Gear shifting control method and system of automatic transmission and vehicle

A technology of automatic transmission, control method, applied in the direction of transmission control, elements with teeth, belt/chain/gear, etc., can solve the problems of not taking into account the speed of the joint sleeve, increasing the shifting time, not taking into account, etc., Achieve smooth shifting process, improve shifting quality and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

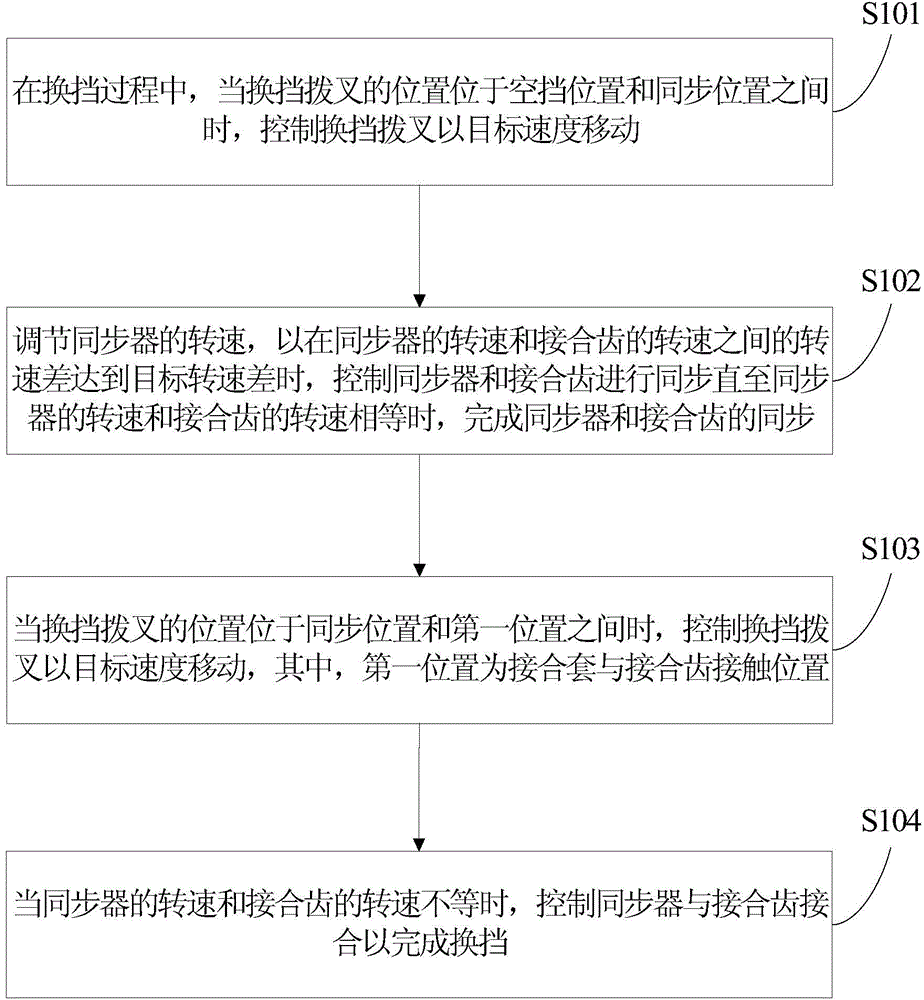

[0033] figure 1 It is a flowchart of a shift control method of an automatic transmission according to an embodiment of the present invention.

[0034] Such as figure 1 As shown, the shift control method of an automatic transmission according to an embodiment of the present invention includes the following steps:

[0035] Step S101: During the shifting process, when the position of the shift fork is between the neutral position X1 and the synchronous position X2, control the shift fork to move at a target speed. In one embodiment of the present invention, the position of the shift fork can be collected by a position sensor.

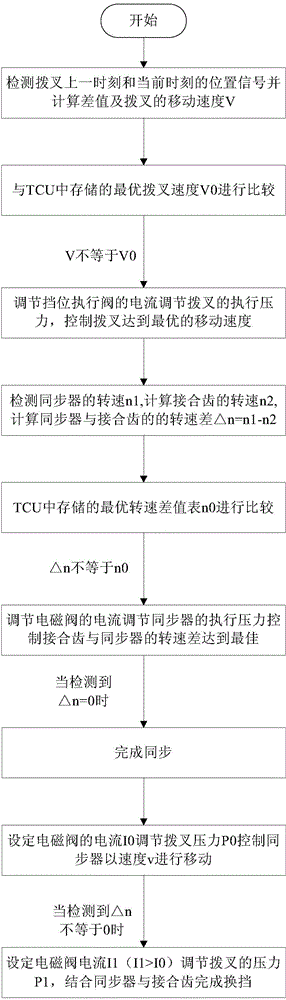

[0036] Specifically, as figure 2 As shown, step S101 spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com