Synthesis method of superfine aluminum hypophosphite

A synthesis method and technology of aluminum hypophosphite, applied in the field of flame retardants, can solve the problems of serious environmental pollution, high production energy consumption and high cost, and achieve the effects of uniform particle size, low cost and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

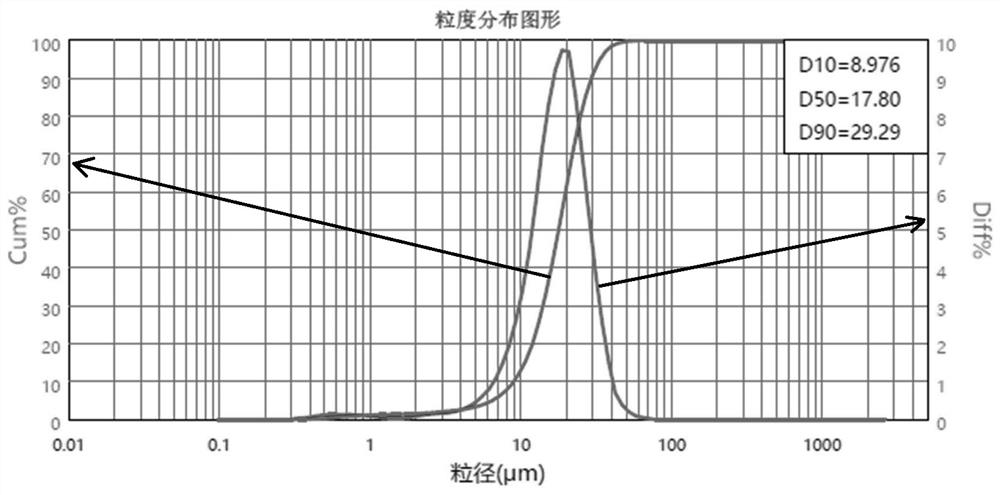

[0027] Add 100 kg of sodium hypophosphite monohydrate into a 500L reactor, add 200 kg of water, and heat to 85°C to dissolve completely. Add 0.20 kg of polycarboxylate sodium salt and 0.20 kg of sodium hexametaphosphate to the reaction solution and stir for 0.5 hour, stir evenly, the aqueous solution of aluminum chloride (the quality of aluminum chloride and water are respectively 43 kg and 72 kg) to the reaction solution Add dropwise into the liquid, after the dropwise addition is completed, keep warm for 0.5 hours, lower to 50°C, centrifuge, wash with water, and dry to collect the product. Obtain 64.2 kilograms of superfine aluminum hypophosphite flame retardants, and the productive rate is 92%. The particle size of the product is 17.8 μm for D50 and 26.34 μm for D90. see test results figure 1 Particle size distribution diagram.

[0028] Product particle size test results are shown in Table 1:

[0029]

