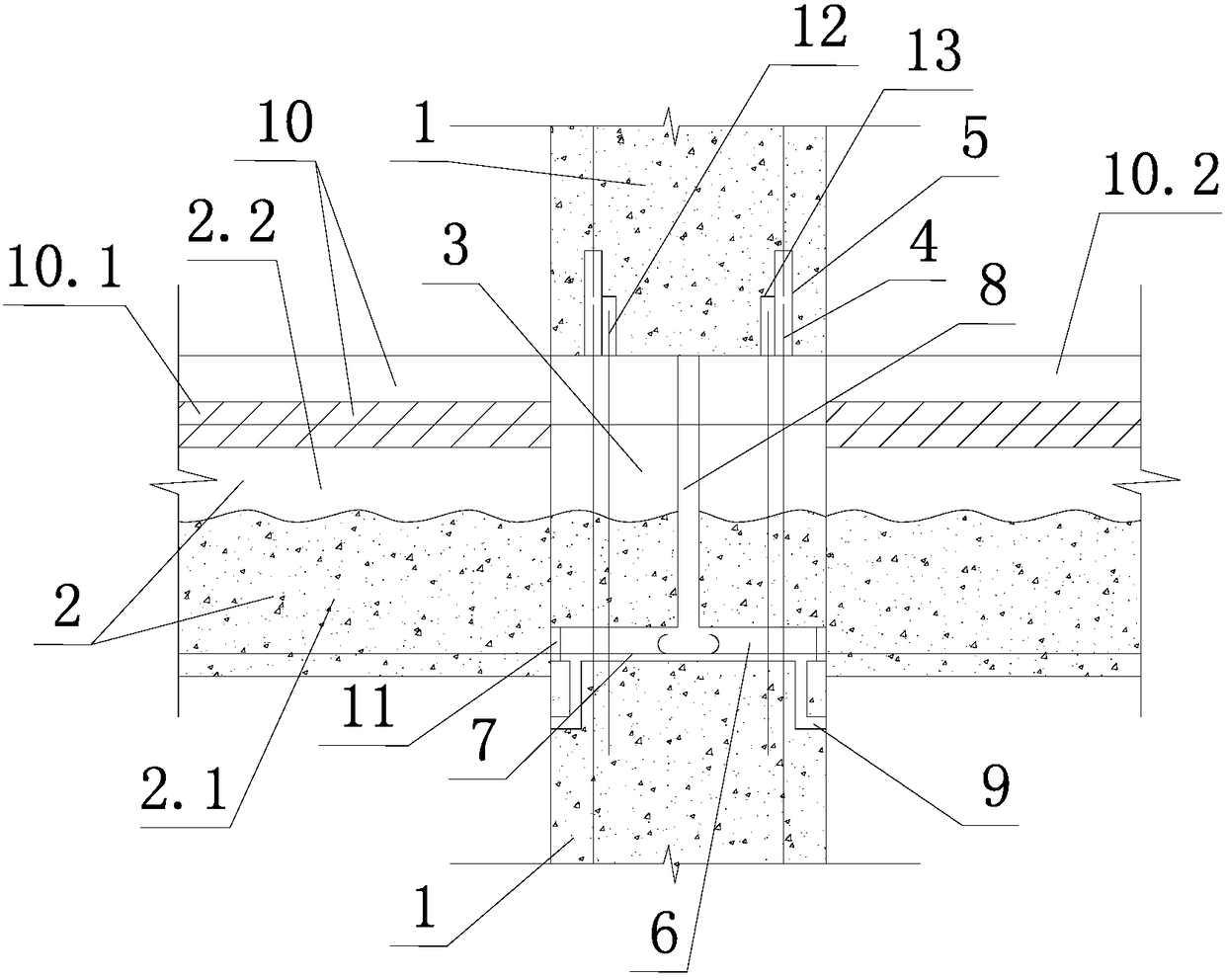

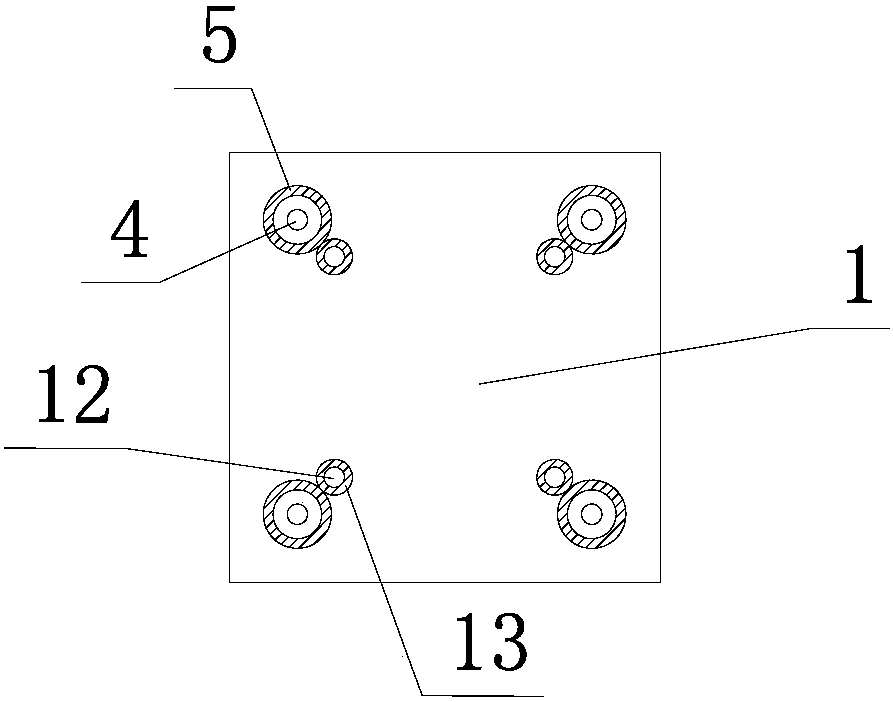

[0024] Such as figure 2 , image 3As shown, the connection structure between the prefabricated column and the beam-slab node of the concrete frame structure of the present invention includes the prefabricated column 1 below, the prefabricated column 1 above, the composite beam 2 on both sides and the upper and lower prefabricated columns 1 and two The node area 3 between the side laminated beams 2 is poured with concrete. Sometimes, there are not only two composite beams 2 in the node area 3, but four composite beams 2 perpendicular to each other are butted. Each composite beam 2 is formed by laminating a lower prefabricated beam 2.1 and an upper cast-in-place beam 2.2. The lower prefabricated column 1 is anchored with a vertical stressed steel bar 4 , and the vertical stressed steel bar 4 passes through the concrete in the node area 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com