Heat-conducting ultrahigh-voltage-resistant insulating composite material and preparation method thereof

An insulating composite material, thermal insulation technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of reducing high voltage resistance, achieve excellent thermal conductivity, high thermal conductivity, excellent resistance The effect of ultra-high voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

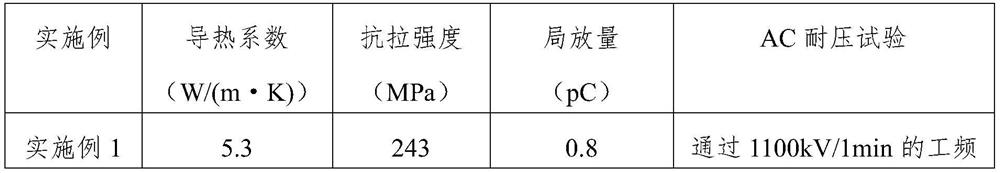

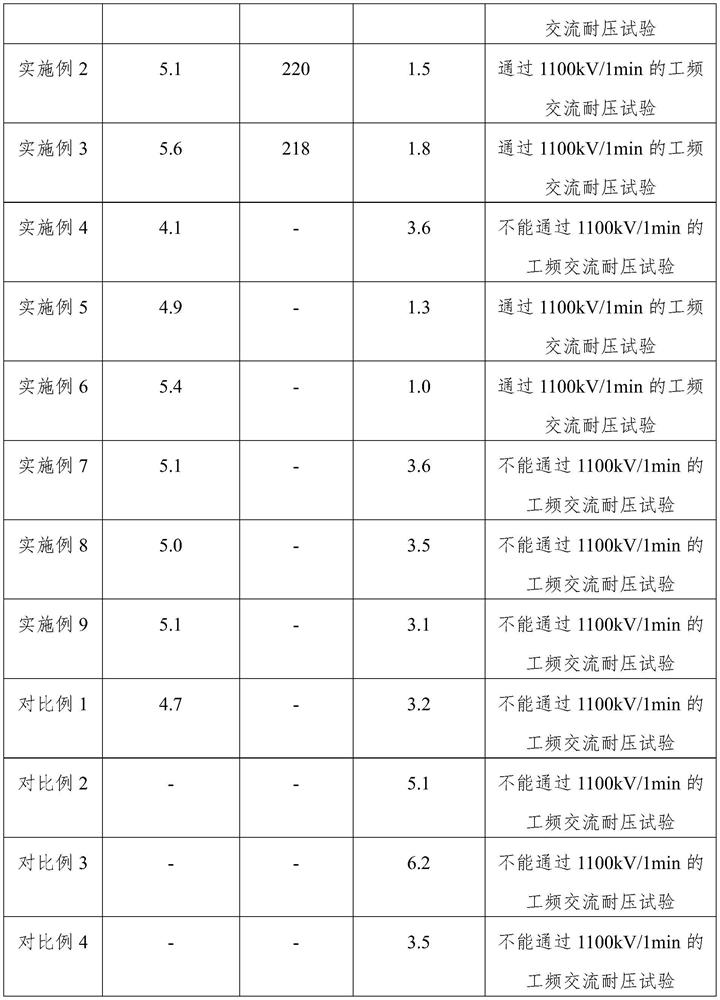

Examples

preparation example Construction

[0031] The present invention provides, in a first aspect, a preparation method of a thermally conductive type ultra-high voltage-resistant insulating composite material, the preparation method comprising the following steps:

[0032] (1) Ball-milling the thermally conductive and insulating ceramic powder with a solvent to obtain a thermally conductive and insulating ceramic dispersion; the present invention has no particular restrictions on the particle size of the thermally conductive and insulating ceramic powder. In some specific embodiments, preferably , the average particle size of the thermally conductive and insulating ceramic powder is 1 to 2 μm; in the present invention, preferably, the mass ratio of the thermally conductive and insulating ceramic powder to the solvent is (1 to 2): (7 to 8) (for example, 1:7, 1:8, 2:7 or 2:8); the present invention has no special requirements for the solvent, and the solvent can be, for example, ethanol, acetone or other solvents that ...

Embodiment 1

[0069] Step 1: Preparation of Thermally Conductive Insulating Ceramic Dispersion

[0070]The thermally conductive and insulating ceramic powder (the thermally conductive and insulating ceramic powder prepared by mixing boron nitride and aluminum nitride with a mass ratio of 1:3) and ethanol with a mass ratio of 2:8 were added to the ball mill tank, and the ball mill was carried out with a planetary ball mill. , the speed of the ball mill is controlled at 400 rpm, and the ball milling time is 15 hours to prepare a thermally conductive and insulating ceramic dispersion.

[0071] Step 2: Prepare a mixture of thermally conductive and insulating ceramic dispersion and matrix resin

[0072] Mix the above-mentioned thermally conductive and insulating ceramic dispersion liquid with epoxy resin (E51 epoxy resin) according to a mass ratio of 100:30, and stir at room temperature for 2.5 hours to obtain a uniformly mixed mixture.

[0073] Step 3: Preparation of thermally conductive and i...

Embodiment 2

[0084] Embodiment 2 is basically the same as Embodiment 1, except that:

[0085] In step 1: the thermally conductive and insulating ceramic powder is boron nitride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com