Embodiment 2

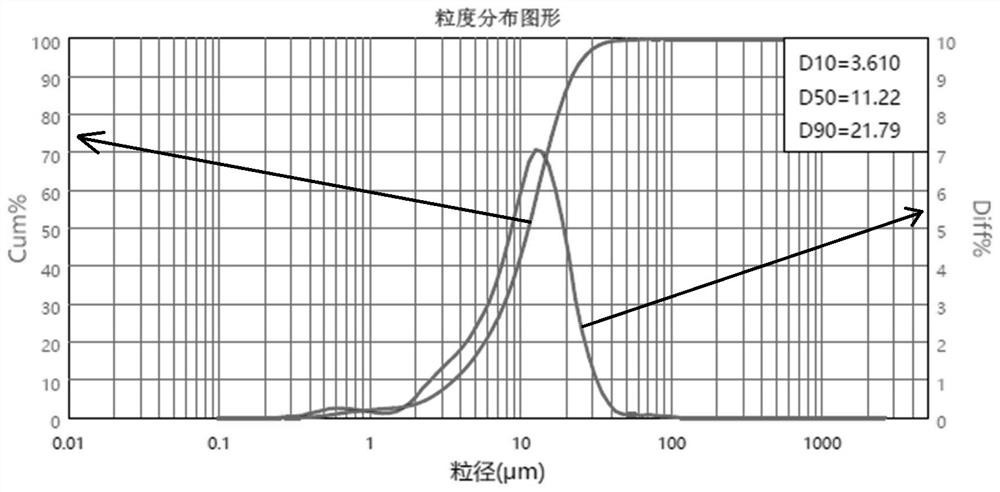

[0031] Add 100 kg of sodium hypophosphite monohydrate into a 500L reactor, add 100 kg of water, and heat to 85°C to dissolve completely. Add 0.30 kg of polycarboxylate sodium salt and 0.2 kg of sodium hexametaphosphate to the reaction solution and stir for 0.5 hour, stir evenly, the aqueous solution of aluminum chloride (the quality of aluminum chloride and water are respectively 44 kg and 100 kg) to the reaction solution Add dropwise into the solution, after the dropwise addition, keep warm for 0.5 hours, lower to 50°C, centrifuge, wash with water, and dry to collect the product. Obtain 65.59 kilograms of superfine aluminum hypophosphite flame retardants, and the productive rate is 94%. The particle size of the product is 11.22 μm for D50 and 21.79 μm for D90. see test results figure 2 Particle size distribution diagram.

[0032] Product particle size test results are shown in Table 2:

[0033]

[0034]

Embodiment 3

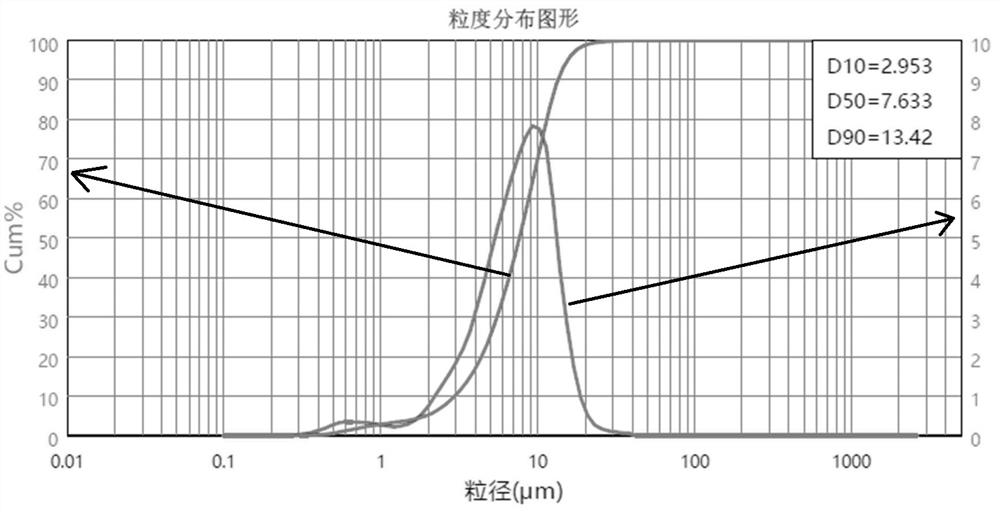

[0036] Add 100 kg of sodium hypophosphite monohydrate into a 500L reactor, add 50 kg of water, and heat to 85°C to dissolve completely. Add 0.2kg compound sodium phosphate to the reaction solution (complex sodium phosphate is sodium citrate: sodium pyrophosphate: glycerol is compounded according to the molar ratio of 4:5:1.) and 0.2kg polycarboxylate sodium salt are stirred and stirred evenly , the aqueous solution of aluminum chloride (the quality of aluminum chloride and water are respectively 44 kg and 100 kg) is added dropwise to the reaction solution, after the dropwise addition is completed, keep warm for 0.5 hours, drop to 50°C, centrifuge, wash with water, dry and collect product. Obtained 66.8 kilograms of superfine aluminum hypophosphite flame retardants, and the yield was 95.7%. The particle size of the product is 7.633 μm for D50 and 13.42 μm for D90. see test results image 3 Particle size distribution diagram.

[0037] Product particle size test results are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com