Fused epoxy powder material, coated steel pipe and preparation method and application thereof

A technology for sintering epoxy powder and steel pipe, applied in powder coatings, epoxy resin coatings, coatings, etc., can solve the problems of thin color marking lines, reduce connection efficiency, affect abnormal processing efficiency, etc., achieve the best antistatic, Improved dispersibility and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

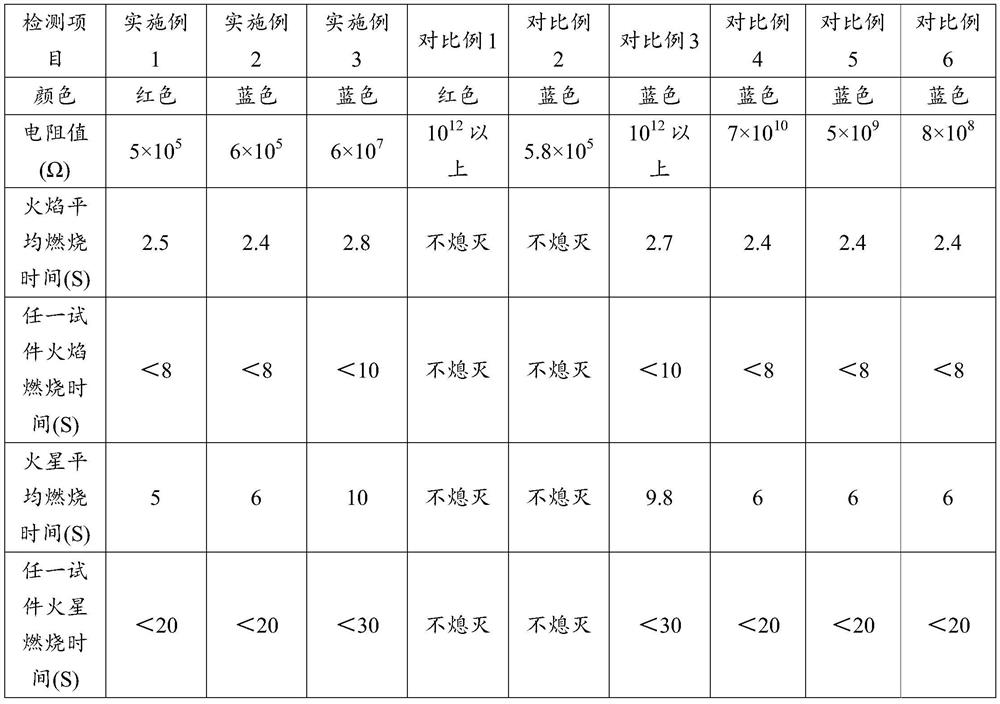

Examples

Embodiment 1

[0042] a: Preparation of antistatic flame retardant masterbatch. The ratio by mass is: 20 parts of nano-carbon fiber, 10 parts of conductive mica, 5 parts of conductive titanium dioxide, 10 parts of brominated flame retardant, 1 part of powder coupling agent, bisphenol A epoxy resin (604) 54 share. After mixing various raw materials by a high-speed mixer, a sheet is prepared by a twin-screw extruder and a tablet press, and then crushed by an ACM mill to prepare an antistatic and flame-retardant masterbatch with a particle size of 50 mesh.

[0043] b: Preparation of fusion-bonded epoxy powder with red antistatic and flame-resistant properties. The ratio by mass is: 50 parts of bisphenol A epoxy resin (604), 10 parts of phenolic curing agent (Daqing Qinglu 969F02X), 20 parts of antistatic and flame retardant masterbatch, accelerator (2-methylimidazole ) 0.1 part, leveling agent additive (Wuhan Yincai L88) 1 part, defoamer (benzoin) 0.6 part, nano filler (nano silica) 16 parts,...

Embodiment 2

[0046] a: Preparation of antistatic flame retardant masterbatch. The ratio by mass is: 20 parts of nano-carbon fiber, 10 parts of conductive mica, 5 parts of conductive titanium dioxide, 10 parts of brominated flame retardant, 1 part of powder coupling agent, bisphenol A epoxy resin (604) 54 share. After mixing various raw materials by a high-speed mixer, a sheet is prepared by a twin-screw extruder and a tablet press, and then crushed by an ACM mill to prepare an antistatic and flame-retardant masterbatch with a particle size of 50 mesh.

[0047] b: Preparation of fusion-bonded epoxy powder with blue antistatic and flame-resistant properties. The ratio by mass is: 50 parts of bisphenol A epoxy resin (604), 10 parts of phenolic curing agent (Daqing Qinglu 969F02X), 20 parts of antistatic and flame retardant masterbatch, accelerator (2-methylimidazole ) 0.1 part, leveling agent additive (Wuhan Yincai L88) 1 part, defoamer (benzoin) 0.6 part, nano filler (nano silicon dioxide)...

Embodiment 3

[0050] a: Preparation of antistatic flame retardant masterbatch. The ratio by mass is: 10 parts of nano-carbon fiber, 10 parts of conductive mica, 20 parts of conductive titanium dioxide, 10 parts of brominated flame retardant, 1 part of powder coupling agent, bisphenol A epoxy resin (604) 49 share. After mixing various raw materials by a high-speed mixer, a sheet is prepared by a twin-screw extruder and a tablet press, and then crushed by an ACM mill to prepare an antistatic and flame-retardant masterbatch with a particle size of 50 mesh.

[0051] b: Preparation of fusion-bonded epoxy powder with blue antistatic and flame-resistant properties. The ratio by mass is: 50 parts of bisphenol A epoxy resin (604), 10 parts of phenolic curing agent (Daqing Qinglu 969F02X), 20 parts of antistatic and flame retardant masterbatch, accelerator (2-methylimidazole ) 0.1 part, leveling agent additive (Wuhan Yincai L88) 1 part, defoamer (benzoin) 0.6 part, nano filler (nano silicon dioxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com