Vehicle lighting device and fabrication method thereof

A technology for lighting devices and vehicles, applied in lighting devices, fixed lighting devices, cooling/heating devices of lighting devices, etc., can solve problems such as small contact area and low heat dissipation efficiency, and achieve improved heat dissipation efficiency and good heat conduction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

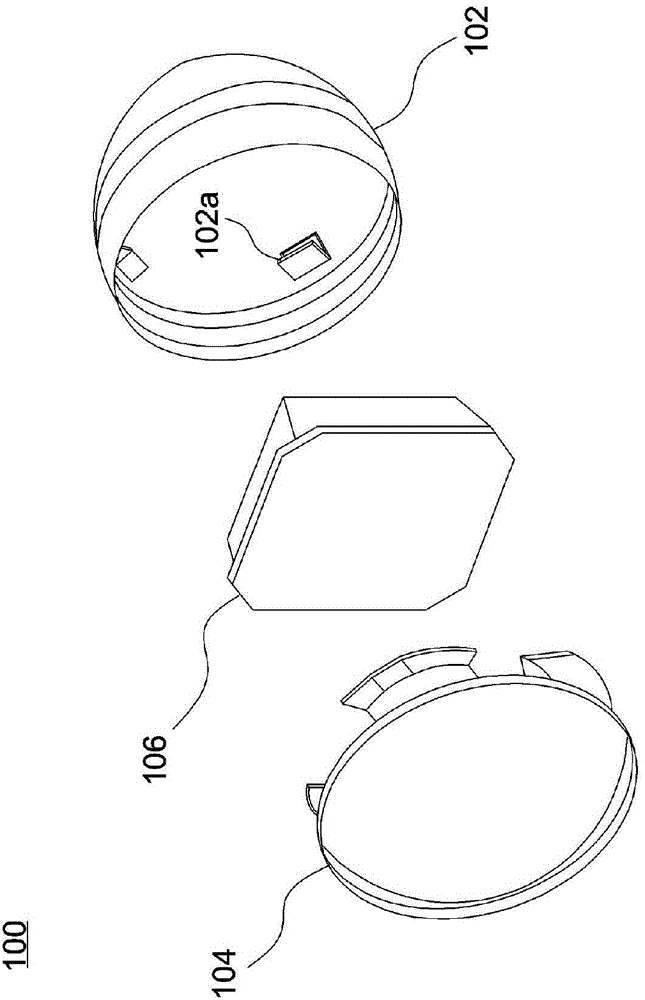

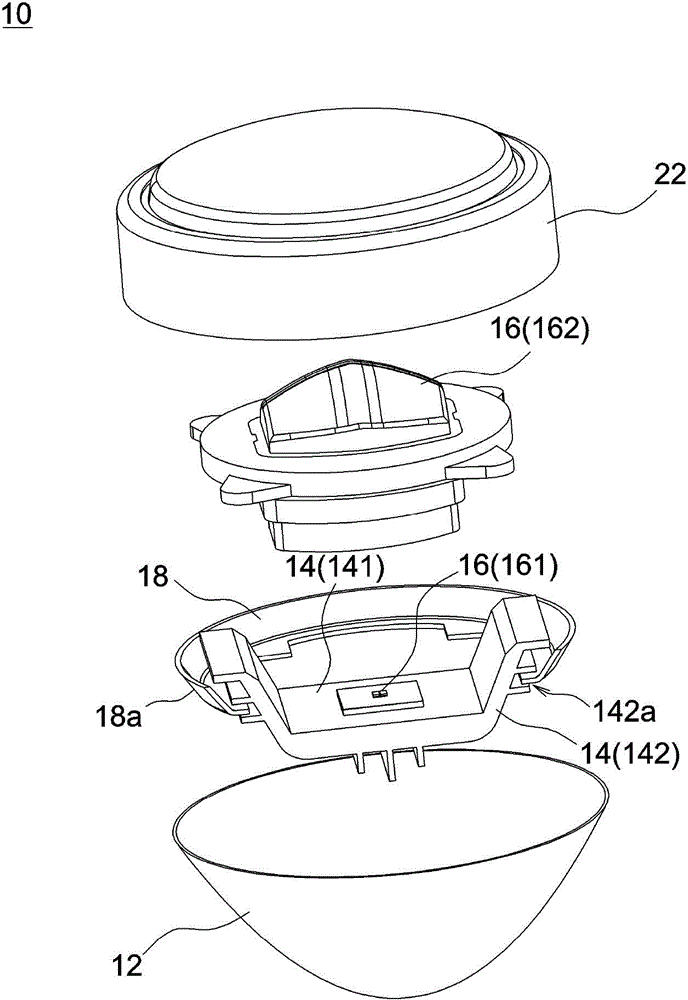

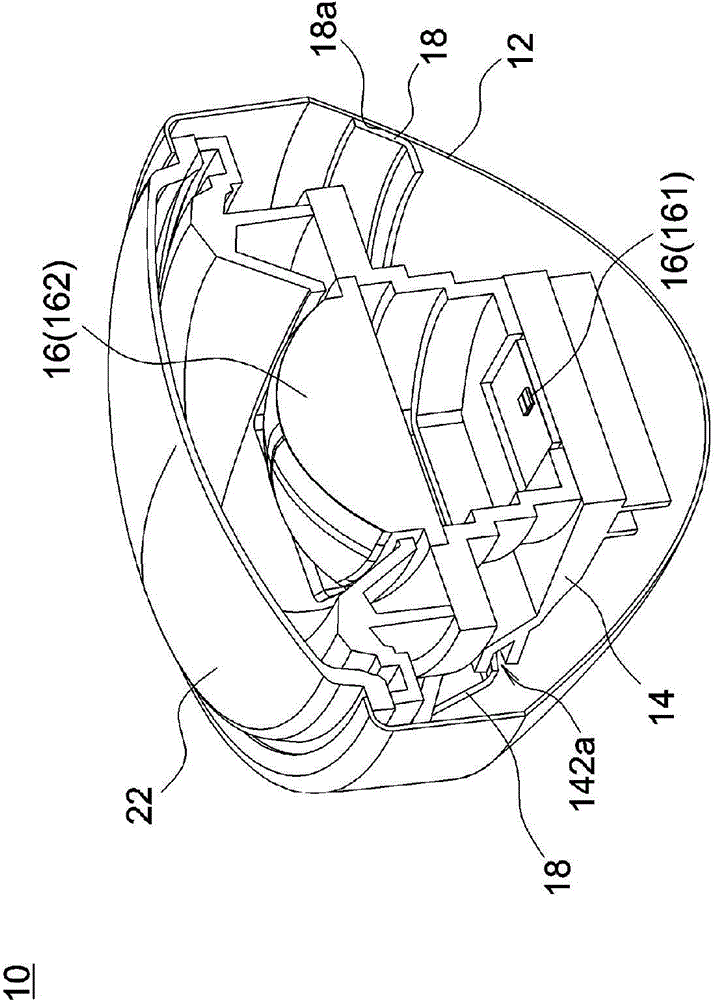

[0026] figure 2 It is an exploded view of components of a vehicle lighting device 10 according to an embodiment of the present invention, image 3 for figure 2 The cross-sectional schematic diagram of the vehicle lighting device after assembly. Such as figure 2 and image 3 As shown, a vehicle lighting device 10 includes a lamp housing 12, a heat sink 14, a light source assembly 16 and a flexible member 18, the heat sink 14 is accommodated in the lamp housing 12, and the light source assembly 16 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com